Dwyer P72 User Manual

Page 3

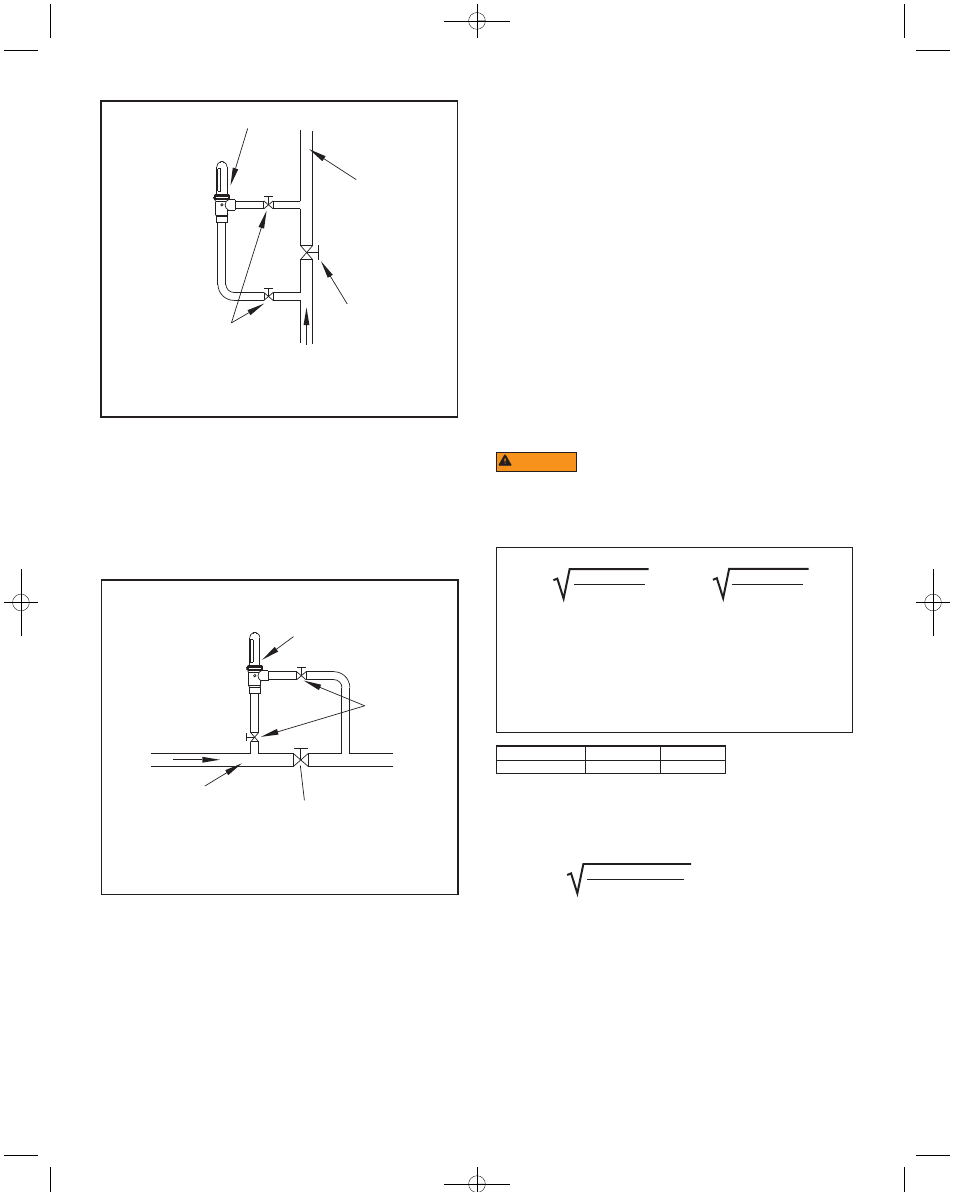

FLOWMETER

MAIN

PROCESS

LINE

BY-PASS

VALVE

FLOW

FIGURE 1: TYPICAL INSTALLATION-

VERTICAL LINE FOR LIQUID, GAS, OR VAPOR

SHUT-OFF

VALVES (2)

FIGURE 2: TYPICAL INSTALLATION-

HORIZONTAL LINE FOR LIQUID, GAS, OR VAPOR

SHUT-OFF

VALVES (2)

FLOWMETER

BY-PASS VALVE

FLOW

MAIN PROCESS LINE

Apply wrenches only on the flats or outer rims of the connection ports. Avoid over-

tightening, and do not use wrenches on other portions of the body or sight tube.

