Dwyer 43000 User Manual

Page 4

6. Dual Set-Point Manual Reset: Circuit Style HH may also be used for manual reset

applications where it is desired to have maintained contact on either relay following

pressure increase above its set-point. Load or signal connections are made to the

appropriate terminals in Sections A and D (as in paragraph 5 above). Connect

terminals in Sections B and C through normally closed switches or push buttons as

shown in Figure 8. Use of “dry-circuit” type switches such as Dwyer Part No. A-601

with paladium, gold, etc. or rotary wiping action type contacts is recommended.

Make external ground connections as required and connect power to Section E for

the control unit.

Circuit Style LL is used for manual reset applications which require that contact be

maintained following pressure decrease below the set-point. Load connections are

made to the appropriate terminals in Sections A and D. A normally open type

manual reset switch such as Dwyer Part No. A-601 is connected to the terminals

in Sections B and C. The circuit must be “armed” by momentarily closing the switch

while the black pointer is to the right of the set-point. From that point on, the circuit

will latch on pressure decrease below the set-point and remain latched on pressure

increase until manually reset with the optional switch.

7. Dual Set-Point Automatic and Manual Reset Combinations: Circuit Style HH

may be used with either set-point wired and operating as in paragraph 5 above and

other set-point wired and operating as in paragraph 6.

