Dwyer A3000 User Manual

Dwyer instruments, inc, Series a3000 photohelic, Differential pressure switch/gage

INSTALLATION

1. Location: Select a clean, dry, vibration-free location where

ambient temperatures will be between 20 and 120°F (-6.67 and

48.9°C). Tubing supplying pressure to the instrument can be prac-

tically any length but long runs will increase response time slightly.

2. Position: The PHOTOHELIC

®

Switch/Gage is factory calibrated

for use with scale in a vertical plane. Operation at other angles may

affect accuracy and/or require zero adjustment. Most models can

be specially calibrated at the factory for other positions if specified

at time of ordering. Ranges below 1˝ W.C. must be used only with

scale vertical.

3. Mounting: The PHOTOHELIC

®

Switch/Gage is normally mount-

ed before making electrical connections. The electrical enclosure

is removable at any time regardless of mounting method.

(A) Panel Mounting: Normal mounting is flush or through panel

as shown in Fig. B. Allow 4-

3

/

8

˝ (111.13 mm) clearance behind the

unit for removal of electrical enclosure. Make a 4-13/16˝ (122.24

mm) diameter hole in panel. Insert the PHOTOHELIC

®

Switch/Gage unit from front of panel and slip mounting ring over

case from behind with stepped side facing rear. Fit the snap ring

into narrow groove at back edge of the bezel. Thread four 6-32 x

1-1/4˝ mounting screws into tapped holes in mounting ring and

seat it against snap ring. Tighten screws against back of panel.

See Fig. B.

Series A3000 Photohelic

®

Differential Pressure Switch/Gage

Specifications - Installation and Operating Instructions

Bulletin B-33-A

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000

www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A.

Fax: 219/872-9057

e-mail: [email protected]

The Series A3000 PHOTOHELIC

®

Switch/Gage is a versatile

2-in-1 instrument combining a time-proven Magnehelic

®

differen-

tial pressure gage with low/high pressure switches. It is designed

to measure and control positive, negative or differential pressure of

air or other non-combustible, non-corrosive gases. Gage reading

is unaffected by switch operation. Switch set points are easily

adjusted with knobs located on gage face. Applied pressure and

switch set points are fully visible at all times. Deadband is one

pointer width, less than 1% of full scale. Each set point controls a

DPDT relay and both relays can be interlocked to provide variable

deadband control.

SPECIFICATIONS

GAGE SPECIFICATIONS

Service: Air and non-combustible, compatible gases.

Wetted Materials: Consult factory.

Accuracy: ±2% of full scale at 70°F (21.1°C). ±3% on -0 and

±4% on -00 models.

Pressure Limits: -20" Hg. to 25 psig (-0.677 to 1.72 bar). MP

option; 35 psig (2.41 bar), HP option; 80 psig (5.52 bar). 36003S

– 36010S; 150 psig (10.34 bar). 36020S and higher;1.2 x full

scale pressure.

Temperature Limits: 20 to 120°F.

(-6.67 to 48.9°C) Low temperature option available.

Process Connections: 1/8˝ female NPT.

Size: 4˝ (101.6 mm) dial face, 5˝ (127 mm) O.D. x 8-1/4˝ (209.55

mm).

Weight: 4 lb (1.81 kg).

SWITCH SPECIFICATIONS

Switch Type: Each setpoint has 2 Form C relays (DPDT).

Repeatability: ±1% of full scale.

Electrical Rating: 10A @ 28 VDC, 10A @ 120, 240 VAC.

Electrical Connections: Screw terminals. Use 167°F (75°C)

copper conductors only.

Power Requirements: 120 VAC, 50/60 Hz; 240 VAC & 24 VAC

Power optional.

Mounting Orientation: Diaphragm in vertical position. Consult

factory for other position orientations.

Set Point Adjustment: Adjustable knobs on face.

Agency Approvals: UL: File No. E38121, Vol. 1, Sec. 4; CSA:

File No. LR22541-34; CE: EN 61000-6-2: 1999, EN 6100-3-2:

2000, EN 61000-3-3: 2000.

