Dwyer instruments, inc – Dwyer 641 User Manual

Page 4

Span Setting

The Series 641 AVT has been calibrated for standard sea

level conditions. As a mass flow device it will always read

the air velocity for standard conditions. Density changes due

to barometric or absolute pressure are not corrected auto-

matically. The span setting allows correction for altitude or

other static pressure conditions that affect the density of the

process air. This parameter allows for a ±50% adjustment in

the span value.

To make the span adjustment you will need to know either

the absolute static pressure or the corrected velocity of the

process air. Set the air velocity to a known value, ideally

about 3/4 of the full-scale range value. Press SELECT until

the SPAN LED indicator is illuminated then press ENTER.

The SPAN LED will begin to blink. Adjust the control for the

desired velocity then press and hold the ENTER button until

all of the LED’s flash, indicating the new value was saved. If

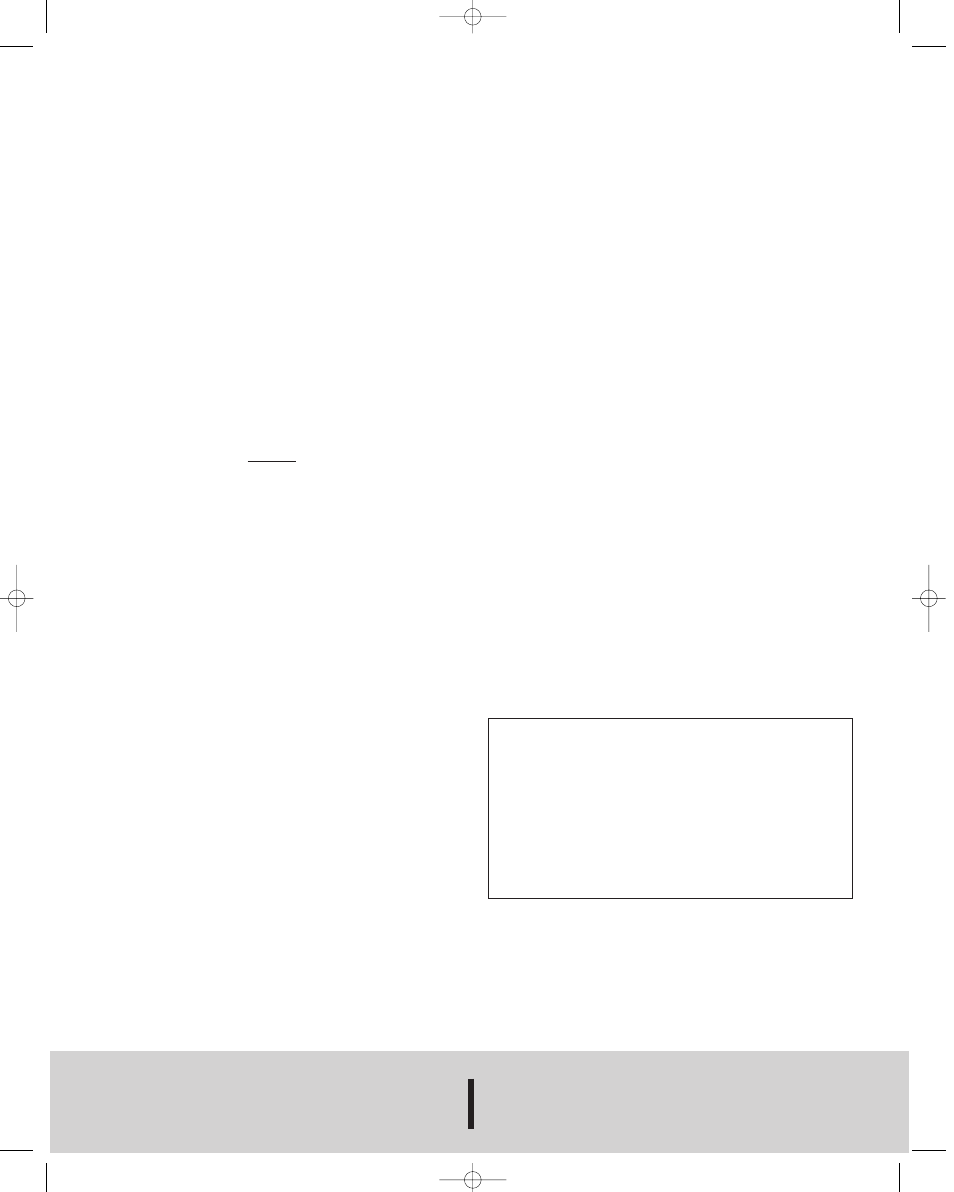

you know the absolute static pressure you can compute the

corrected velocity using the following equation:

