Dwyer P72 User Manual

Page 2

INSTALLATION

PREPARATION: Series P72 Flowmeters are ready to install as-is, although the

sight tube may need repositioning so the scale is visible after installation. First,

remove the protective caps from the connection ports. ALSO, REMOVE THE

PLASTIC SHIPPING TUBING ABOVE THE INLET CAP IN THE METER CORE

TUBE! Check that the float moves freely within the core tube, and that no packing

materials are in the meter.

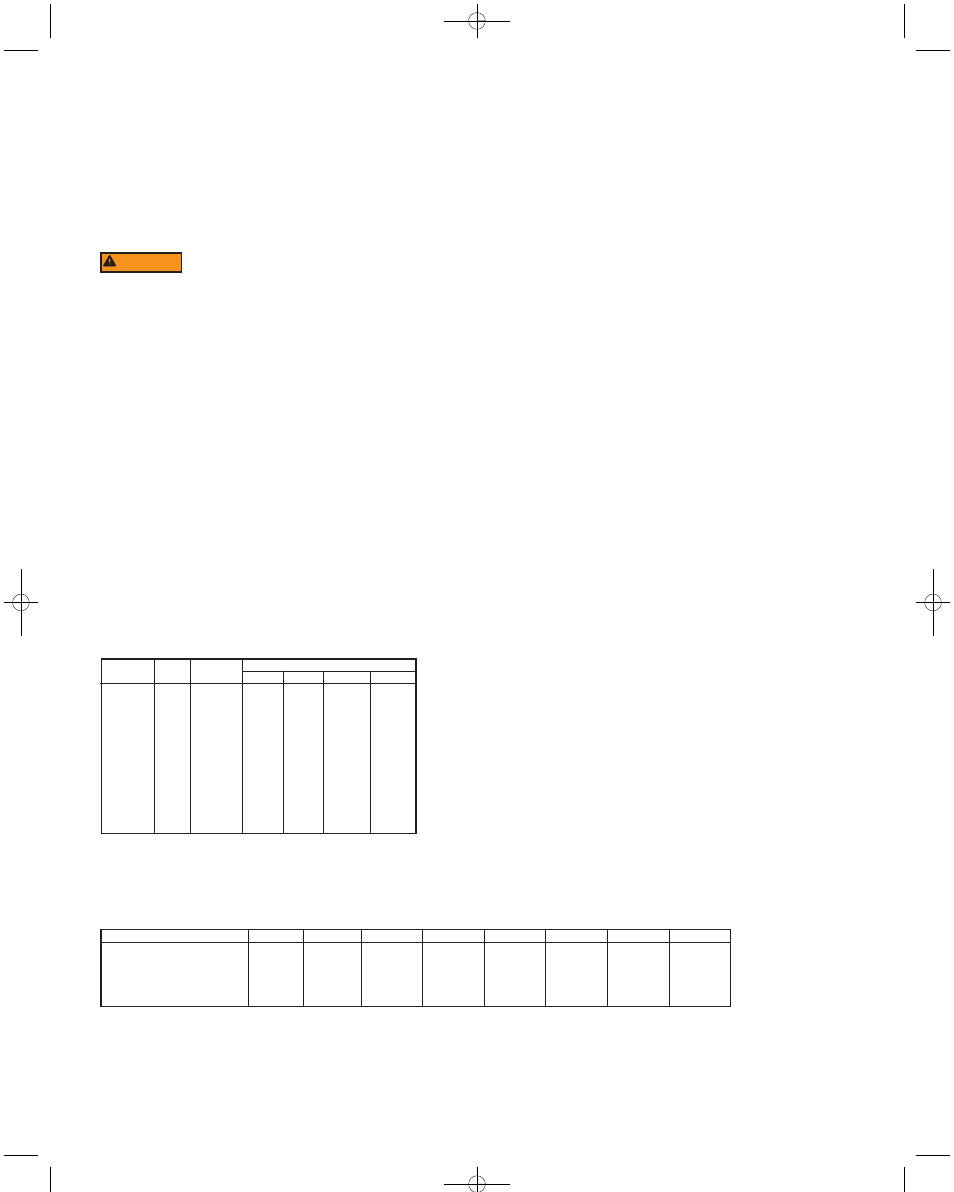

MAXIMUM FLOWS (WITHOUT EFFECTING ACCURACY)

FOR UNDERSIZED PIPES CONNECTED DIRECTLY TO FLOWMETER INLETS

PIPE NPS

1/4

3/8

1/2

3/4

1

1-1/4

1-1/2

2

2-1/2

3

4

6

DATA

(ID)

2

0.132

0.243

0.387

0.679

1.100

1.904

2.592

4.272

6.096

9.413

16.209

36.784

MAX. *

GPM LIQ.

