Dwyer MS2-B User Manual

Page 4

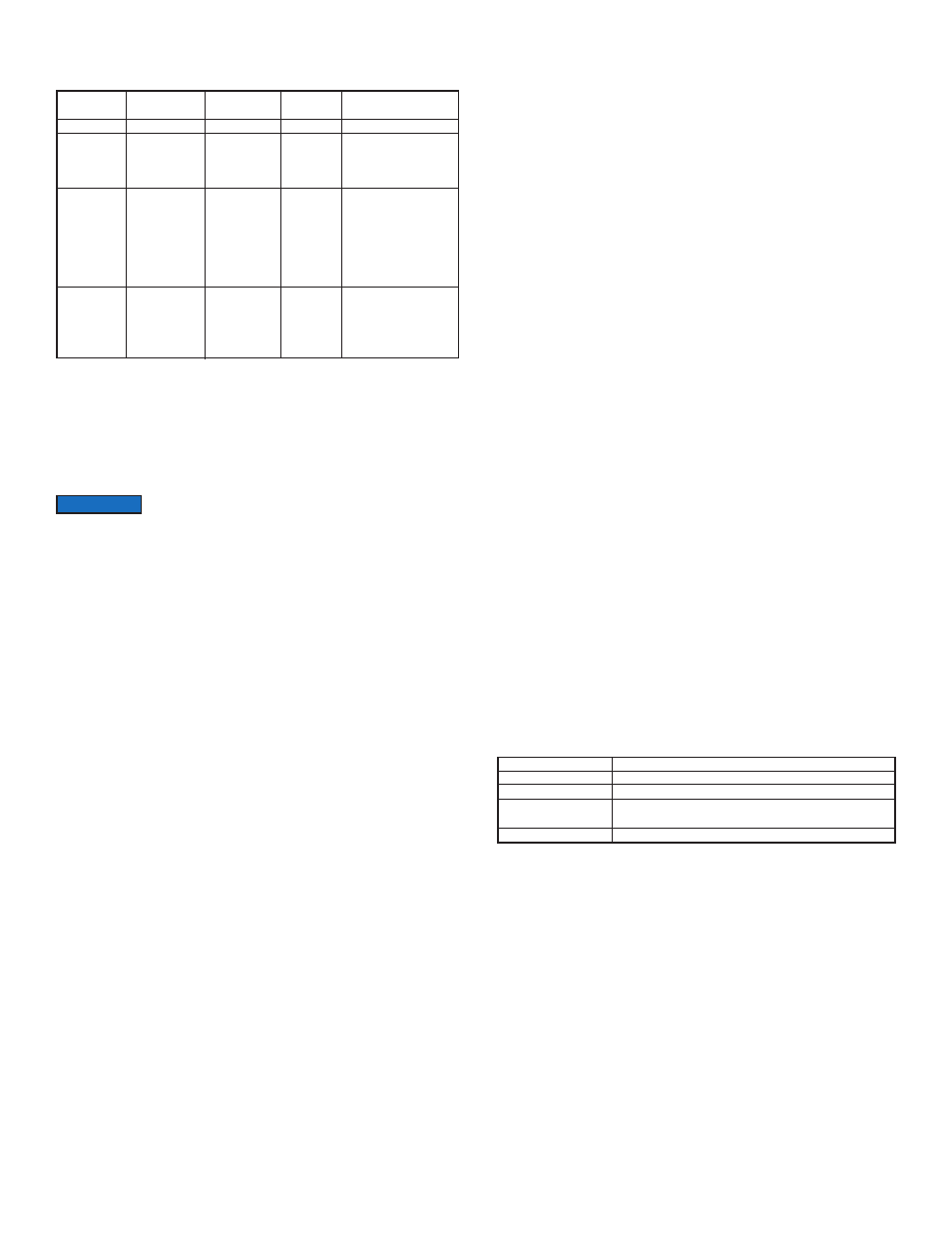

BACnet Communication Protocol Object Overview

The device supports the following objects

Device Information

The default device object identifier is 607xxx, where xxx is replaced by the MS/TP

MAC address set by the left DIP switch SW1. The object identifier value will change

as the MS/TP MAC address changes. However, if a specific object identifier is

written via BACnet Communication Protocol, then that value is stored and changes

to the MS/TP MAC address will no longer affect the object identifier. See Appendix

II for the device object property table.

Accessing the Measurements

The analog input object AI1 through AI4 are for viewing the pressure measurement

in the desired engineering units. The object property tables for these analog input

objects can be found in Appendix III.

Analog value object AV1 through AV4 are for viewing the Air Velocity or Air Flow

calculated values in the desired engineering units. The object property tables for

the analog value objects can be found in Appendix IV.

Setting the K factor and Area

There is an additional analog object value (AV5) for setting the K factor used to

calculate the velocity and air flow. The present value would be the value of the K

factor and can be set from 0 to 9.999.