Where:

P0 is the standard pressure of 29.9 in. Hg. or 760 mm Hg.

PA is the absolute pressure reading

Vrdg is the indicated velocity

Vcor is the corrected velocity

4 mA Setting

To make this setting you will need a milliammeter connect-

ed in the current loop. It is not required to use a known air

flow velocity to make this calibration setting. The calibration

settings of the velocity and the mA outputs are independent

of each other. Press SELECT until the 4 mA LED indicator is

illuminated then press ENTER. The milliammeter will now

read approximately 4.0 mA. Adjust the control for a 4.0 mA

reading on the milliammeter. Press and hold ENTER to save

the new setting. Pressing SELECT before pressing ENTER

will restore the previous calibration value.

20 mA Setting

It is not required to use a known air flow velocity to make

this calibration setting. The calibration settings of the veloc-

ity and the mA outputs are independent of each other. Press

SELECT until the 20-mA LED indicator is illuminated. Press

ENTER to begin adjustment of the 20-mA set point. The 20

mA LED will now be blinking. Adjust the control until the mil-

liammeter reads 20.0 mA. Press and hold ENTER to save

the new setting. Pressing SELECT before pressing ENTER

will restore the previous calibration value.

Restoring Factory Default Settings

The 4 mA, 20 mA, and Range settings override factory

default values. To restore these to the factory default set-

tings, start with the unit in the RUN mode. Press and hold

the ENTER button. The RUN LED indicator will begin to

blink. After about 2.5 seconds all LED indicators will flash

indicating the factory settings have been restored. Range

and Filter settings are not affected by this operation. If you

are unsure whether any have been altered, press the

SELECT button six times to sequence through all settings.

When you return to the RUN mode, the RUN LED indicator

will blink several times if either the 4 mA, 20 mA, or span

settings have been changed. The RUN LED will otherwise

remain on.

MAINTENANCE

In general the Series 641 AVT should require very little main-

tenance. In some installations dust may accumulate on the

sensor over time. This can be removed by carefully brush-

ing the probe with a small camel hairbrush. If too much force

is applied during cleaning, the sensor of the Series 641 AVT

may be damaged. Therefore, a trained technician should

perform the cleaning operation. A jet of air may also dis-

lodge the accumulated buildup however, again, the sensor

is delicate and this operation should be done carefully with

clean regulated air. Using a shop air supply may exert

enough force to damage the sensor. Most air supplies of

this sort will also contain water or oil that could damage the

sensor. Technical grade denatured or isopropyl alcohol may

be used where the dust accumulation does not respond to

brushing. Do not use water. Always disconnect the power

when performing a cleaning operation.

Aside from field calibrations for span, 4 mA and 20 mA set-

ting as described above, the Series 641 cannot be fully fac-

tory calibrated in the field. Because of specialized comput-

er instrumentation required, these units must be returned to

Dwyer Instruments for factory calibration. Contact customer

service to receive a return goods authorization number

before shipping.

CE

The following standards were used for CE approval:

IEC 61000-4-2: 2001

IEC 61000-4-3: 2002

IEC 61000-4-4: 1995

IEC 61000-4-5: 2001

IEC 61000-4-6: 2003

IEC 55011: 1998

IEC 61326: 2002

89/336/EEC EMC Directive

©Copyright 2004 Dwyer Instruments, Inc.

Printed in U.S.A. 11/04

FR# 443205-10 Rev. 1

Page 4

P

o

P

A

V

rdg

V

cor

=

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000

www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A.

Fax: 219/872-9057

e-mail: [email protected]

641-CE bulletin 11/9/04 3:49 PM Page 4