1.72

2.98

4.74

8.31

13.47

23.32

31.74

52.29

74.56

115.2

198.4

450.0

ATMOS

0.864

1.59

2.53

4.44

7.20

12.5

17.0

28.0

39.9

61.6

106

241

50 PSIG

3.80

7.00

11.1

19.5

31.7

58.8

74.6

123

176

271

467

1059

100 PSIG

6.74

12.4

19.8

34.7

56.1

97.2

132

218

311

480

827

1878

MAX. SCFM AIR @ †

200 PSIG

12.6

23.2

37.2

64.9

105

182

248

408

582

804

1549

3514

* Data per Cameron Hydraulic Data. Based on 5 FPS max. liquid velocity having no effect on Series P72 flowmeters

accuracy if the inlet pipe is smaller than the meter connections.

† SCFM = 0.445 x (psig + 14.7) x (ID)2. Based on 20 FPS max. air velocity having no effect on Series P72 flowmeters

accuracy if the inlet pipe is smaller than the meter connections.

The Series P72 Flowmeters are heavy bodied meters for corrosives, gases, and

high purity fluids. These meters are designed specifically for demanding

applications. They are economically priced meters ideal for caustic solutions as well

as liquid chlorine, sodium hypochlorite and chlorine gas. The Series P72 Flowmeters

are suited for water treatment facilities that deal with these aggressive types of

gases and fluids. The P72-A is comprised of P72 and polysulfone, while the P72-B

has all P72 wetted components for maximum corrosion resistance. Units have a full-

scale accuracy of ±2% and can be disassembled quickly without the meter being

removed from the pipeline for easy cleaning. The Series P72 Flowmeters are

available with standard 3/4˝, 1-1/2˝, 3˝, and 4˝ flange connections. Optional NPT

connections are also available.

SAFETY PRECAUTIONS

Personnel safety should be considered before pressurizing and operating the

system. There are numerous possibilities for error in system operation and

maintenance as well as component installation. Because human eyes must

necessarily come into close proximity with the flowmeter to read it, it is

recommended that safety shielding be used with the meter along with safety

glasses. Another protective measure is to use a sheet of transparent, high-impact

material in a broad area in front of the meter. If hazardous, toxic, or flammable

fluids are being metered, recommended safeguards should include methods to

protect personnel from splash or rebound. A method of quick, safe removal of

dangerous fluids should also be included.

RECOMMENDED PIPING: Series P72 Flowmeters generally have no special

straight run or other piping requirements. Inlet piping should be the same size as

the meter connection. Some effect on meter accuracy may occur at high flow

velocities if inlet piping guidelines are violated. Please refer to the table below.

When installing on different size pipe, use standard pipe adapters and come into

the meter inlet with a nipple 8 diameters long of the same size for greatest

accuracy. Control valves should be mounted on the outlet side of the meter. The

use of a three valve manifold around the meter is suggested (per Figures 1 & 2) as

it allows uninterrupted process flow while the meter is being cleaned.

SPECIFICATIONS

Service: Compatible gases or liquids.

Wetted Materials:

P72-A: P72, polysulfone;

P72-B: P72.

Temperature Limits: See operating limits.

Pressure Limits: See operating limits.

Accuracy: ±2% of full scale.

Repeatability: ±1/2% of indicated flow rate.

Process Connections: 3/4˝, 1-1/2˝, 3˝ and 4˝ flange connection with optional

NPT connection available.

Weight: 3 lb (1.4 kg) for 3/4˝, 9 lb (4.1 kg) for 1-1/2˝, 14 lb (6.4 kg) for 3˝, and 18

lb (8.2 kg) for 4˝.

Body Size and Description

3/4˝ P72-NPT connection

1-1/2˝ P72-NPT connection

3/4˝ P72-Flange connection

1-1/2˝ P72-Flange connection

3˝ and 4˝ P72-Flange connection

70°F (21°C)

270 (19)

180 (12)

150 (10)

150 (10)

150 (10)

80°F (26°C)

270 (19)

180 (12)

150 (10)

150 (10)

150 (10)

100°F (37°C)

250 (17)

170 (11)

150 (10)

150 (10)

150 (10)

120°F (48°C)

200 (10)

145 (10)

135 (9)

135 (9)

135 (9)

140°F (60°C)

150 (10)

115 (8)

110 (8)

110 (8)

110 (8)

160°F (71°C)

130 (9)

75 (5)

90 (6)

90 (6)

90 (6)

180°F (82°C)

80 (6)

50 (3)

70 (5)

70 (5)

70 (5)

210°F (98°C)

50 (3)

30 (2)

40 (2)

40 (2)

40 (2)

OPERATING LIMITS FOR SERIES P72 FLOWMETERS

Maximum Non-Shock Working Pressure, PSIG @ °F (bar @ °C)

WARNING

F-P72:TEMPLATE 8/19/10 12:11 PM Page 2