Troubleshooting guide – Badger Meter 1100 User Manual

Page 11

Part number information

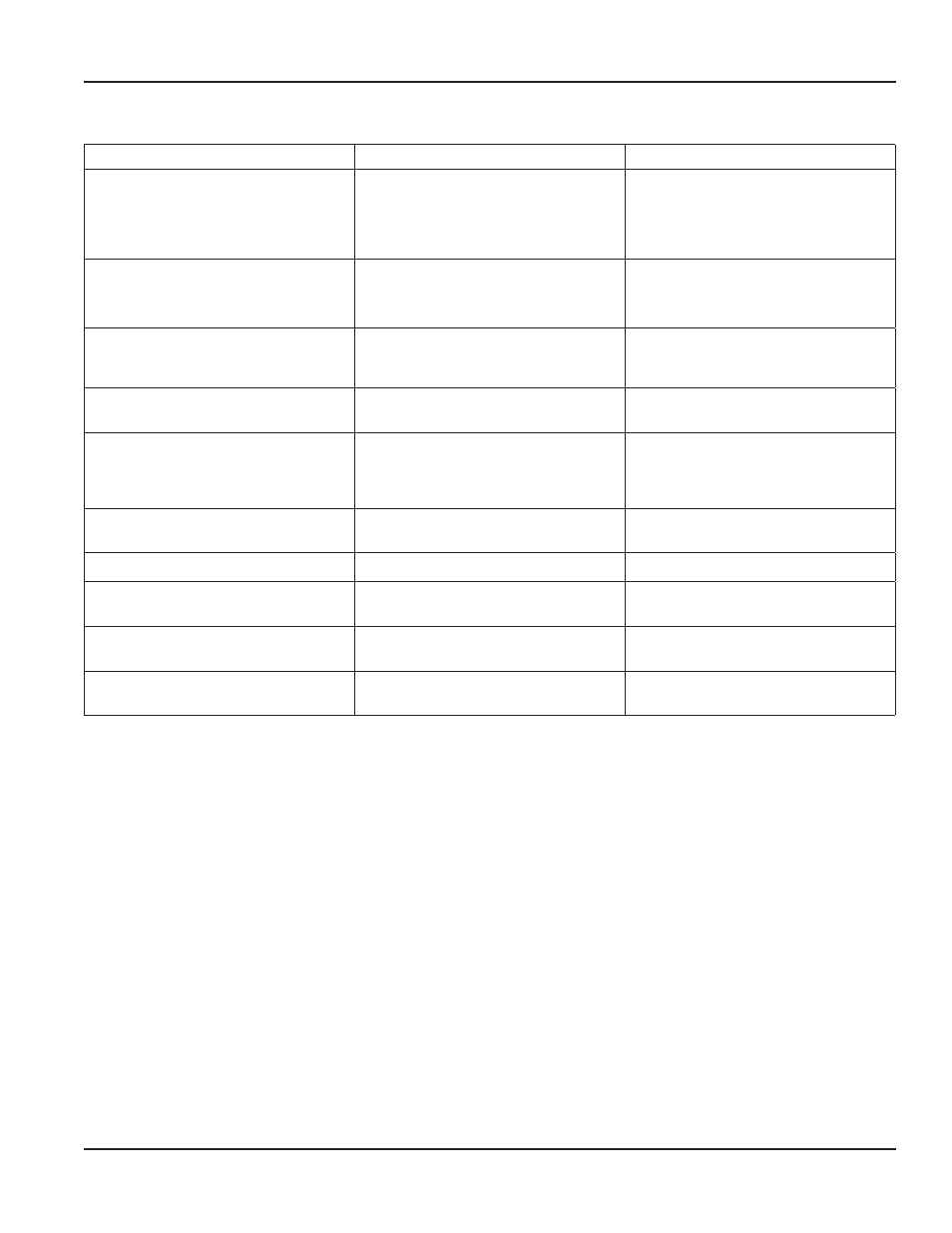

TROUBLESHOOTING GUIDE

Trouble

Possible Cause

Remedy

Meter indicates higher than actual flow rate

Cavitation .

Debris on rotor support .

Build up of foreign material on meter bore .

Gas in liquid .

Increase back pressure .

Clean meter .

Clean meter .

Install gas eliminator ahead of meter .

Meter indicates lower than actual flow rate .

Debris on rotor .

Worn bearing .

Viscosity higher than calibrated .

Clean meter and add filter .

Clean meter and add filter .

Recalibrate monitor .

Erratic system indication, meter alone works

well (remote monitor application only) .

Ground loop in shielding .

Ground shield one place only . Look for

internal electronic instrument ground .

Reroute cables away from electrical noise .

Indicator shows flow when shut off .

Mechanical vibration causes rotor to

oscillate without turning .

Isolate meter .

No flow indication .

Full or partial open position .

Fluid shock, full flow into dry meter or

impact caused bearing separation or

broken rotor shaft .

Rebuild meter with repair kit and recalibrate

monitor . Move to location where meter

is full on startup or add downstream flow

control valve .

Erratic indication at low flow, good

indication at high flow .

Rotor has foreign material wrapped around

it .

Clean meter and add filter .

No flow indication .

Faulty pickup .

Replace pickup .

System works perfect, except indicates

lower flow over entire range .

By-pass flow, leak .

Repair or replace bypass valves, or faulty

solenoid valves .

Meter indicating high flow, upstream piping

at meter smaller than meter bore .

Fluid jet impingement on rotor .

Change piping .

Meter indicating low flow, upstream piping

at meter smaller than meter bore .

Viscosity lower than calibrated .

Change temperature, change fluid or

recalibrate meter .

Page 11

July 2014

TUR-UM-00014-EN-03