For flow measurements, the area will also have to be set using analog value object

AV6. The present value would be the area in square feet. The area can be set from

0.01 to 999.99 square feet.

The object property tables for the analog value objects can be found in Appendix

IV.

From the factory, a K factor and the area are preset to be 1.000. If at any time the

user would like to default back to these values, they can disable the programmed

K factor and area mentioned above using the binary value object (BV1). The

present value of this object determines how the velocity and flow will be calculated.

When this value is ACTIVE (1), the default values for the K factor and area will be

used. If the value is INACTIVE (0), the presently set values for the K factor and area

will be used. The object property tables for the binary value objects can be found

in Appendix V.

Zero Calibration

Zero calibration can be done either with the push buttons or using BACnet

communications. Both pressure ports should either be vented to atmospheric

pressure or should have no pressure applied. When using BACnet

communications, the binary value object (BV2) will be used to signal the transmitter

to zero the reading. The present value of this object will be set to ACTIVE (1) to

initiate the re-calibration of the zero point of the sensor. The zero function will only

work if the current pressure is within ±2% of the span pressure of the previous zero.

If the current pressure is outside of this valid band, the zero function will fail and the

present value will be changed to INACTIVE (0). The zero function takes at most 10

seconds to complete. If after this time the present value remains ACTIVE (1), then

the command was executed successfully. The object property tables for the binary

value objects can be found in Appendix V.

Span Calibration

In order to adjust the span calibration, apply pressure to the ports of the transmitter

that is associated with the maximum end of the transmitter range. The binary value

object (BV3) will be used to signal the transmitter to adjust span. The present value

will be set to ACTIVE (1) to initiate the span calibration. The span calibration can

be adjusted only after setting the zero adjustment. It must be completed within 5

minutes of the last zero calibration. The span calibration command will fail until the

zero calibration is completed and the present value will be returned to INACTIVE

(0). The span function takes at most 10 seconds to complete. If after this time, the

present value remains ACTIVE (1), then the command was executed successfully.

The object property tables for the binary value objects can be found in Appendix V.

Reset factory Defaults

Present values for the zero, span, K factor, area, and Use Default K Factor can be

restored to the factory settings using the binary value object (BV4). The present

value will be set to ACTIVE (1) to initiate the factory default procedure. The factory

default takes at most 10 seconds to complete. If after this time, the present value

remains ACTIVE (1), then the command was executed successfully. The object

property tables for the binary value objects can be found in Appendix V.

BACnet Communication Protocol Services

Device Communication Control Service (DM-DCC-B)

This device supports the Device Communication Control Service BIBB. The

optional time duration in minutes is also supported. This device is configured with

a password that must be provided to successfully execute this command. The

password is “Dwyer”.

Reinitialize Device Service (DM-RD-B)

This device supports the Reinitialize Device Service BIBB. The supported device

states are COLDSTART and WARMSTART. All other states return error. This

device is configured with a password that must be provided to successfully execute

this command. The password is “Dwyer”.

LeD Status

The device provides three LEDs to indicate status and activity. The LEDs are

located to the right of the terminal block and are arranged from left to right as green,

yellow, and red. The green LED indicates communication with the pressure sensor.

This LED will flash very quickly most of the time, even without requests from the

BACnet Communication Protocol interface. The yellow LED indicates BACnet

Communication Protocol MS/TP communication addressed to this specific device.

The frequency and duration of this LED depends on the baud rate and size of

request sent. The red LED indicates error states by flashing specific error codes

periodically.

MAINTeNANCe/RePAIR

Upon final installation of the Series MS2 Differential Pressure Transmitter, no

routine maintenance is required. The Series MS2 is not field serviceable and it is

not possible to repair the unit. Field repair should not be attempted and may void

warranty.

WARRANTY/ReTURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website. Contact

customer service to receive a Return Goods Authorization number before shipping

the product back for repair. Be sure to include a brief description of the problem

plus any additional application notes.

Dynamically

Creatable

No

No

No

No

Object

Type

Device

Analog Input

Analog Value

Binary Value

Dynamically

Deletable

No

No

No

No

Object

Identifier

607xxx

Al1

Al2

Al3

Al4

AV1

AV2

AV3

AV4

AV5

AV6

AV7

BV1

BV2

BV3

BV4

Object

Name

MS2 Pressure

Pressure inWC

Pressure Pascals

Pressure Kilo-Pascals

Pressure mmWC

Velocity FPM

Velocity MPS

Flow CFM

Flow CMH

Velocity K Value

Flow Area SqFt

Sensor Present

Use Default K Value

Zero

Span

Restore Factory

Pressure Values

Number of flashes

Solid On (not flashing)

1

2

3

error Description

Invalid Factory Configuration

Invalid BACnet Communication Protocol MS/TP Address

Auto Baud Configuration in progress, unit may not

respond to requests

Communication with pressure sensor failed

Changes to Max Master and Max Info frames require a power

cycle/reset to take effect.

NOTICe