Grounding, Protective grounding ring, Any position) straight pipe run – Badger Meter 7500 Series Mag Meter User Manual

Page 3

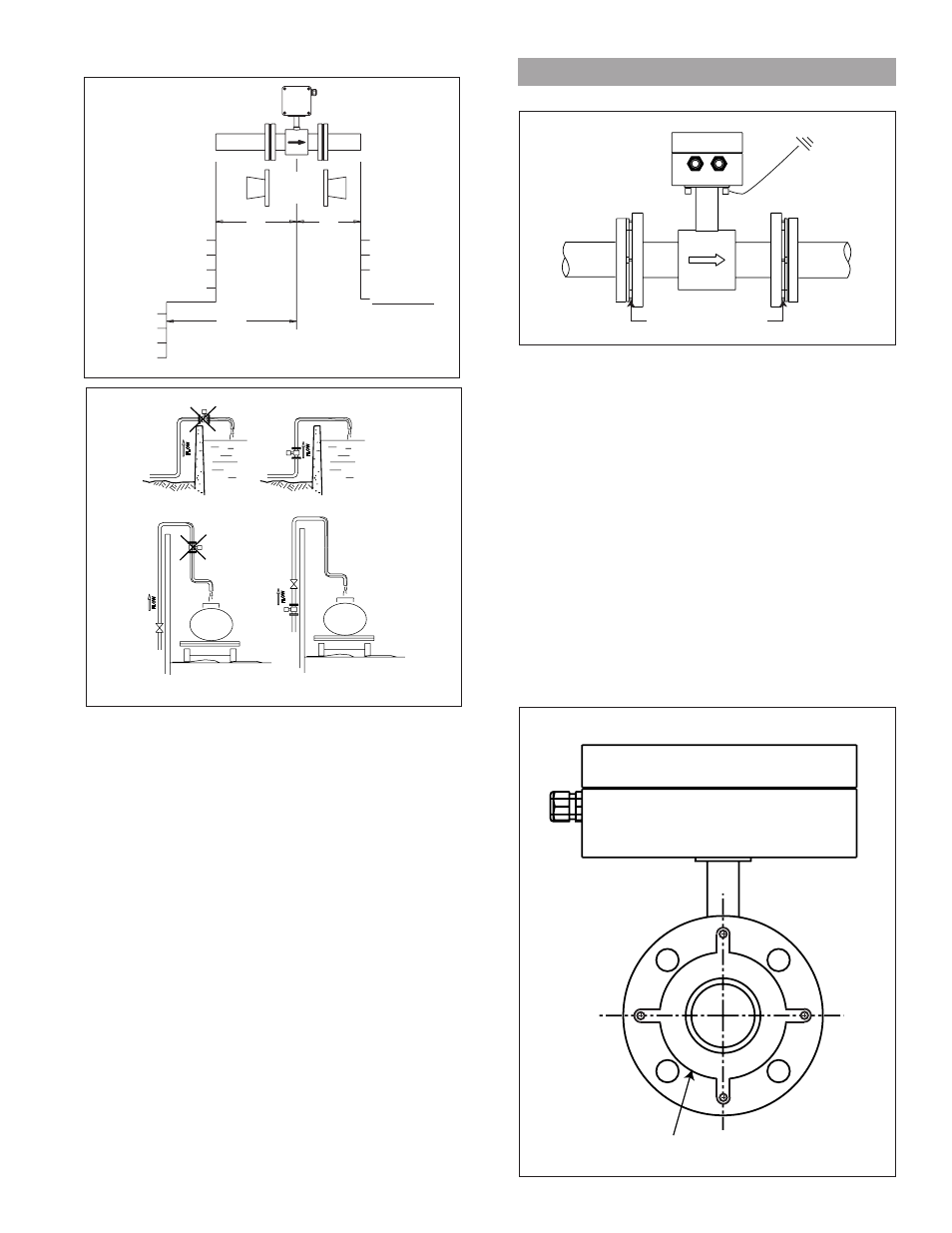

PIPING CONFIGURATION

PARTIALLY FULL PIPE SITUATIONS

Magnetoflow

®

meters are designed to operate in closed, full

pipes.

It is relatively common to encounter situations where the pro-

cess pipe will remain momentarily partially filled due to certain

hydraulic conditions. Examples of this include discharge to the

atmosphere (lack of back pressure), insufficient line pressure,

gravity flow applications, etc. (see figure above)

To eliminate the negative effect of these situations on the per-

formance of Magnetoflow® meters, a few guidelines should

be observed:

· Avoid installing the detector in the highest point of

the pipe line.

· Do not install the detector in vertical, downward flow

sections of the pipe.

· On-Off valves should ALWAYS be located on the

downstream side of the detector.

· Select the recommended vertical orientation when

ever possible.

· Make sure the selected detector size complies with

the application flow rate. Do not oversize pipe line

and detector size.

GROUNDING

Proper grounding is vital to ensure a good mag meter opera-

tion.

To ensure proper grounding, the 7500P mag meter is provided

with a set of protective grounding rings. The rings also serve

as protection for the liner.

The main purpose of the ground connection is to provide

electrical continuity between the liquid media, the amplifier’s

input ground or zero voltage reference, and a good, solid earth

ground.

Connect a grounding strap to a solid, local earth ground (tower

structure or pipe support) (see illustration). It is recommended

to use copper wire, at least gauge AWG 12.

When installing meter, also use standard gaskets to avoid

leaks.

3

WRONG

RIGHT

FL

O

W

FL

O

W

FL

O

W

WRONG

FL

O

W

RIGHT

Protective Grounding Rings

Good Local

Earth Ground

Protective Grounding Ring

(ANY POSITION)

STRAIGHT PIPE RUN

PUMP

CHECK VALVE

NEEDLE VALVE

GLOBE VALVE

(FULLY OPENED)

GATE VALVE

BALL VALVE

TEE

ELBOW

NO PUMPS

ANY VALVE

TEE

NO REQUIREMENT

PIPE REDUCERS

5-7 D

2 D

3 D

ELBOW

UPSTREAM

DOWN STREAM