Dwyer 275 User Manual

Page 2

Series 275 Installation

Series 275 is designed for rotary motion valves such as Dwyer

Instruments ball and butterfly valves using rack and pinion, scotch yoke

or complex type actuators whose stem is rotated 90°. Series 275 p -

ositioners consist of the following components:

1. Series 275 main body

2. Fork lever and lever spring to attach on actuator

3. 1 bracket

4. Four hex bolts M8x1.25P

5. Four M8 plate washers

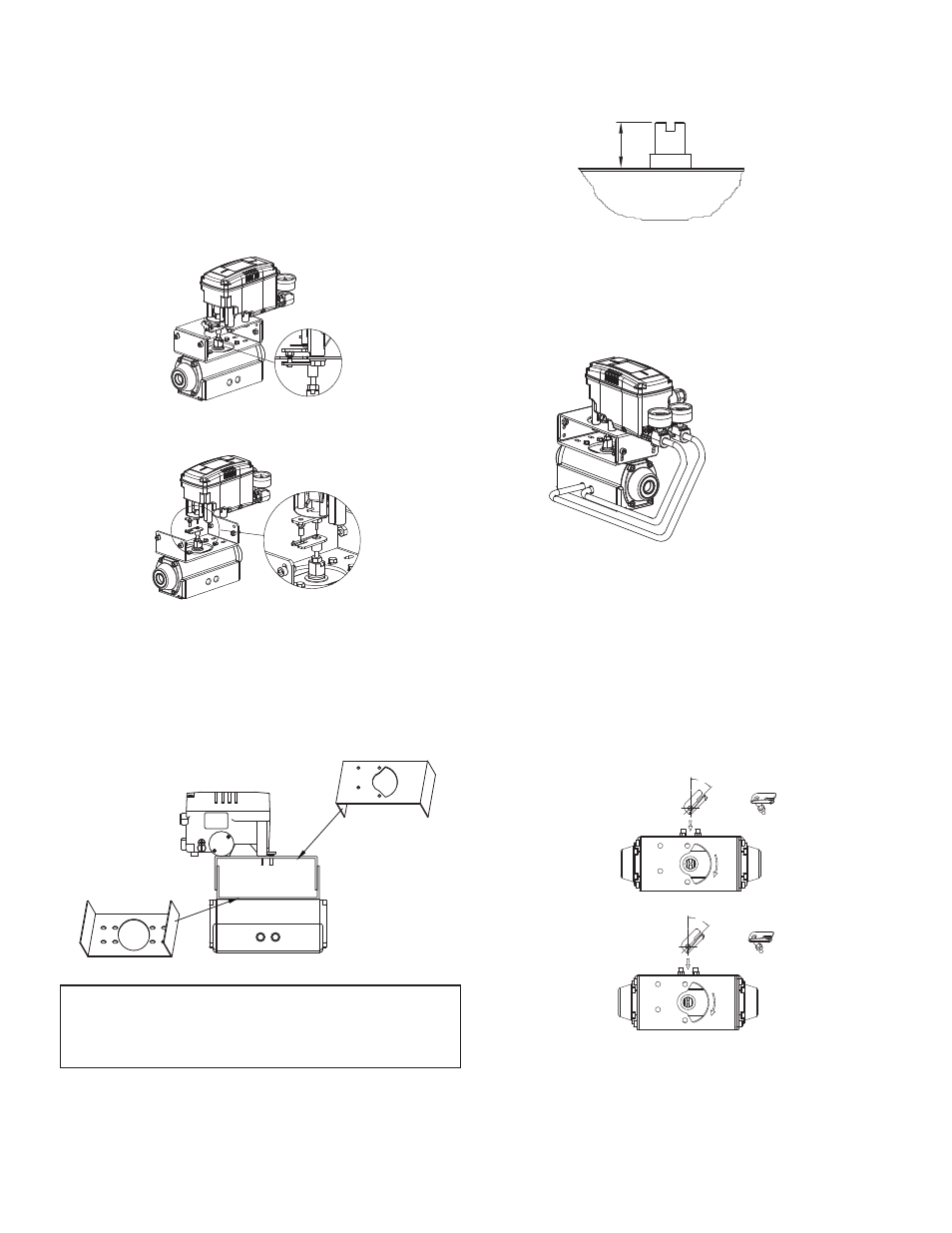

Installing Series 275 with bracket

Series 275 is supplied with a standard bracket. The bracket consists of

two parts and is used with a NAMUR shaft. The bracket is assembled in

the factory based on 0.79˝ (20 mm) of actuator stem height. If the

actuator stem height is higher, such as 1.18˝ (30 mm), or 1.97˝ (50 mm),

reassemble the bracket adjusting to the actuator stem height. Refer to

the table below to check hole positions.

Ex) If H is 30 mm, A-L should be locked in H:30 hole, B-L in H:20,30, A-

R in H:30, and B-R in H:20,30 with bolts.

1. Typical actuator stem heights (H) are 0.79, 1.18 and 1.97 inches (20,

30, and 50 mm). After checking H, assemble brackets following

previous guidelines. The bracket is set at 0.79˝ (20 mm) in the

factory.

2. Attach bracket to the actuator using hex bolts. The diameter of the

bracket bolt holes are 0.24˝ (6 mm). Use spring washers or thread

lock compound so the bolts will not be loosened by vibration or

impact. The direction of the bracket varies by operating conditions,

but the normal direction is depicted in the following picture. That is,

when the piping of actuator and Series 275 is as shown in direction

A, the bracket hole and indicator attached on the bottom of the Series

275 main shaft should be mounted in the same direction.

3. Set the rotation position of actuator stem as the initial zero point,

which is 0% stroke. For a spring return type actuator, the actuator

stem is always rotated to the zero point without supply pressure,

making it easy to check the zero point. If the actuator is double-

acting, check whether the rotation direction of the actuator is

clockwise or counter-clockwise or check the rotation direction of the

actuator using supply pressure.

4. Set the actuator stem as the initial zero point and install a fork lever

as shown in the following picture. Confirm the position of initial zero

point when actuator stem is turned clockwise and counter-clockwise.

Installation angle of fork lever should be about 45 degrees based on

the linear shaft. But the angle is not related to NAMUR shaft.

page 2

Series 275 installation example

Series 275 installation example of fork lever

Series 275 installation example of Namur shaft

Bracket assembly method by actuator stem height H

Actuator stem

height (H)

20 mm

30 mm

50 mm

Markings of bolt holes

A-L

H: 20

H: 30

H: 50

B-L

H: 20, 30

H: 20, 30

H: 50

A-R

H: 20

H: 30

H: 50

B-R

H: 20, 30

H: 20, 30

H: 50

20

Actuator Stem (H)

Actuator

Attachment direction of bracket and actuator

Direction A

450

450

Counter-Clockwise

Clockwise