Dwyer PMT User Manual

Page 24

Particulate Monitoring Systems

Installation & Operating Manual

Document No. 210-1015-F

Page

18

©2007

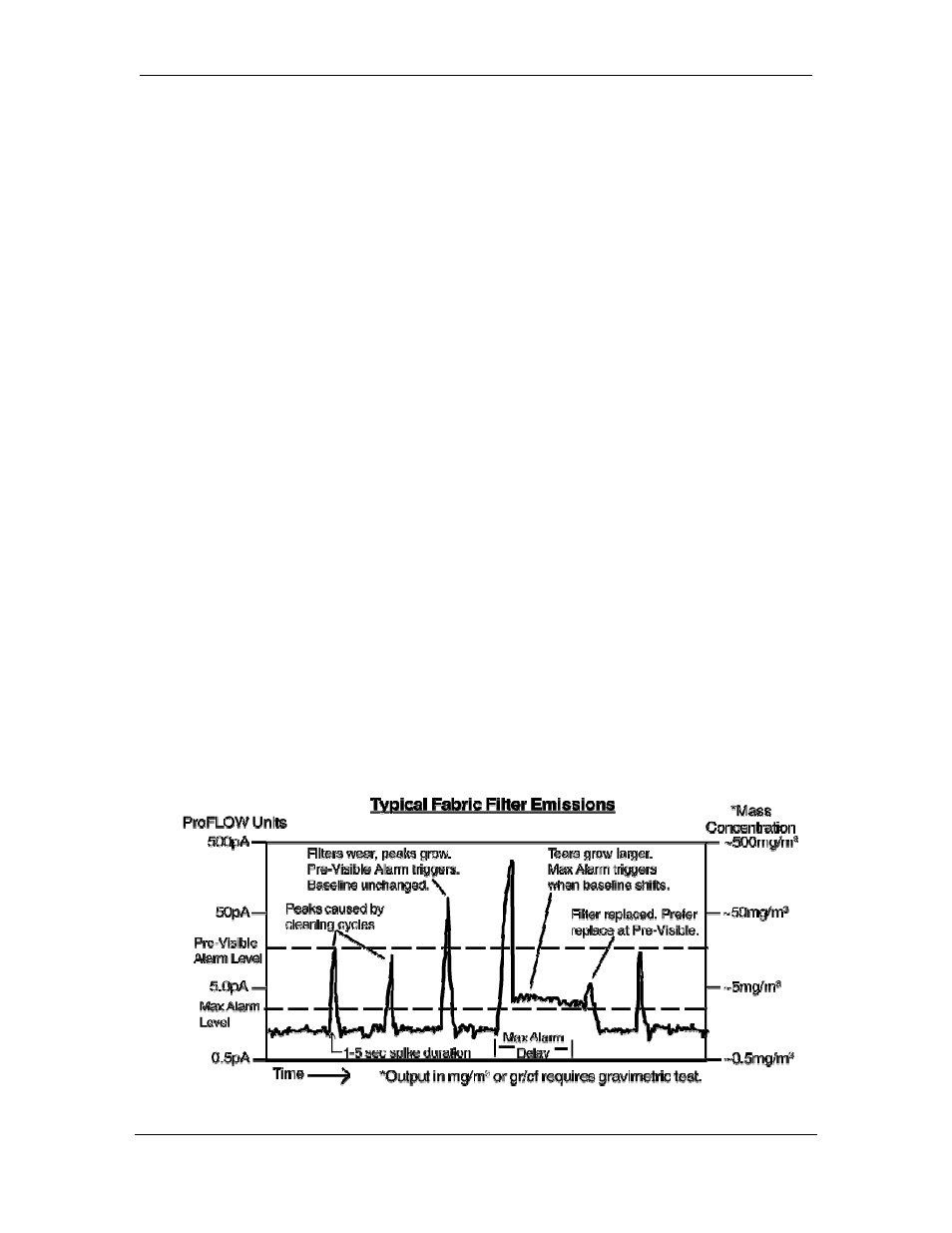

8.2 Alarm Levels for Fabric Filter Applications

In fabric filter applications it is common to use alarms for indicating sustained high readings. Internal

alarms are not included in 4-20mA loop powered transmitter products. Alarming for loop powered

transmitter products is typically a part of an external system such as a PLC or Plant Wide Control

System.

It is recommended to set two separate alarm levels. One alarm should be set based on the average base

line reading and another alarm should set based on the peak readings following cleaning cycles.

Normally, Alarm #1 is used for detecting sustained increases in the base line reading. For example a

baghouse that has new, highly-efficient filters may have an average baseline reading of 10-20pA. It

would then be recommend to set the baseline alarm at 30-50pA with an alarm delay time that was

long enough so that cleaning cycle peaks did not activate the baseline alarm. Each application can be

different (for example much higher readings are possible with larger, older baghouses) and each plant

may have different operating demands in terms of how sensitive the alarms should be set. It is,

therefore, recommended to initially set the alarm as low as possible and to trend and data log the

readings over time before finalizing the settings. Correlations to stack test data can also be

incorporated to correlate the output to actual mass concentration to set more quantitative alarms.

Normally, Alarm #2 is set to detect changes in the peak readings caused by the filter cleaning cycles.

Recall that as filters just begin to tear or become porous, the momentary puffs of particulate emissions

that normally occur just after a cleaning cycle will increase in peak height and duration (peak width).

Essentially the cleaning cycle amplifies the existence of small tears. Thus, setting an alarm to detect

changes in the peak emissions is often referred to as a Pre-Visible Alarm as it is the best, and most

reliable, approach to detecting emissions before become visible. When a sustained increase in the

baseline level occurs, particulate emissions will likely be visible and the filters should be changed

immediately. Where as, when only the peak emissions have increased, emission will likely not be

visible and there likely would be time to schedule changing the filters (i.e. early warning).

Technical assistance is available to provide suggestions in setting alarm levels.