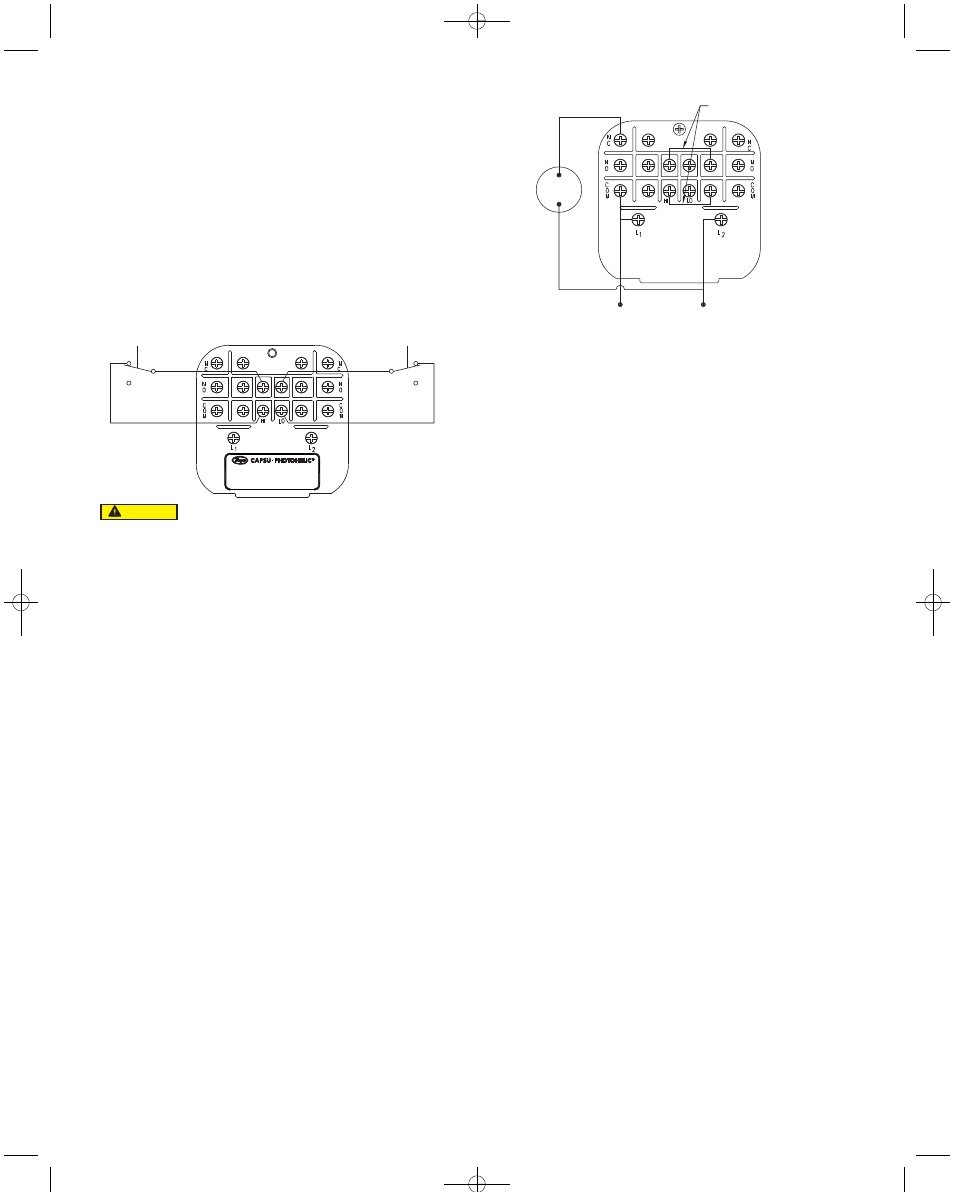

8. High Low Limit Control – Dual Set-Point: Circuit Style HH may be used to control

fans, dampers, pumps, etc., between the set-points of a Capsu-Photohelic

®

.

To accomplish this, use one set-point relay to reset the other as shown in the wiring

diagram Figure 9. In this typical application, the load (for instance a fan) would be

connected to the N.C. contacts for the right set-point relay, Section A (Figure 6). On

pressure rise to the right set-point, its relay would pull in and hold even though

pressure might then fall below that set-point. If the pressure continued to fall to the

left set-point, its relay would automatically be DE-ENERGIZED, return to its normal

position and in so doing, open the holding coil circuit from Section B (Figure 6). The

right set-point relay would thus be reset and the cycle could repeat.

9. Dual Set-Point Special Purpose Circuits: Circuit Style LL may be used where

manual reset following maintained contact on pressure decrease to either set-point

is desired. Circuit Styles HL and LH are combination units. For special

combinations of features, special units, and detailed instructions regarding their

use, consult the factory.

10. Single Set-Point Photohelic

®

: The single set-point Capsu-Photohelic

®

is furnished with the right set-point only. Terminals in Section A and B (Figure 6)

are connected to this relay. Circuit Style SRH is wired for automatic reset as in

paragraph 5 above. Manual reset is accomplished by adding a normally closed

reset switch or push button to the circuit as described in paragraph 6 above.

11. Single Set-Point Special: Manual reset after actuation on falling pressure can be

obtained by using Circuit Style SRL. Consult the factory for special units and

detailed instructions regarding their use.

12. Placing in Service: In normal operation each relay is de-energized when the

pressure applied to the instrument is below its set-point. Special low-latching units

will ordinarily have to be reset before placing on the line in normal operation.

13. Failure Mode: The Capsu-Photohelic

®

circuit design provides certain

protection in the event of a loss of pressure or electrical power. In either case,

both relays will de-energize, returning to their normal "zero pressure" state. The

exceptions to this are models with center zero ranges. Because the relays on all

standard models are always energized when the indicating (black) pointer is to

the right of their respective set-points, the relay action on loss of pressure will

depend on set-point position, since either of them could be located to the left of

zero. As an example; if the left pointer were set at -2 in. w.c. and negative pressure

was -3 in. w.c., a loss of that pressure would allow the black pointer to return to

the center and thus cause the low set-point relay to energize.

If the LED should fail, only the left-low relay will de-energize. The right-high relay

will react as if pressure were above its set-point and will remain energized even

though pressure might be below that setting. In this situation, only termination of

electrical power will allow the right-high relay to de-energize.

MAINTENANCE/REPAIR

Upon final installation of the Series 43000 Capsu-Photohelic

®

Switch/Gage, no routine

maintenance is required. The Series 43000 is not field serviceable and should be

returned if repair is needed (field repair should not be attempted and may void

warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website. Contact

customer service to receive a Return Goods Authorization number before shipping

the product back for repair. Be sure to include a brief description of the problem plus

any additional application notes.

RESET

RESET

NC

NC

NO

NO

Manual Reset with Circuit HH

Figure 8

Do not apply electrical current to terminals in Sections B and C.

CAUTION

RESET JUMPER

117 VOLT LINE

1/6 HP*

117 VOLT

LOAD

High-Low Limit Control

Figure 9

(Circuit HH)

*Note: For larger motors, use the Capsu-Photohelic

®

in a maintained contact, 117

Volt Control or Push Button Circuit of the motor starter.

B-34:E-56atex 2/22/11 9:15 AM Page 4