Specifications, Materials of construction, Operating parameters – Badger Meter 1100 User Manual

Page 4: Installation, Materials of construction operating parameters, Avertissement

Turbine Flow Meter, 1100 Series

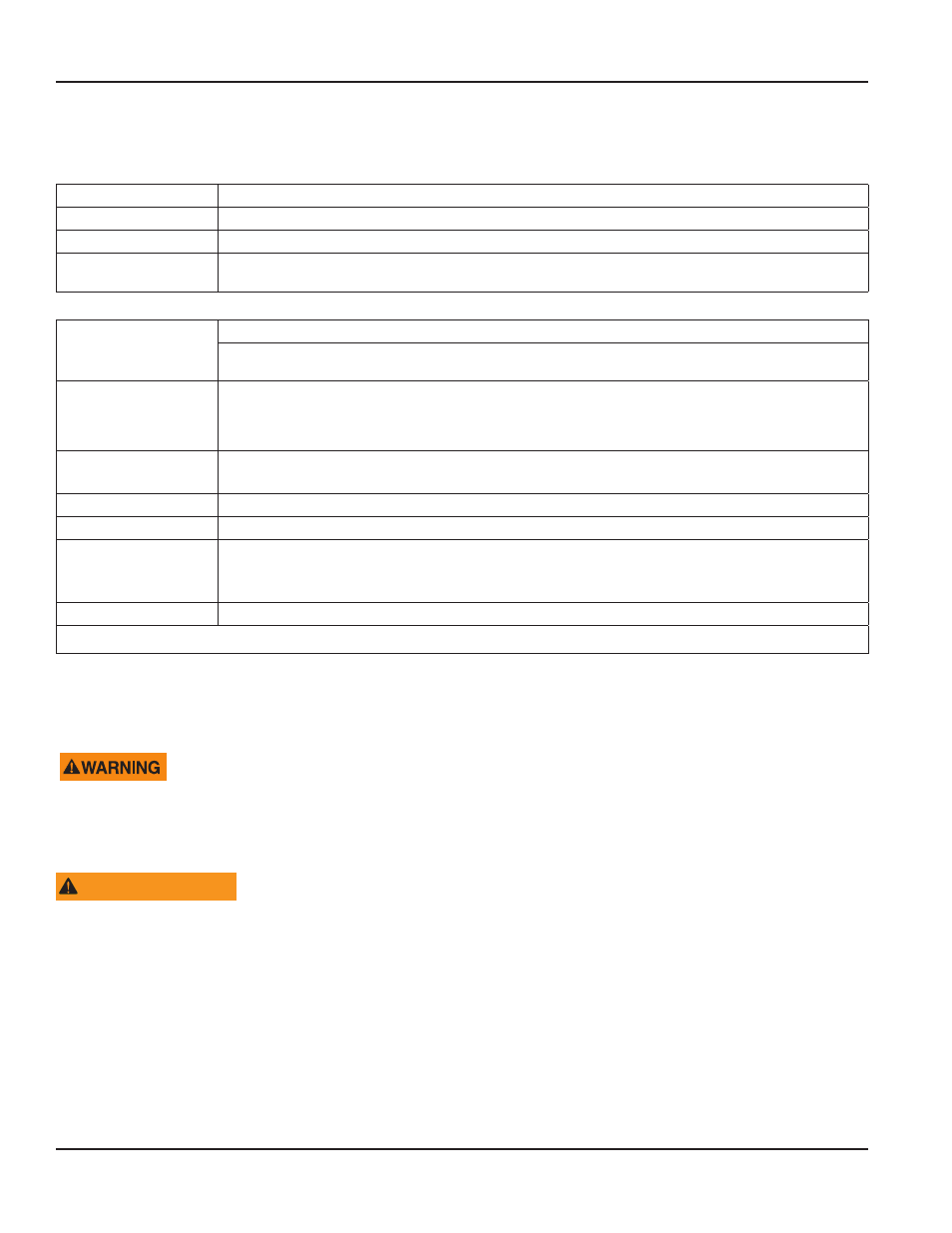

SPECIFICATIONS

Materials of Construction

Body

316 Stainless Steel

Rotor

CD4MCU Stainless Steel

Rotor Support

316 Stainless Steel

Rotor Shaft and

Bearing

Tungsten Carbide

Operating Parameters

Temperature

–150…350° F (–101…177° C) .

The meter should not be subjected to temperatures above 350° F (177° C), or below –150° F (–101° C) or the

freezing point of the metered liquid .

Pressure

Maximum pressure ratings as follows:

5000 psi for all NPT meters up to 2 in .

3000 psi for 3 in . and 4 in . Grayloc meters .

800 psi for 3…10 in . grooved end meters .

Accuracy

±1% of reading for 7/8 in . and larger meters .

±1% of reading over the upper 70% of the measuring range for 3/8 in ., 1/2 in ., and 3/4 in . meters .

Repeatability

±0 .1% .

Calibration

Water (NIST traceable calibration) .

Approvals

“Single Seal”: ANSI/ISA 12 .27 .01-2003; MWP 5,000 PSI (34 .5 MPa), 350° F .

I .S . Entity Parameters with Badger Meter B111109 standard magnetic pickup installed:

Vmax = 10V, Imax = 7mA, Ci = 0µF, Li = 0 .9H

End Connections

NPT, BSP, Victaulic, Flange, and Hose Barbed .

*Contact the factory for ordering options .

OTEE:

N

Consult factory for pressure ratings for flanged meters .

INSTALLATION

PRESSURE IN EXCESS OF ALLOWABLE RATING MAY CAUSE THE HOUSING TO BURST AND CAUSE SERIOUS

PERSONAL INJURY.

AVERTISSEMENT

LA PRESSION AU-DESSUS DE L’ESTIMATION PERMISE PEUT FAIRE ÉCLATER ET CAUSER LE LOGEMENT LE DOMMAGE

CORPOREL SÉRIEUX.

1 . Check the internals of the flow meter for any foreign material . Make sure the turbine rotor spins freely prior to installation .

Also, check fluid lines and remove any debris found .

2 . Install the flow meter with the flow arrow, etched on the exterior of the meter body, pointing in the direction of fluid flow .

Though the meter is designed to function in any position, where possible, install it horizontally with the conduit adapter

facing upward .

3 . Thread a magnetic pickup (Badger Meter model B111109 or equivalent) into the conduit adapter completely finger tight

without forcing . Secure with a lock nut if supplied .

4 . Install conduit or other fittings suitable for the installation area onto the conduit adapter hub on the flow meter .

Page 4

July 2014