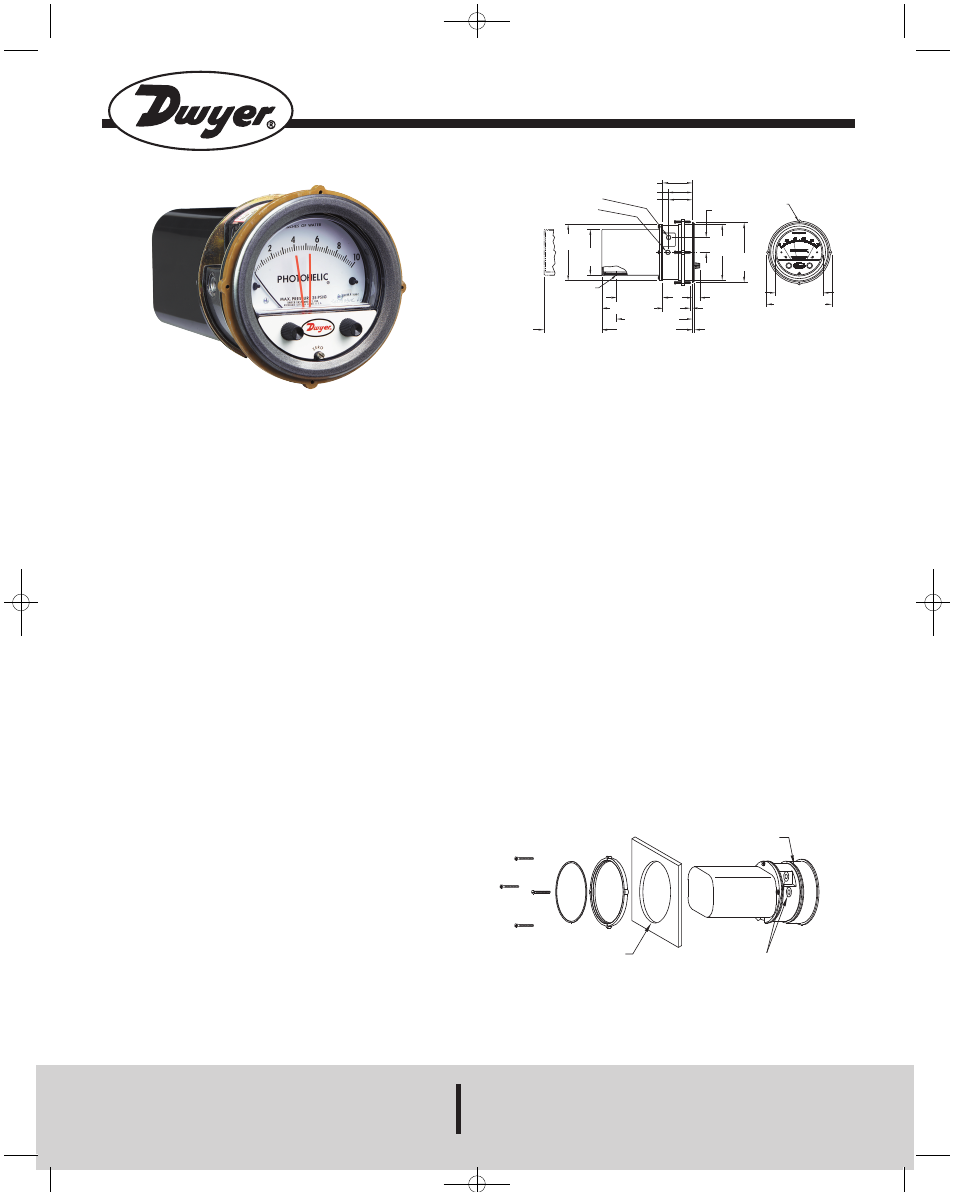

Ø4-13/16 [122.24]

HOLE REQUIRED FOR

PANEL MOUNTING

1/2 NPT(M) PRESSURE CONNECTION.

SINGLE HIGH PRESSURE CONNECTION

FOR SERIES 36000S MODELS.

SNAP RING GROOVE

Fig. A

Fig. B

NOTE: Detailed dimension drawings are available from our Customer Service

Dept. for PHOTOHELIC

®

switch/gages as installed in two optional enclosures.

For weatherproof housing, request no. 13-700132-00. /For explosion-proof

housing, request no. 13-700113-01.

2-1/2 [63.50]

2-1/16 [52.39]

2 [50.80]

1-1/4

[31.75]

(4) 6-32 HOLES

EQUALLY SPACED ON

A 5-1/8 [130.18] B.C.

Ш4-47/64

[120.25]

Ш5

[127.00]

Ш4 [101.60]

FACE

5-1/2 [139.70]

O.D.

MOUNTING

RING

5/8 [15.88]

5/8 [15.88] PANEL

MAX

3/16 [4.76]

3-7/8 [98.43]

5-1/8 [130.18]

6-3/8 [161.93]

(7-5/8 [193.68])

4-3/8 [111.13]

HOUSING REMOVAL

3/4 CONDUIT

CONNECTION

Ø4-3/4

[120.65]

3-7/8 SQ

[98.43]

1/8 FEMALE NPT HIGH

PRESSURE CONNECTION

1/8 FEMALE NPT LOW

PRESSURE CONNECTION

B-33-A:B-33-A 8/14/09 3:02 PM Page 1