Cable – Dwyer 275 User Manual

Page 4

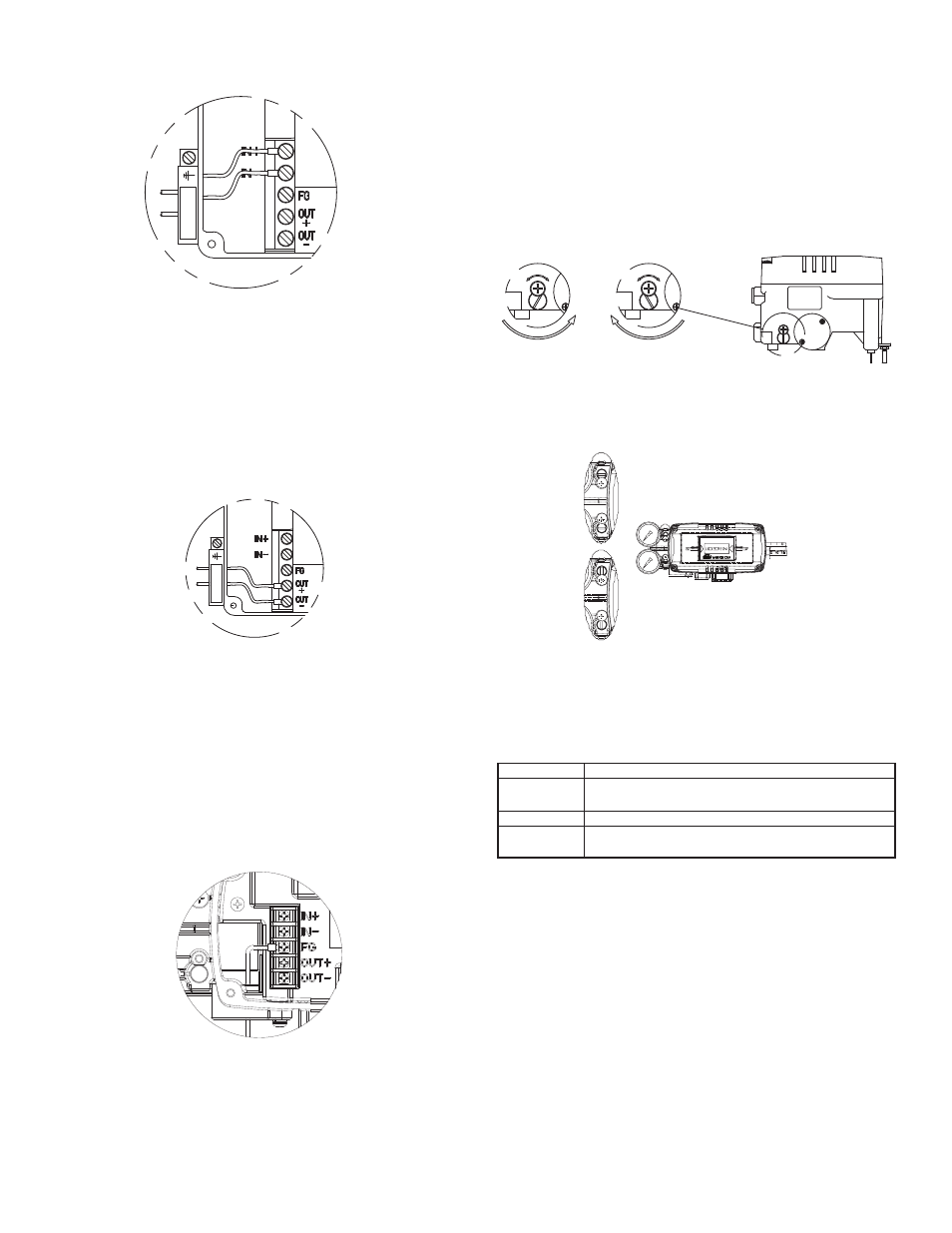

Terminal Connection of Current Input Signal

1. Open cover by loosening the four screws on positioner cover.

2. Loosen locking bolts of terminal plate.

3. Insert a cable through the cable connector in the positioner.

4. Use a ring type cable terminal so that it does not come out.

5. Insert terminal bolts in terminal holes of cable and lock them with (+)

terminal and (–) terminals on the terminal plate. Tighten terminal bolts

with 1.1 lbs-ft (15 kfgcm) torque.

6. Be sure not to change the polarity of terminals.

Terminal Connection of Feedback Signal

1. Open cover by loosening the four screws on the positioner cover.

2. Loosen terminal locking bolts of feedback signal terminals.

3. Insert a cable through the cable connector in the positioner.

4. Use a ring type cable terminal so it does not come out.

5. Insert terminal bolts in terminal holes of cable and lock them with (+)

terminal and (–) terminals on the terminal plate. Tighten terminal

bolts with 1.1 lbs-ft (15 kfgcm) torque.

6. Be sure not to change polarity of terminals.

Inner Terminal Connection for Ground

1. The ground is necessary for the safety of the positioner and system.

2. The ground terminals are inside the terminal in the center of the

terminal plate and outside terminal beside outer cable entry. Use any

ground terminal that is available. Resistance must be less than 100

Ohm.

3. For use with inside ground, open cover by loosening the four screws

of positioner cover.

4. In order to maintain the ground connection, use a ring type ground

cable terminal to prevent it from coming out.

A/M Switch (Auto/Manual switch)

The A/M switch is located on the bottom of the Series 275 positioners.

When set to auto, supply pressure is transmitted to actuator by the

operation of the positioner. When set to manual, supply pressure of

air filter regulator is transmitted to actuator regardless of positioner.

* When A/M switch is set to manual, make sure that supply pressure

range is not exceeded.

1. Make sure supply pressure is within range.

2. Turn switch clockwise and supply pressure of air filter regulator is

transmitted to actuator.

3. Turn switch counter-clockwise to operate positioner manually.

Variable Orifice

Hunting can occur if the actuator volume is too small. In this case, adjust

the variable orifice using a (-) flathead screwdriver. Hunting is prevented

by reducing the flow rate of supply pressure transmitted to actuator.

Auto Calibration and Basic Operations

Warning: Since this makes the valve or actuator move, before auto

calibration, the valve must be separated from entire system.

Buttons Operations

Series 275 positioners perform various functions using four buttons. The

position of the buttons is shown below:

page 4

Terminal connection of input current signal

CABLE

Terminal connection of transmitter

CABLE

Ground terminal connection

A

M

A

M

AUTO

MANUAL

Maximum Open

Minimum Open

Button

Function

Enter to main menu and sub-menus, save adjusted

parameter values, etc.

Return to previous menu

Move to next menu, change parameter values, etc.