Badger Meter Hydrometer User Manual

Page 10

Section I

Paragraphs 1-49 to 1-54

1-49. REPAIR OF VALVES. If the valve becomes worn or

defective, replacement parts may be purchased from the

manufacturer. See Section II for detailed parts lists.

1-50. SHIPMENT.

1-51. The flowmeter should never be shipped unless carefully

boxed and fully protected. Floats, 3/8 inch and larger, must be

removed from tubes and wrapped separately to prevent

damage.

1-52. STORAGE.

1-53. If flowmeter is to be placed in storage, fill tube with oil

SAE-10 and open all valves.

CAUTION

For oxygen service flowmeters, clean with

Freon after storage.

1-54. TROUBLESHOOTING.

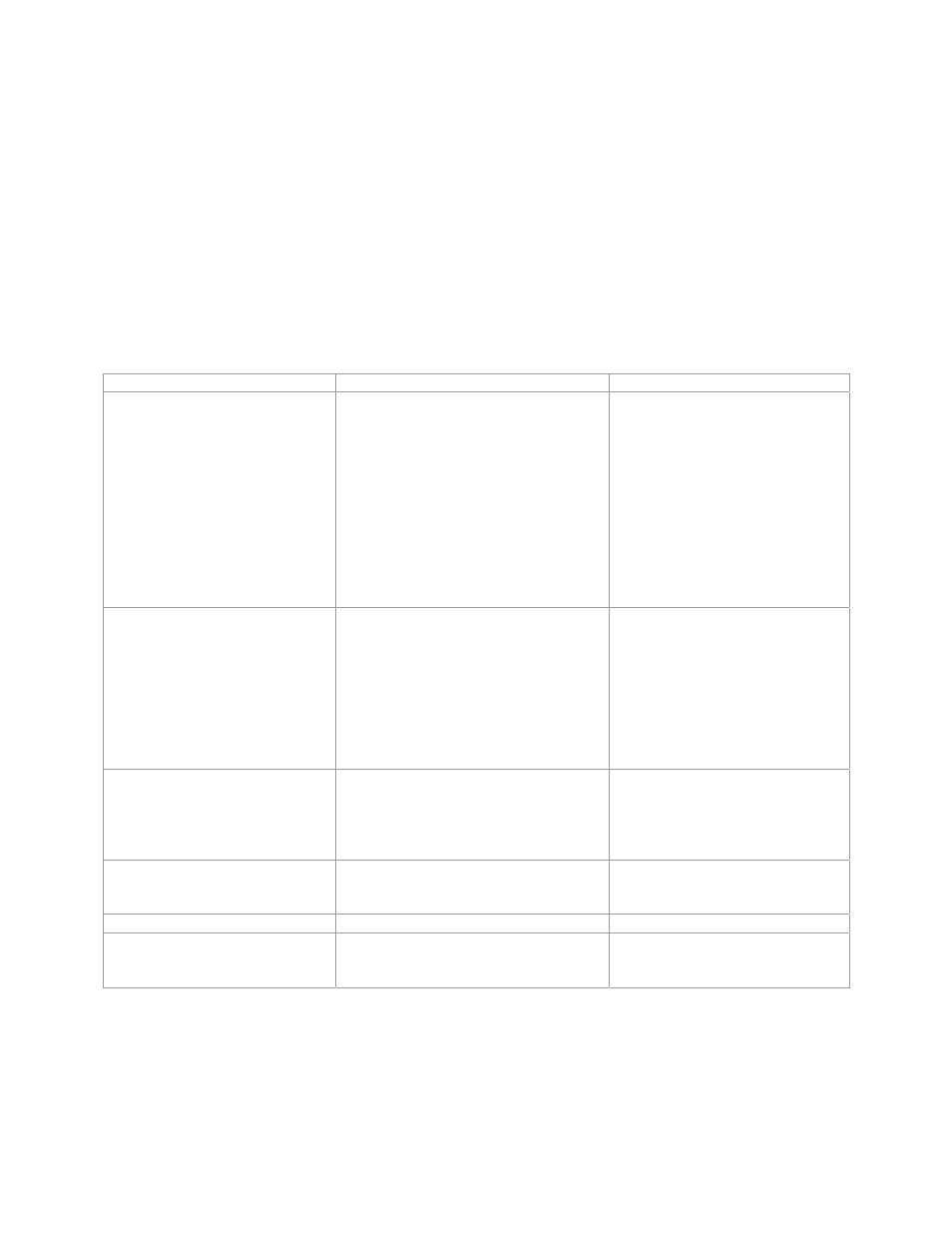

TROUBLE

POSSIBLE CAUSE

REMEDY

READINGS TOO HIGH

Temperature of fuel below

specifications.

Viscosity of fuel higher than specified.

Dirty floats or metering tubes.

Leaks in gaskets in tubes of higher

capacity than tube being read.

Leak between instrument and test unit (if

on outlet side).

Correct temperature.

Use specified fuel if possible.

Clean (par. 1-40).

Replace gaskets (par. 1-44).

Check for and repair leakage.

READINGS TOO LOW

Temperature of fuel above

specifications.

Viscosity of fuel lower than specified.

Leaks through bypass valves.

Leak between instrument and test unit (if

on inlet side).

Correct temperature.

Use specified fuel if possible.

Check valves are correct.

Check for and repair leakage.

READING INACCURATE

(EITHER HIGH OR LOW)

Reading taken improperly.

Scales improperly set.

Eye must be on level with float top

(par. 1-35).

Align scale and tube red index lines

(par. 1-41).

FLOATS FLUCTUATE

Pump surge reaches instrument.

Air in system.

Install surge trap or change pump.

Bleed air (par. 1-33).

FLOAT STICKS IN TUBE

Tube or float dirty.

Clean (par. 1-40).

EXCESSIVE PRESSURE DROP

THROUGH INSTRUMENT

Closed bypass valves.

Float sticks.

Check and correct valves.

Clean float (par. 1-40).

8