Badger Meter 7500 Series Mag Meter User Manual

Page 2

2

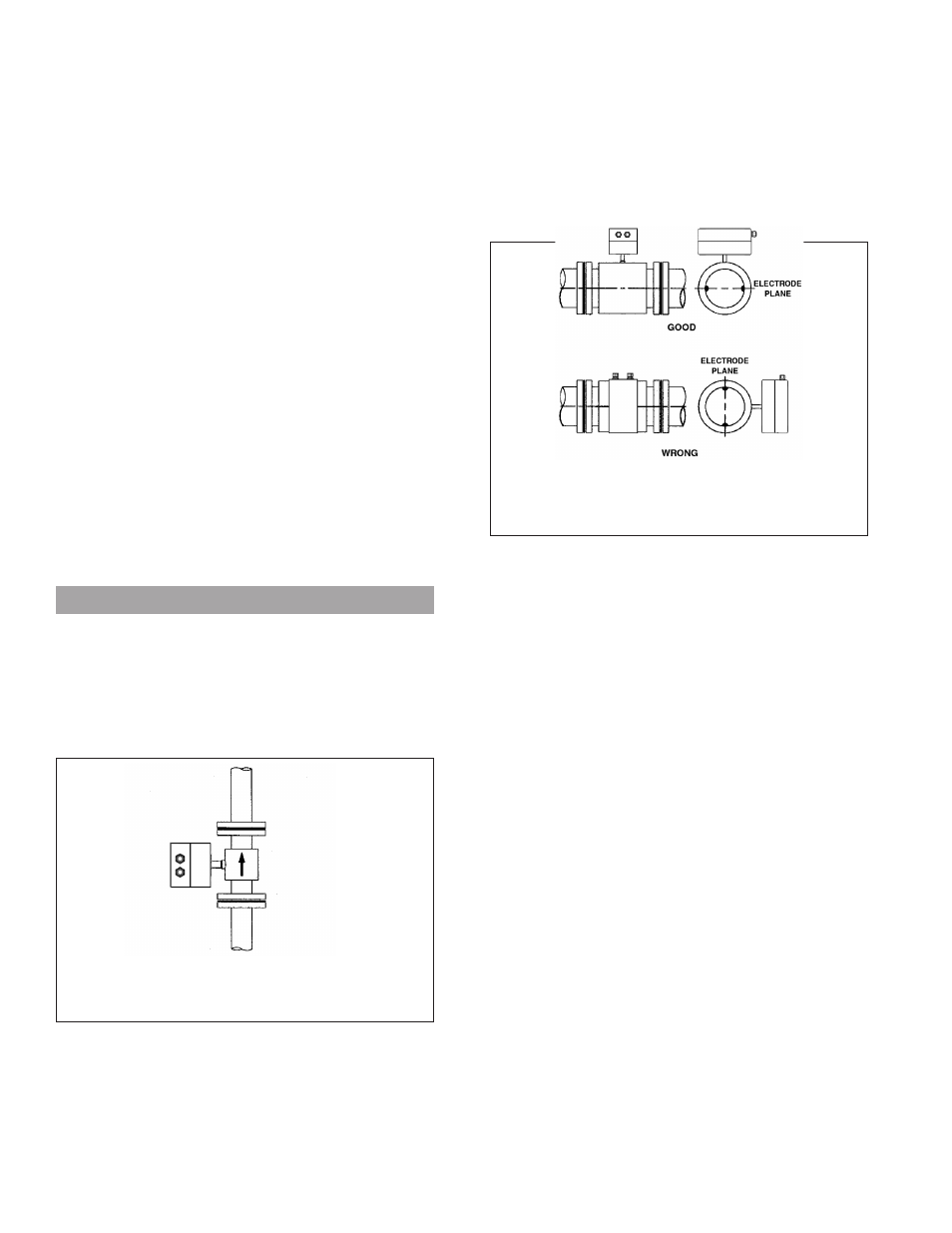

METER ORIENTATION

Magnetoflow Mag Meters can operate accurately in any pipe

line orientation.

However, the most recommended installation position is vertical

piping, with the the liquid flowing upward.

This installation practice ensures two objectives:

· The pipe remains completely full of liquid, even at low flow, low

pressure applications with a discharge to the atmosphere.

· Solid build-ups or sediments that could be part of the pro-

cess fluid will not deposit or accumulate on the liner and/or

electrodes.

The model 7500P mag is designed to measure flow in one direc-

tion only.

Carefully observe the "forward flow" label attached

to the meter body and install the meter accordingly.

If horizontal piping orientation is required, the detector should

be mounted in a position at which the electrodes axis will

remain in an horizontal plane (3 and 9 o’clock position; see

figure below).

PIPING CONFIGURATION

Appropriate piping arrangements should be provided to ensure

the meter is not exposed to extreme pipe vibrations. The piping

arrangements should include appropriate pipe supports.

For optimum accuracy performance, it is required to provide

sufficient inlet and outlet straight pipe runs. An equivalent of

3 diameters of straight pipe is required on the inlet side of the

meter, and 2 diameters on the outlet side, measured from the

center of the meter body.

Avoid installing the detector close to flow disturbance generat-

ing valves and fittings.

Do not install the detector in the outlet side of Piston or Dia-

phragm type pumps. Avoid all pipe locations where the flow

is pulsating. Avoid installing the detector in the suction side

of any pumps; possible creation of vacuum can affect meter

performance or cause damage to the PTFE liner.

TEMPERATURE

Note: Environmental temperature of installation is not to exceed

maximum specification of 122°F (50°) for the meter.

METER INSTALLATION

FIG. 1

VERTICAL PIPE MOUNTING

HIGHLY RECOMMENDED

FIG. 2

HORIZONTAL INSTALLATION

ELECTRODES ORIENTATION

UNPACKING AND INSPECTION

To avoid damage in transit, Badger meters are shipped to

the customer in a special shipping container. Upon receipt

of the meter, perform the following unpacking and inspection

procedures. If damage to the shipping container is evident, be

present when the meter is unpacked.

A. Carefully open the shipping container following any instruc-

tions that may be marked on the container. Remove all cush-

ioning material surrounding the meter and carefully lift meter

from container. Retain the container and all packing material

for possible use in reshipment or storage.

B. Visually inspect the meter for any physical damage such as

scratches, loose or broken parts, or any other sign of damage

that may have occurred during shipment.

NOTE: If damage is found, request an inspection by the car-

rier's agent within 48 hours of delivery. Then file a claim with

the carrier. A claim for equipment damaged in transit is the

responsibility of the customer.

STORAGE

If the meter is not to be installed right away, store it in it's original

container in a dry, sheltered location. Storage temperature: -4

to 158°F (-20 to +70°C)