Operating principle, Specifications – Badger Meter High Temperature Fluid Meter User Manual

Page 6

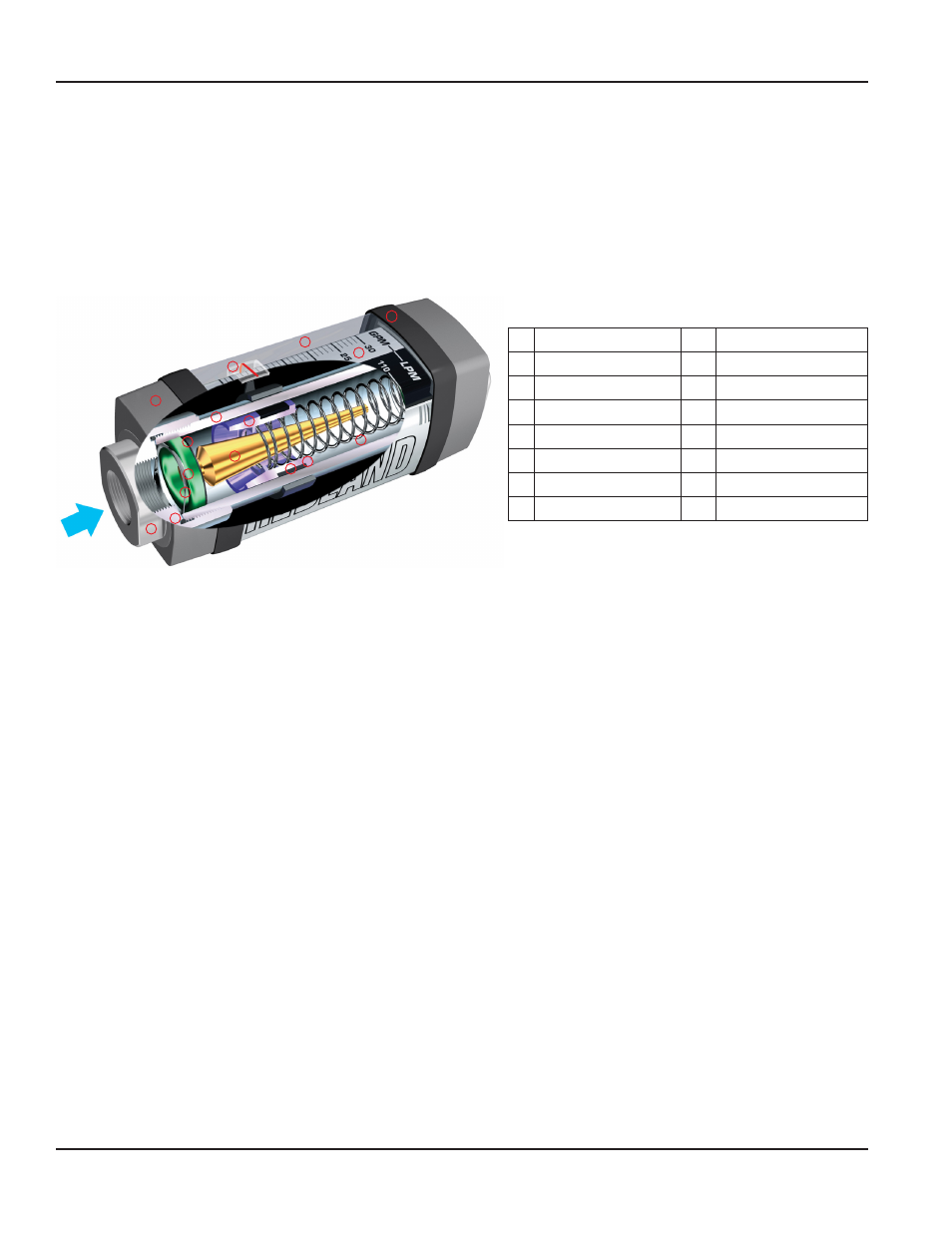

OPERATING PRINCIPLE

The Flow Meter is a variable area instrument . A sharp-edged Orifice, located within the Piston Assembly, forms an

annular opening with the contoured Metering Cone . The piston assembly carries a cylindrical PPS/Ceramic Magnet that

is magnetically coupled to an external Indicating Magnet which moves precisely in direct response to movement of the

piston . A calibrated Spring opposes flow in the forward direction .

The Hedland variable area flow meters are the most readable products in their class . Brightly colored indicators move over the

graduated, linear Flow Scale which contains bold, easy to read numeral and gauge marks . The enhanced resolution virtually

eliminates parallax problems associated with competitive, direct reading flow meters .

16

1

2

3

11

4

5

6

7

8

9

10

12

13

14

15

FLO

W

1 Orifice

9

Spider Plate

2 Piston Assembly

10 Retaining Spring

3 Metering Cone

11 Pressure Seal

4 Internal Magnet

12 End Fitting

5 Flow Indicator

13 End Cap

6 Spring

14 Body

7 Flow Scale

15 Guard

8 Retaining Ring

16 Guard Seal/Bumper

Table 1: Meter components

SPECIFICATIONS

Temperature Range

• Standard: –20…240° F (–29…116° C)

• High temperature and hostile environment

◊ –20…400° F (–29…205° C) continuous

◊ 400…500° F (205…260° C) intermittent

• See

"Flow vs Pressure Drop*" on page 18

Pressure Rating (3:1 safety factor)

• Aluminum/brass models: 3500 psi (241 bar) maximum

• Stainless steel models:

◊ 1/4" & 1/2" sizes: 6000 psi (414 bar) maximum

◊ 3/4" thru 1-1/2" sizes: 5000 psi (345 bar) maximum

Pressure Drop

• See

"Application Information" on page 16

for specific

meter information

Accuracy

• ±2% of full scale

Repeatability

• ±1%

Threads

• SAE J1926/1, NPTF ANSI B2 .2, BSPP ISO1179, Code 61

and Code 62: SAEJ518

Test Kit Pressure Gauge, Glycerin Dampened

• Aluminum/brass models: 0…3500 psi (0…240 bar)

• Stainless steel models: 0…6000 psi (0…400 bar)

Test Kit Load Valve

• 1/2", 3/4" and 1" sizes: needle valve

• 1-1/4" and 1-1/2" sizes: ball valve

• Produce ΔP up to 3500 psi (241 bar) PSID and 6000 psi

(414 bar) PSID

Dimensions

• See

Inline Liquid Flow Meter

Page 6

November 2013