5input sensor type, 6output function – Dwyer SCD User Manual

Page 3

3

5

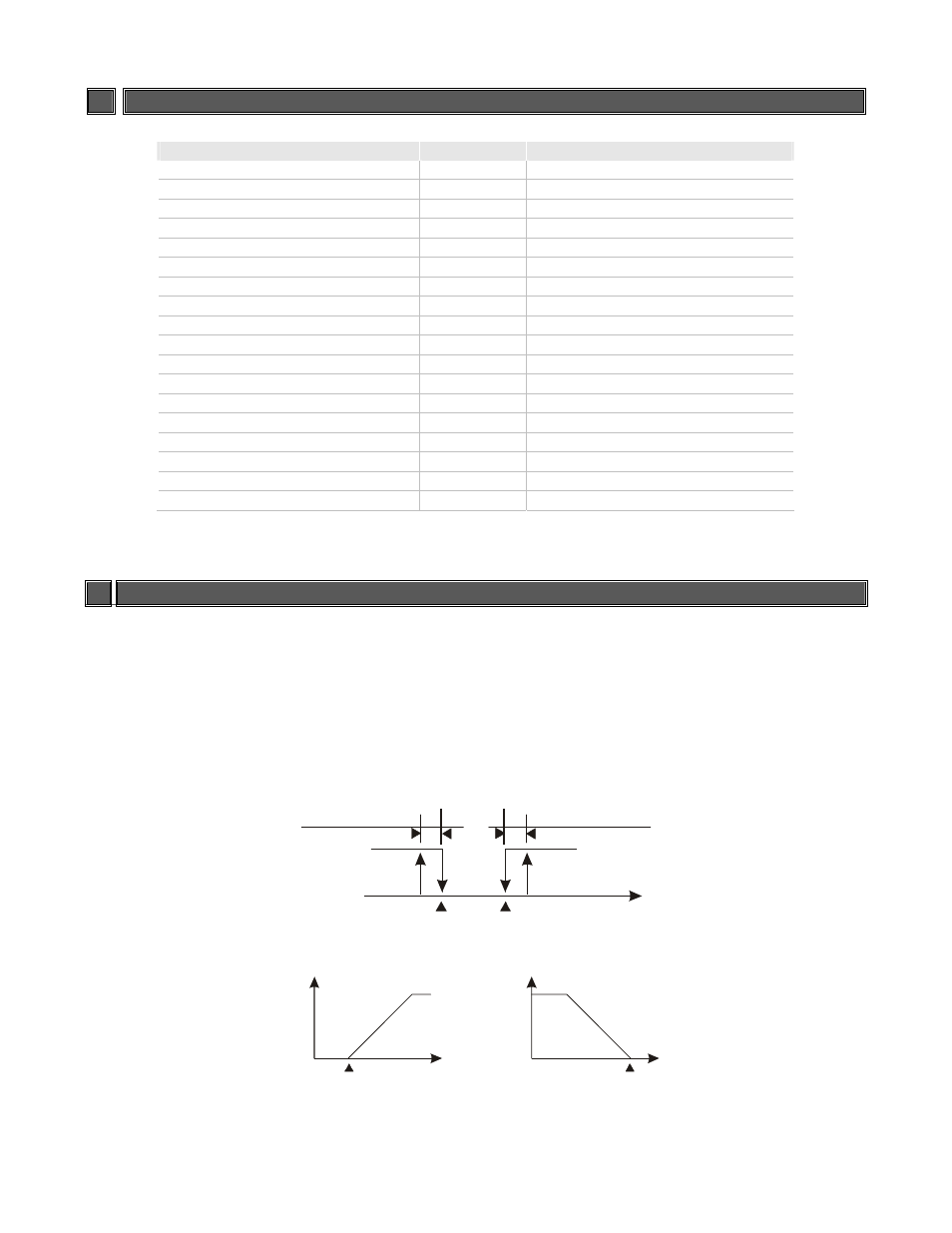

INPUT SENSOR TYPE

Input Selection for SCD series:

Input Sensor Type

Register Value

Available Range

0 ~ 50mV Linear Voltage Input

17

0 ~ 50mV

4 ~ 20mA Linear Current Input

16

4 ~ 20mA

0 ~ 20mA Linear Current Input

15

0 ~ 20mA

0 ~ 10V Linear Voltage Input

14

0 ~ 10V

0 ~ 5V Linear Voltage Input

13

0 ~ 5V

Platinum RTD (Pt100)

12

-200 ~ 600

o

C (-328 ~ 1112

o

F)

Platinum RTD (JPt100)

11

-20 ~ 400

o

C (-4 ~ 752

o

F)

Thermocouple TXK type

10

-200 ~ 800

o

C (-328 ~ 1472

o

F)

Thermocouple U type

9

-200 ~ 500

o

C (-328 ~ 932

o

F)

Thermocouple L type

8

-200 ~ 850

o

C (-328 ~ 1562

o

F)

Thermocouple B type

7

100 ~ 1800

o

C (212 ~ 3272

o

F)

Thermocouple S type

6

0 ~ 1700

o

C (32 ~ 3092

o

F)

Thermocouple R type

5

0 ~ 1700

o

C (32 ~ 3092

o

F)

Thermocouple N type

4

-200 ~ 1300

o

C (-328 ~ 2372

o

F)

Thermocouple E type

3

0 ~ 600

o

C (32 ~ 1112

o

F)

Thermocouple T type

2

-200 ~ 400

o

C (-328 ~ 752

o

F)

Thermocouple J type

1

-100 ~ 1200

o

C (-148 ~ 2192

o

F)

Thermocouple K type

0

-200 ~ 1300

o

C (-328 ~ 2372

o

F)

Note 1: An internal precision resistor for the current input is built-in, please refer to item 12, How To Set Up Current Input.

Note 2: Factory setting: PT100 input. It is adjustable for linear input and feedback ranges. The default range of input feedbadk is -999 ~ 9,999.

For example, when a 0 ~ 20mA analog input is selected as the input temperature sensor type, -999 indicates 0mA and 9,999 indicates 20mA.

If the user changes the input range to 0 ~ 2,000, 0 indicates 0mA and 2,000 indicates 20mA. One display scale equals to 0.01mA.

6

OUTPUT FUNCTION

Output control for SCD is selective: Control output (heating, cooling), Alarm output, or Retransmission output.

Control Output:

Temperature can individually be controlled by two groups of outputs: cooling (forward) or heating (reverse). When

Dual Loop output control is used, two output controls shall be designed for cooling (forward) or heating (reverse).

If two control outputs with the same direction are performed, only the 1

st

group of control period is valid.

Control methods: PID control, ON/OFF control, Manual control, and PID program control.

Single-output Control:

Heating Hysteresis

ON

OFF

PV

Figure1: ON-OFF control of single output

Cooling Hysteresis

Heating

Cooling

Set Point

Set Point

PV

100%

0

PV

100%

0

Output

Heating

Set Point

Output

Cooling

Set Point

Figure 2: PID Control,

forward (cooling) control

Figure 3: PID Control,

reverse (heating) control