Dwyer EFS2 User Manual

Page 4

metallic Pipe

Earth

ground

grounding clamp

inStallation

Page 4

Page 5

ElEctrical connEctionS

grounDing Diagram

general Electrical guidelines:

• Whenever possible avoid running control cables in

the same conduit with or bundled with AC power.

• Using shielded cable, be sure to connect shield to

ground at power supply end of the cable.

• Avoid routing flow sensor cables in close proximity to

a variable frequency drive.

• Recommended power and output wiring is shielded

twisted pair 18 to 22 AWG control cable.

• Recommended voltage is 12 to 24 Vdc. Note that

unregulated power supplies can vary from nameplate

voltage by a considerable amount, especially with AC

line voltage fluctuation. Therefore 24V power supplies

must be regulated.

See the Connections diagrams on tpages 6 & 7 for the ap-

propriate terminals.

Power:

A 12 to 24 Vdc power supply capable of at least 250

mA current output is needed.

Forward Flow output:

This open-collector isolated output

does not supply power. This pulse is generated in the forward

flow direction on the standard unit. (Reverse flow output is

available as an option).

note:

This output is limited to 6 mA at 30 Vdc maximum.

reverse Flow output:

Reverse flow output is available as

an option. This open-collector isolated output does not supply

power. It functions like a polarity-sensitive switch closure.

note:

This output is limited to 6 mA at 30 Vdc maximum.

PlacE FErritE bEaD HErE

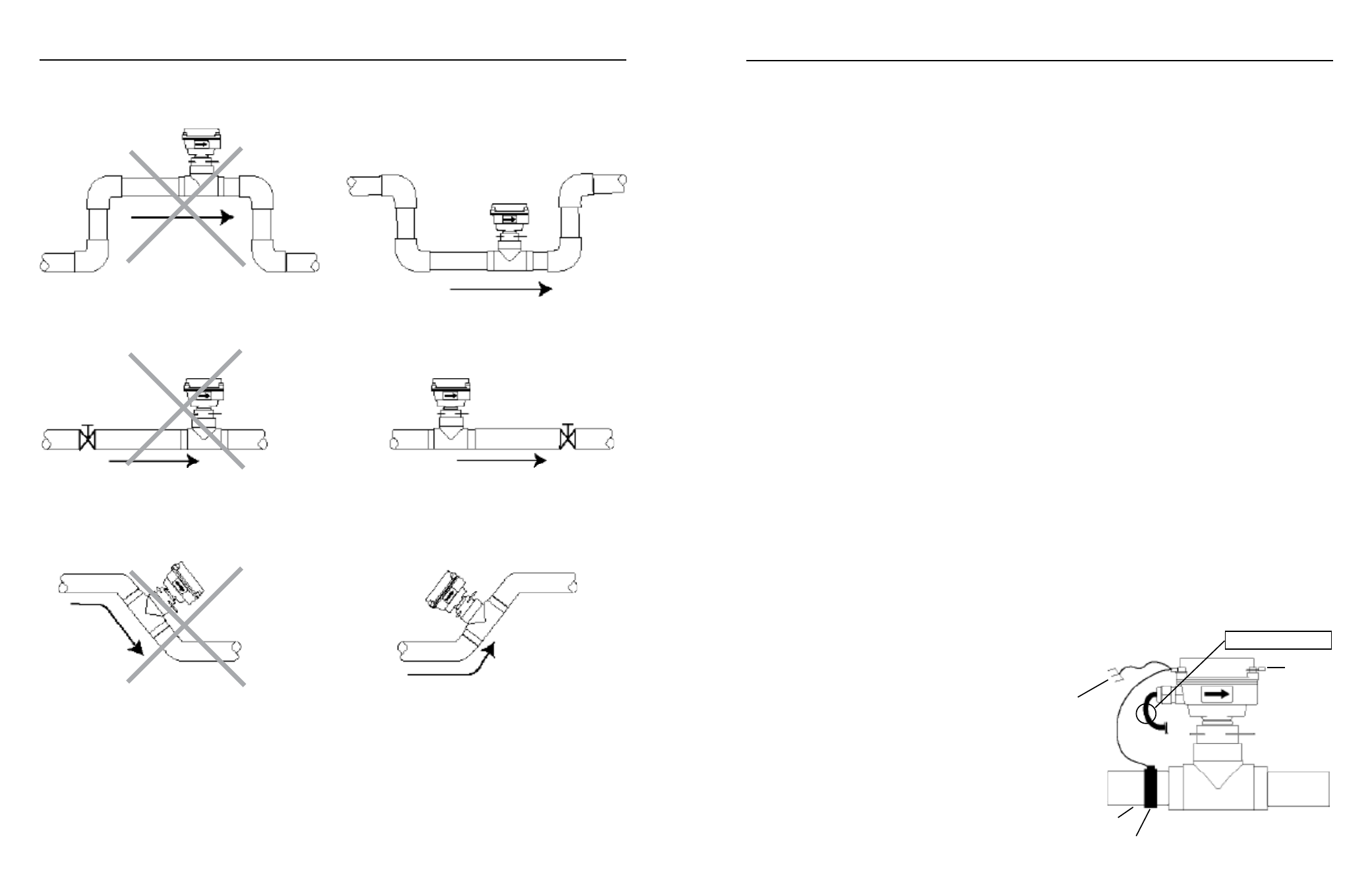

Full PiPE rEcommEnDationS

Possible Problem:

Allows air pockets to form at sensor

better installation:

Ensures full pipe

Possible Problem:

Post-valve cavitation can create air pocket

better installation:

Keeps pipe full at sensor

Possible Problem:

Air can be trapped

better installation:

Allows air to bleed off

Housing

Screw

grounding guidelines:

For best results, use a good quality earth ground, such as

metallic water piping or a driven ground, to ensure a good

connection to earth ground and good noise suppression.

For metallic Pipe:

For optimum connection, clamp wire to the

piping a short distance to one side of the flow sensor using

an electrical grounding clamp. Connect the wire to the earth

ground and to one of the housing screws.

For non-metallic Pipe:

Connect a wire from the housing screws

to a good earth ground, such as metalic water piping or a rod

driven into the ground, as shown in the “Grounding Diagram”

below.

Series EFS2 & IEFS meters are usually unaffected by moderate

levels of electrical noise. In some applications performance

may be improved by taking the following steps:

• Use shielded twisted pair cable (Belden 8723 or

equivalent above ground or Alpha 35482 or

equivalent burial).

• Clamp a ferrite bead (Steward 28A2029-OAO or

equivalent) on meter signal/power wire within 3/4”

of the meter strain relief (tape or tie wrap in place

if necessary). See diagram below.

• IMPORTANT - Connect the cable shield ground

wire to ground, ONLY at power supply end of cable.