When solvent cementing in the vicinity of a meter with a polysulfone sight

tube, the tube should be removed until the cement dries and fumes clear.

SURGE CHAMBERS & ACCUMULATORS: Flowmeters are more accurate and

less likely to be damaged when the fluid flow is smooth. If the meter must be

installed on a line where reciprocating pumps or compressors causing pulsation

are used, surge chambers or accumulators are strongly suggested to damp the

shock wave.

SIGHT TUBE ROTATION: On P72-A indication models with polysulfone sight

tubes, grasp the tube firmly BY HAND near the body and twist until the scale faces

the desired direction. USE NO TOOLS!

On P72-B flowmeters, the magnet is encapsulated in the top of the float assembly

to seal it from the wetted system.

Figure 1

Figure 2

STARTUP

System flow should be started with the by-pass valve open and meter inlet and

outlet valves closed. After the system is operating, open the meter inlet valve

gradually to equalize internal pressure. Then slowly crack meter outlet valve and

wait for float to stabilize. Finally, slowly open the meter outlet and/or flow regulating

valve all the way and close the system by-pass valve. AVOID SUDDEN SURGES

THAT CAUSE THE METER FLOAT TO SLAM INTO THE TOP OF THE SIGHT

TUBE! Although not essential, the meter sight tube should be filled to a level above

the float on liquid systems. The snorkel tube (present in most standard models)

allows escape of entrapped gases except for a small pocket in the upper end which

helps cushion hydraulic shock. To assure proper filling and to flush any foreign

particles from the meter, operate the system at full flow briefly at startup.

READING FLOW

On transparent sight tube models, read flow directly from the scale as the number

nearest the top edge of the float indicator disk. For magnetically-linked models,

flow is read at the center of the ball indicator.

COMPENSATING FOR SYSTEM CHANGES

To find the correct flow reading for a system whose fluid conditions vary from those

for which the meter is scaled, use the conversion data below. The most practical

method of applying the formulae is to calculate a conversion factor for the new

system conditions, multiplying the scale reading by that factor. In the problems

below, ˝Qs˝ has been assigned a value of ˝1˝ to determine the conversion factor.

(The factory can provide special scales at additional cost for other fluids and/or

units.)

DO NOT OPERATE THE FLOWMETER ON A SYSTEM

EXCEEDING THE OPERATING LIMITS OF THE UNIT. WHEN CHANGING

OPERATING CONDITIONS, MAKE SURE THAT THE NEW SYSTEM

CONDITIONS ARE WITHIN THE FLOWMETER OPERATING LIMITS, AND ALL

WETTED MATERIALS ARE COMPATIBLE WITH THE FLUID.

CORRECTING READINGS FOR NEW LIQUID CONDITIONS

Qa = Qs

or Qa = Qs

Where:

Qa = Actual flow, GPM (or same units as scale).

Qs = Meter reading from scale, (scale units).

ps =

Specific gravity of calibration liquid related to water in

std. atmosphere at 70°F. being 1.00.

pa =

Specific gravity of metered liquid, same base.

ds =

Density of calibration liquid, lbs/ft3.

da =

Density of metered liquid, lbs/ft3.

pf =

Specific gravity of meter float.

df =

Density of the meter float per table.

ps (pf - pa)

pa (pf - ps)

ds (df - da)

da (df - ds)

Material

P72-A/P72-B

pf

VARIES*

df

VARIES*

*Average for these floats is f = 3.50, df = 217.8.

EXAMPLE: Using a standard brass meter scaled for water (s = 1.00), what is the

conversation factor for an oil with a specific gravity of 0.85?

1.00 (8.30 - 0.85)

0.85 (8.30 - 1.00)

Qa = 1.00 x

= 1.096

WARNING

F-P72:TEMPLATE 8/19/10 12:11 PM Page 3