Dwyer 43000 User Manual

Page 2

INSTALLATION

1. Location: All parts of the Capsu-Photohelic

®

pressure switch/gage

are ruggedly constructed and will stand a moderate amount of vibration, physical

shock and handling. Normal care in handling and installation is all that is

required. In cases where instrument panel vibration is severe, the panel should

be mounted or the amplifier-relay unit mounted remotely on a more stable

surface.

Select a location where the ambient temperature will not exceed 120°F.

Pneumatic pressure sensing lines may be run any necessary distance. For

example, 250 foot sensing lines will not affect accuracy but will damp the reading

slightly. Do not restrict lines. If pulsating pressure or vibration causes excessive

pointer oscillation or relay chatter, consult factory for additional damping means.

See accessory Bulletin S-101 for fittings.

2. Position: The Capsu-Photohelic

®

may be mounted as an integral package

or the amplifier-load relay assembly and housing may be mounted remotely from

the indicating gage-phototransistor unit. Extension cords with 7 pin plugs and

receptacles are available from Dwyer for interconnection of the two units.

All standard units are calibrated for use with the diaphragm and scale in a

vertical position. Special factory calibration is available for applications requiring

inclined or horizontal positions. The exceptions are ranges under 5 in w.c. which

are only available for vertical installation.

3. Mounting: The Capsu-Photohelic

®

is normally mounted before making

electrical connections, as the electrical enclosure is independent of the mounting

means and may be removed at any time.

A. Panel Mounting: Normal mounting is flush or through panel as shown in

Figure 2. Be sure to allow 4-3/8˝ extra space behind the unit for electrical

enclosure removal. Make a single 4-13/16˝* diameter hole in the panel.

Insert the entire Capsu-Photohelic

®

unit from the front, then slip on

the mounting ring and snap ring from the rear. Seat the snap ring in its

groove, back up the mounting ring against snap ring and tighten the four

(4) 1-1/4˝ No. 6-32 clamp screws provided. If behind panel space is critical,

the amplifier-relay unit can be mounted remotely. See the Remote-Relay

Mounting Instructions for details.

B. Gage Mounting with Relay Package Remote: Where it is preferred to

install the amplifier-relay unit separate from the gage, (usually due to

space limitations) the gage may either be panel mounted as shown in

Figure 2 or surface mounted as in Figure 3A. For surface mounting, use

the hole layout in Figure 3B.

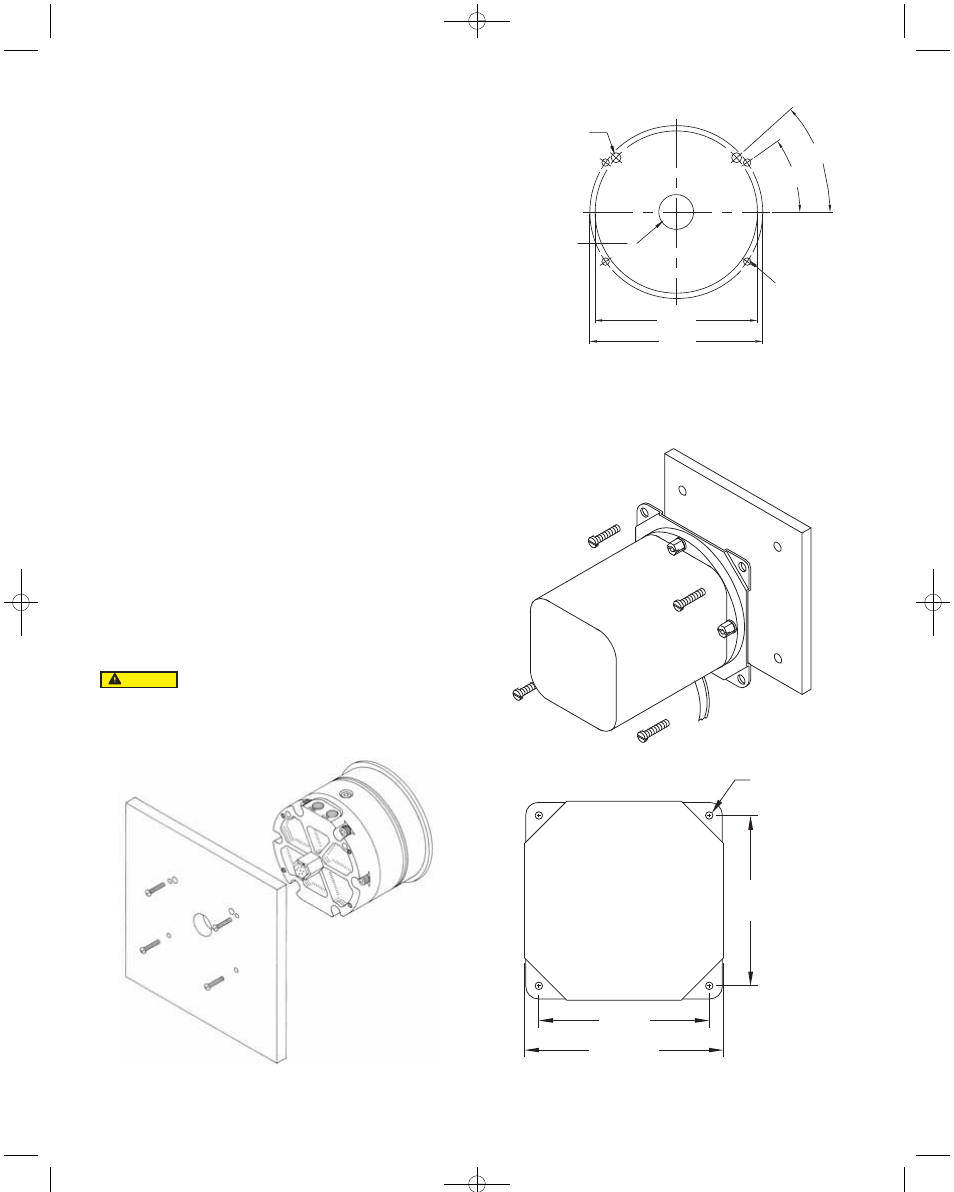

C. Remote Relays Mounting: The amplifier – relay unit may be mounted remotely

as shown in Figure 4A. Use the hole layout as shown in Figure 4B for this option.

Additional mounting information for special requirements is available from the

factory.

When the gage is surface mounted, two 1/4˝ diameter holes

must be located as shown for blow-out protection. This assures

that if the gage is overpressured, thus causing a failure, pressure will be safely

vented out the back. Failure to keep these holes clear could result in personal injury

and/or property damage since the excessive pressure could be forced into the front

cover which would then blow off.

CAUTION

A: Surface Mounting

ш4-1/8

[103.58]

Ш4-3/8

[110.33]

7/8˝ DIA. HOLE

(2) 1/4 DIA. HOLES FOR

BLOWOUT PASSAGE

42° TYP.

(2) HOLES

35° TYP.

(4) HOLES

(4) 3/16 DIA. HOLES

B: Hole Layout (Front)

Figure 3

A: Remote Amplifier-Relay Unit

4-9/32

[108.74]

5

[127.00] SQ

4-9/32

[108.74]

ø3/16

TYP 4 PLACES

B: Hole Layout

Figure 4

B-34:E-56atex 2/22/11 9:15 AM Page 2