Operation & maintenance, Flow rate (gpm) – Dwyer EFS2 User Manual

Page 6

Page 8

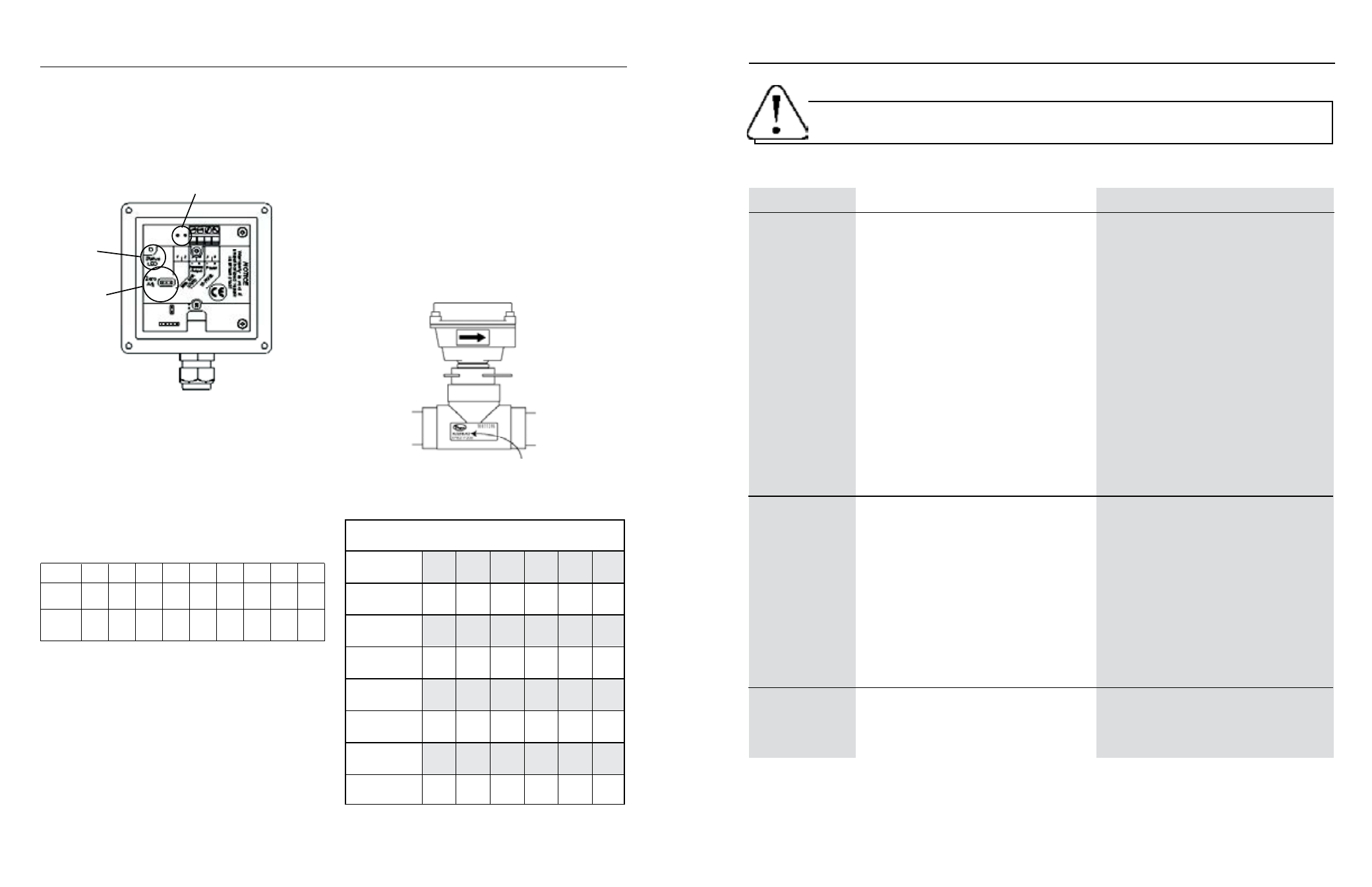

oPEration & maintEnancE

Zero adjustment.

When the EFS2 Series is powered up

and there is no flow, there should be no output pulses (or, if

connected to the RTI, flow rate should read “0”). If there are

pulses it may be necessary to adjust the flow meter under no-

flow conditions after it has been installed. This should only be

done if the indicated flow is low, near the lower cutoff.

