Dwyer instruments, inc, Protocol version channel address used in hart – Dwyer 275 User Manual

Page 10

Error and Warning Code

If there are any problems during the Series 275 positioner operation, you

can check the error and warning code at VIEW mode as follows:

Error Code

This code is displayed when the Series 275 positioner control becomes

impossible. Code C, D applies.

Warning Code

This code is displayed when the positioner control is available but there

is a possibility of malfunction or low accuracy. Code B, F, G, H applies.

MAINTENANCE

The Series 275 PRECISOR

®

III Positioner is not field serviceable and

should be returned if repair is needed (field repair should not be

attempted and may void warranty). Be sure to include a brief description

of the problem plus any relevant application notes. Contact customer

service to receive a return goods authorization number before shipping.

page 10

Options

VERSION

HART V

POL AddR

bIAS VI

OY Od

FULL_OP

FULL_CL

VM NOR

Erro

VALUE 1

Description

Main software version

HART

®

protocol version

Channel address used in HART

®

protocol

BIAS value necessary to motor control (This variable

is used only by manufacturer)

Total using time

But if the product is used less than one minute from

power-on to power-off, it is not added to total time

Full Open Time (sec) of valve

Full Close Time (sec) of valve

Display type of valve stroke on LCD

Either % or number is available

Error or warning code currently occurred.

Refer to the Code table.

Currently controlled I value (This variable is used

only by manufacturer)

Information checked on VIEW mode

Code

A

B

C

D

E

F

G

H

Description and Cause

None

The range of Pv Span – Pv Zero is less than 500.

Operating angle of feedback is too small.

More than 10% error is continued over more than

one minute.

-There’s no valve movement.

-Valve friction is getting too big.

-Setting pressure of regulator is changed.

I value is at I max or min limit.

-Valve friction has changed.

-Setting pressure of regulator has changed.

None

Full Open, Close time is less than one second.

-Actuator size is too small.

Pv is set lower than 100.

-Operating angle of feedback lever is set too big.

Pv is greater than 4000.

-Operating angle of feedback lever is set too big.

Measures

None

-Increase operating angle of feedback lever and

execute AUTO1 calibration.

-Check the pressure setting of air filter regulator.

Adjust it to recommended pressure

Execute BIAS calibration

-Check the pressure setting of air filter regulator.

Adjust it to recommended pressure

Execute BIAS calibration

None

-Use variable orifice.

-Replace actuator to bigger one.

-Adjust operating angle of feedback lever to be smaller

and execute AUTO1 calibration.

-Adjust operating angle of feedback lever to be smaller

and execute AUTO1 calibration.

Used time

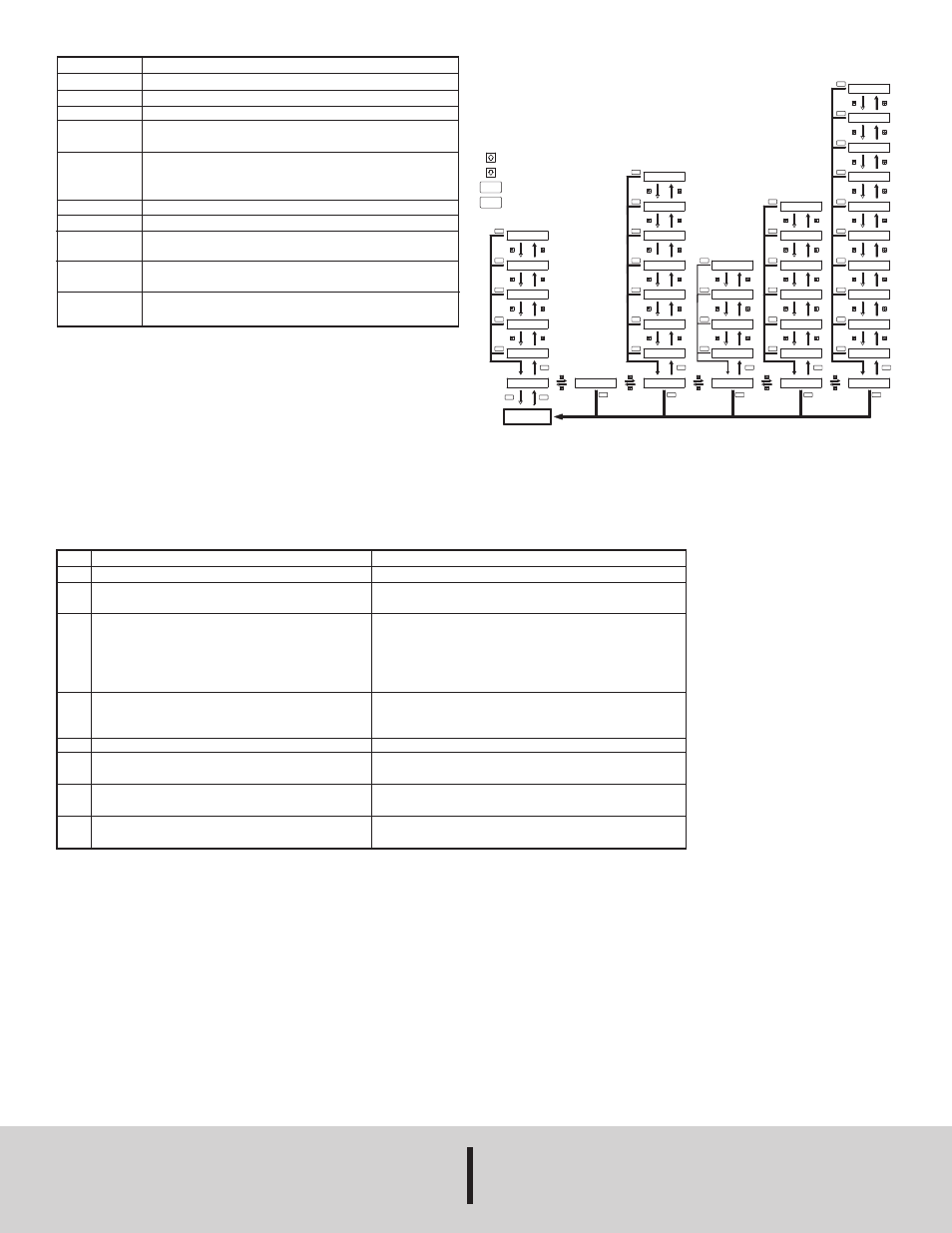

User Set

ENT

: Enter button

Manual Mode

Auto 2

Auto cal

RUN Mode

ENT

(5 sec)

ESC

ESC

Auto 1

ENT

BIAS

Auto 3

ESC

ESC

V_O

ESC

ESC

Hart ver.

Character

K P

End point

View

Valve

Hand cal

Parameter

ESC

ESC

ESC

ESC

ESC

ESC

Start point

Dead Zone

ESC

ESC

ENT

ENT

ESC

Sof ver.

RA / DA

ENT

ENT

BIAS

Tight shut on

TR end point

K D

Tight shut off

TR start point

K I

ESC

ESC

ESC

ESC

ESC

ESC

Polling Add

ESC

ESC

ESC

ESC

ESC

ESC

I value

Split control

ESC

ESC

: Up button

ESC

: Down button

: Esc button

Error code

Full close time

ESC

Full open time

ESC

ESC

View method

ESC

ESC

ESC

ESC

ESC

K I_

K P_

ESC

K D_

Error/Warning code

Copyright 2013 Dwyer Instruments, Inc.

Printed in U.S.A. 6/13

FR# R2-443558-00 Rev. 2

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000

www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Fax: 219/872-9057

e-mail: [email protected]