Flush mounting – Kaman KD-2300 User Manual

Page 23

20

••••

Part III: The Equipment

KD-2300 Instruction Manual

Flush Mounting

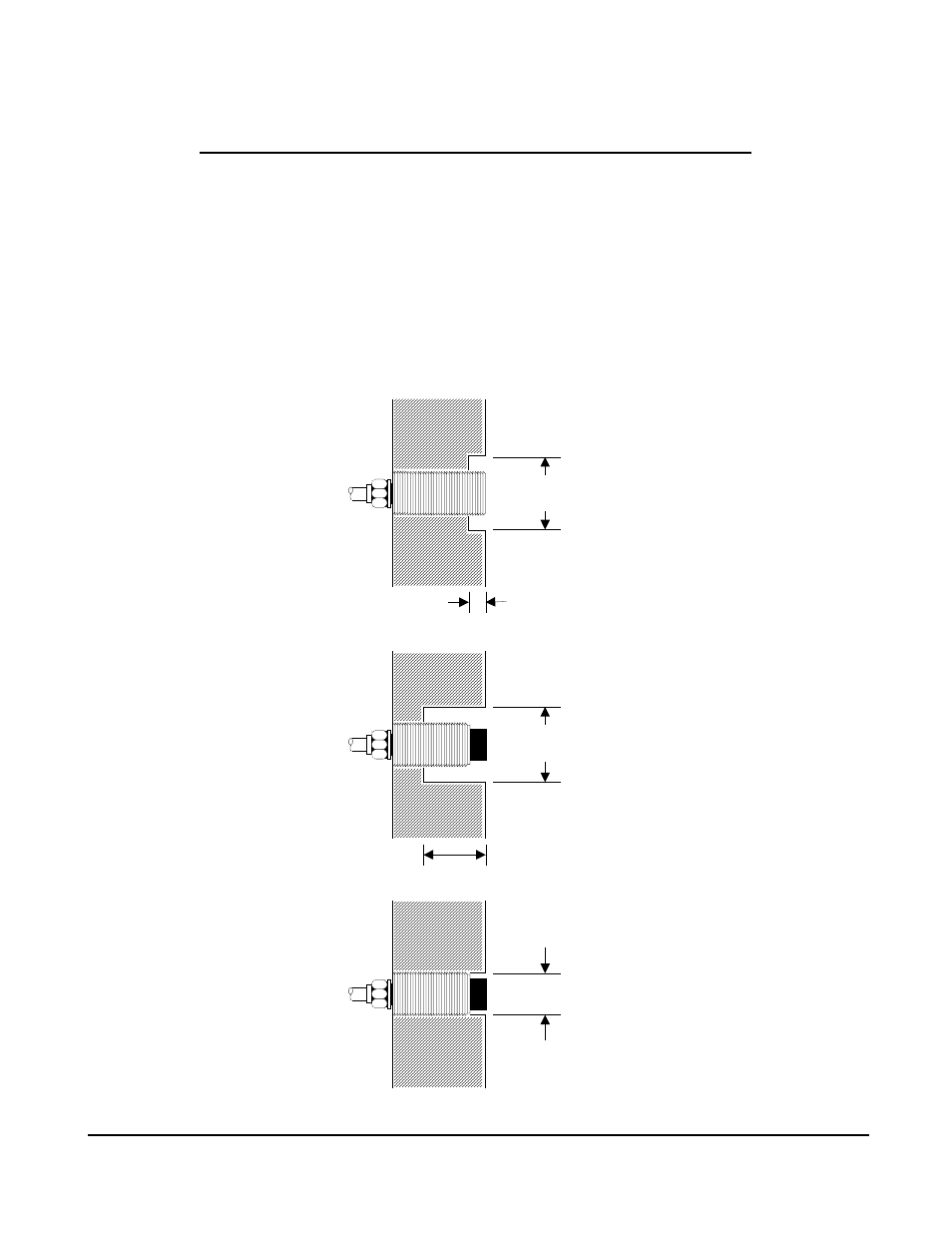

Flush mounting in a conductive fixture requires a cut-out area around the sensor

head. The depth and width of the cutout are relative to sensor face diameter as

shown in the diagram below. The cutout should never be any smaller than the

dimensions arrived at by making these calculations. Smaller width and/or depth

can result in loading effects so severe that you may not be able to calibrate the

system. The cut-out area may serve as a collection point for refuse, metal filings,

cutting oils, coolants, etc. It may also disrupt the gaseous or liquid flow patterns

in the measurement area. You can effectively solve this problem by backfilling

the cut-out area with a nonconductive material, such as silicon rubber or epoxy.

1.5 TO 2 X

SENSOR DIAMETER

0.25 TO 0.5 X

SENSOR DIAMETER

2.5 TO 3 X

SENSOR DIAMETER

1.5 to 2 X

SENSOR DIAMETER

SENSOR

DIAMETER

NOT

RECOMMENDED

FULL SHIELD

PARTIAL SHIELD