To perform the adjustment, after determining that there is a

full pipe with no flow

, create a short between the two pins

marked “Zero Adjust”. Once the red LED light comes on for

approximately 50 seconds and then goes out, the zero adjust-

ment is completed.

minimum Flow.

As with any other flow sensor, there is a rate

below which the EFS2 Series sensor cannot read. Check the

flow rate table below for the minimum flow rate detectable by

the sensor for a given pipe size.

Presence of Flow indication.

To assist in troubleshooting,

the “Status LED” has two blinking modes in normal operation.

When there is no flow detectable by the meter (below minimum

threshold) the LED blinks every 8.0 seconds. When there is

detectable flow, the same indicator blinks every 3.0 seconds.

Filtering.

The software of the EFS2 Series sensor filters out

electrical noise and averages sudden variations in the flow to

smooth the output. It takes a matter of seconds for the flow

sensor to get up to full output when it is powered up or when

flow begins.

calibration (“K-factor”).

The K-factor represents the actual

number of pulses per gallon the meter produces during a flow

test. This number can be entered into your electronic control

to make it read properly. If the EFS2 Series meter is ordered

with a tee fitting, it is factory-calibrated in the fitting and the

K-factor is indicated on the side of the fitting (see diagram).

Find your K-Factor Here

Page 9

Zero

adjust

Pins

Electrode coating.

Grease or other adhering, non-conductive

materials can stop flow detection if the electrodes become

heavily coated. To clean the electrodes, remove the sensor

from the pipe and gently scrub the electrodes (three silver

bumps) on the reading face of the flow sensor. A mild soap

(dishwashing liquid for example) can be used to aid the

cleaning process.

If the EFS2 Series meter is ordered with a saddle or weldolet

fitting

, find your K-factor in the chart below.

3” 4” 6” 8”

10”

12”

K-FactorS SaDDlES & WElDolEtS

Status

lED

PVc/Steel

Sch. 40

PVc/Steel

Sch. 80

Stainless

Steel (10S)

Stainless

Steel (40S)

copper tubing

(type l)

copper tubing

(type K)

brass Pipe

Duct. iron

(class 52)

70.397

78.748

62.385

70.397

76.371

78.371

70.672

57.376

40.985

45.360

36.626

40.985

43.552

44.638

41.517

37.320

18.130

20.084

16.510

18.130

19.513

20.223

17.778

16.915

6.674

7.322

6.173

6.674

7.230

7.500

6.674

6.197

10.497

11.495

9.642

10.497

11.201

11.622

10.445

9.503

notE:

K-factors are in Pulses/gallon. For Pulses/Liter, divide

by 3.785.

4.709

5.184

4.373

4.661

5.016

5.239

4.661

4.325

1” 1-1/2” 2” 3” 4” 6” 8” 10” 12”

• Min

.7

1.5

2.7

6

11

25

44

69

99

@ 0.28 ft/sec

• Max

49

110

196

440

783 1760 3130 4900 7050

@ 20 ft/sec

FloW ratE (gPm)

Nominal

Pipe Size

reverse output option

Problem

Probable cause

try...

Check plumbing

Check the presence of Flow with the use of the

Flow Indication LED (see pg. 8)

Connect to earth ground

Check for proper electrical wiring

Check for power across power

input terminals

Note flow direction arrow,

reverse direction of meter

Reverse connections

Change output connections

Select another flow meter

Check for proper ground

Check for proper electrical wiring

Select another flow meter

Check for full pipe or install meter in the verti-

cal position

Check for ten diameters upstream AND five

diameters downstream

Install chemical injection line downstream of

magmeter (or far enough upstream to allow

complete mixing of fluids before meter)

Pipe not full

Below minimum flow cutoff

Unit not grounded

Excessive electrical noise

No power

Flow reversed

Power reversed

Output connections reversed

Fluid conductivity <20 microSiemens/cm

Missing or incorrect ground wire

Excessive electrical noise

Fluid conductivity <20 microSiemens/cm

Empty pipe

Not enough straight pipe

Rapidly changing conductivity (in chemical

injection or fertigation applications)

caution & troublESHooting

troublESHooting

caution:

The electronics of the EFS2 Series meters are not field-repairable.

Warranty is void if unauthorized repair is attempted

No pulse output

Output pulses

incorrect

Jumpy reading