Introduction, Installation – Dwyer TDS User Manual

Page 3

Step Three

INTRODUCTION

Technology:

The thermal dispersion flow switch measures liquid temperature to

determine changes in flow velocity. As fluid flows across the sensing

tips, the temperature is reduced proportionately as a function of the

flow rate. When a temperature or velocity shift reaches the user

defined set point, the switch changes state indicating the appropriate

flow condition (flow or no-flow).

Dwyer's sophisticated electronics convert the temperature shift into a

signal which indicates whether a flow or no-flow condition occurs.

Depending on how the sensor is wired, this signal may be wired for

normally open or normally closed circuits.

Dwyer's Thermal Dispersion flow switches have no moving parts to

clog or foul, making them suitable for a variety of applications,

including non-coating and non-scaling liquids. The TDS series

directly measure mass flow and can operate over a broad range of liq-

uids from 0.4 to 1.2 specific gravity, 1 to 200 cp.

Initialization Sequence for TDS series:

Powering up the TDS series is different in water and in air. When the

flow switch is powered up while submersed, the TDS series will

immediately indicate flow before switching to its correct state. When

the flow switch is powered up while in air, the TDS series will imme-

diately indicate no-flow before indicating its correct state. A time

delay may be used to eliminate this initialization sequence. Dwyer's

thermal dispersion relay controllers feature a 0 to 60 second time

delay for your convenience.

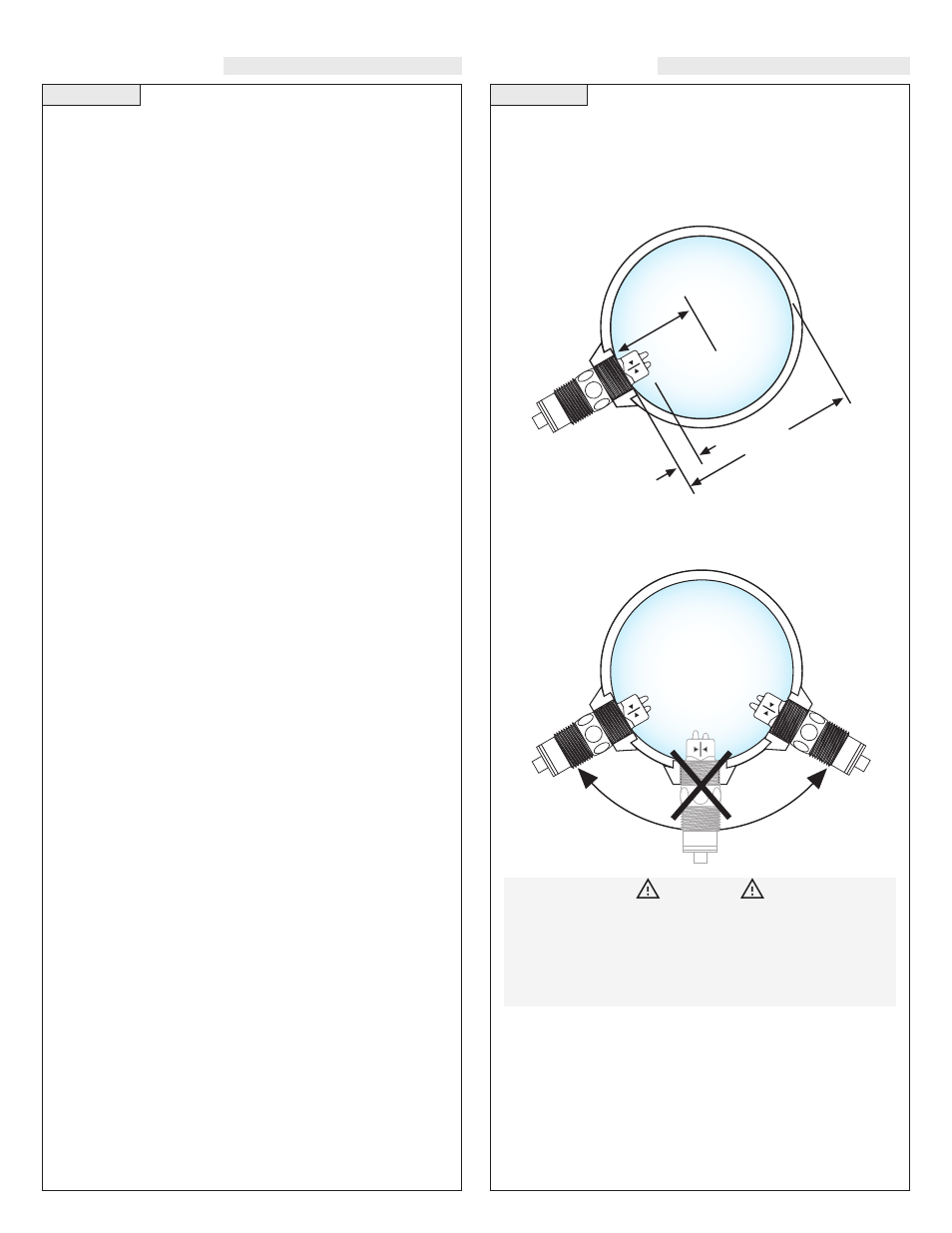

Step Four

INSTALLATION

When using any type of fitting, the orientation as well as the insertion

depth of the flow switch in the pipe is critical. See the diagram below

for the recommended orientation depth.

The TDS series flow switch when installed must always be in contact

with the liquid being measured. The flow switch feature a 3/4" NPT

threads which will allow it to be used with various types of fittings.

Be sure to check the insertion depth of the flow switch in the fitting

after it is installed. See the diagram below for the recommended inser-

tion depth.

WARNING

The flow switch tips have a thin plastic wall which may be dam-

aged if dropped or installed improperly.

The TDS series flow switch is designed for use in liquid. For best

results, avoid installing the TDS series where bubbles are present

or where the tips of the switch may be out of the liquid.

1/8 Pipe ID min.

Pipe ID

Acceptable

Insertion Range