Part number information, Attention, New turbine kit installation mportant i – Badger Meter 1100 User Manual

Page 10

Turbine Flow Meter, 1100 Series

New Turbine Kit Installation

MPORTANT

I

Before reassembly, note that an arrow is cast or engraved on each component. The arrow indicates the primary flow direction. When

reassembled, the arrowheads must point in the direction of the fluid flow. The arrows must also be oriented in the up position on

both rotor supports. The magnetic pickup side of the body signifies the up position. Performance of repair kit calibration is in the up

position. Reinstallation of the repair kit in the up position ensures continuation of accurate measurements.

, and

show the proper alignment and orientation of the repair kits.

OTEE:

N

Fractional size (3/8 in ., 1/2 in . and 3/4 in .) rotors do not contain a cast or engraved arrow . However, a colored cap

on the downstream side of the rotor shaft indicates flow direction . Remove this cap before assembly, noting

flow direction .

1 . Install one of the rotor supports into the body bore, noting the orientation of the arrow .

2 . Secure a retaining ring in the groove provided . Check for complete installation of retaining rings in each groove .

OTEE:

N

4 in . and larger meters have a retaining ring at both ends of the rotor (see

) .

3 . Insert the rotor and second rotor support in the opposite side of the body, noting the orientation of the arrow .

4 . Secure the second retaining ring in the opposite groove, using the same procedure as in step 2 above .

EXCESS AIR PRESSURE MAY DAMAGE THE ROTOR AND BEARINGS BY OVER SPINNING.

ATTENTION

LA PRESSION ATMOSPHÉRIQUE EXCESSIVE PEUT ENDOMMAGER LE ROTOR ET LES ROULEMENTS PRÈS AU-DESSUS DE

LA ROTATION.

5 . Check the meter by lightly puffing air through the assembly . If the rotor does not turn freely, disassemble the meter and

remove anything that might obstruct movement of the rotor .

OTEE:

N

At this time, electronics require recalibration . Refer to the display's user manual . If there are any questions on

recalibration, contact Badger Meter, Inc . or the manufacturer of the associated electronics .

6 . Install the magnetic pickup .

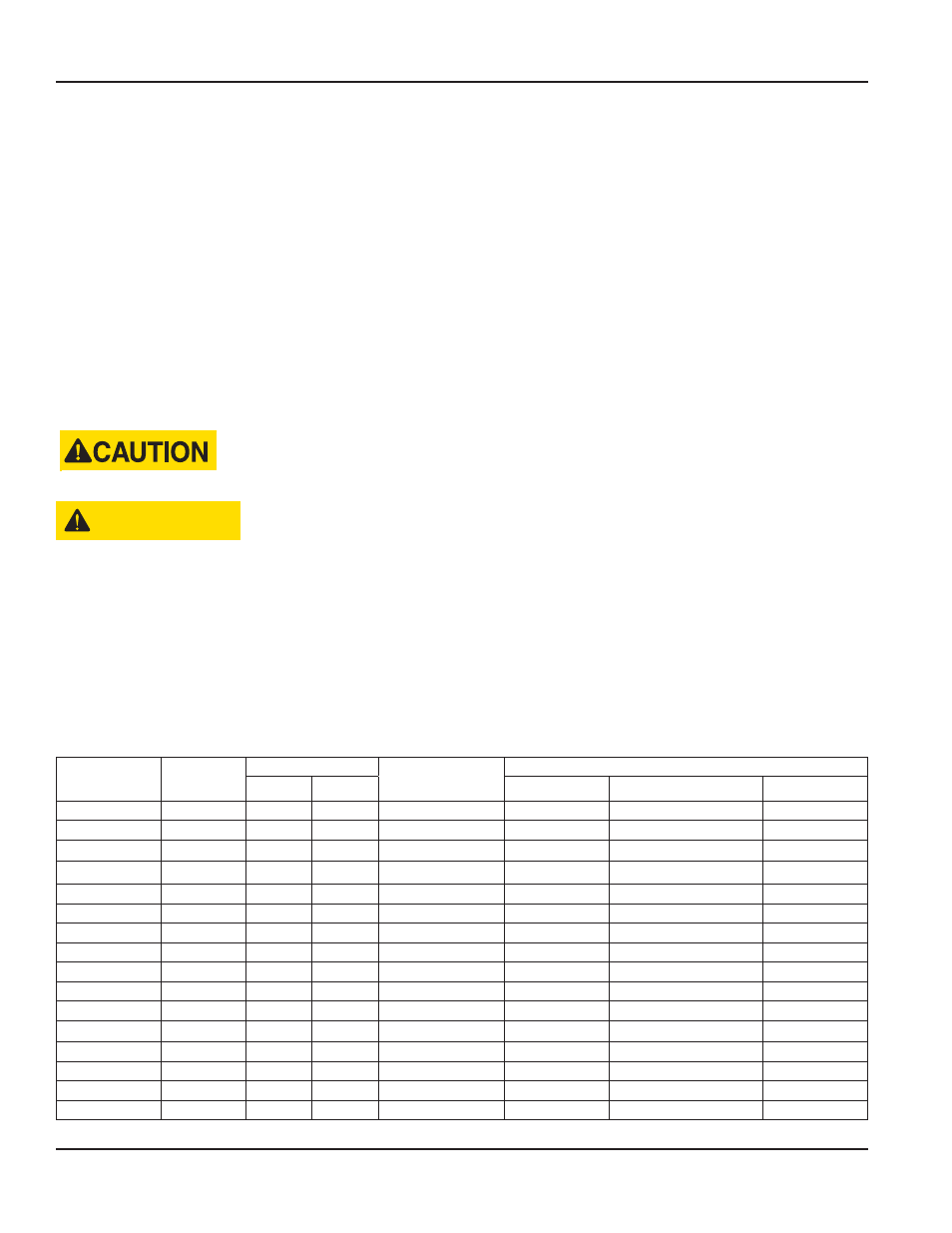

PART NUMBER INFORMATION

Part Number

Meter Size

End to End Length

End Connection

Flow Ranges

inches

mm

gpm

bpd

m³/d

B110-375-1/2

3/8 in .

3

76 .2

1/2 in . Male NPT

0 .6…3 .0

20…100

3 .3…16

B110-500-1/2

1/2 in .

3

76 .2

1/2 in . Male NPT

0 .75…7 .5

25…250

4 .1…41

B110-750-1/2

3/4 in .

3

76 .2

1/2 in . Male NPT

2…15

68…515

10 .9…81 .75

B110-375

3/8 in .

4

101 .6

1 in . Male NPT

0 .6…3 .0

20…100

3 .3…16

B110-500

1/2 in .

4

101 .6

1 in . Male NPT

0 .75…7 .5

25…250

4 .1…41

B110-750

3/4 in .

4

101 .6

1 in . Male NPT

2…15

68…515

10 .9…81 .75

B110-875

7/8 in .

4

101 .6

1 in . Male NPT

3…30

100…1000

16…160

B111-110

1 in .

4

101 .6

1 in . Male NPT

5…50

170…1700

27 .25…272 .5

B111-115

1-1/2 in .

6

152 .4

1-1/2 in . Male NPT

15…180

515…6000

82…981

B111-121

2 in . Low

6

152 .4

2 in . Male NPT

15…180

515…6000

82…981

B111-120

2 in .

10

254

2 in . Female NPT

40…400

1300…13,000

218…2180

B111-130

3 in .

12-1/2

317 .5

3 in . Grooved End

60…600

2100…21,000

327…3270

B111-140

4 in .

12

304 .8

4 in . Grooved End

100…1200

3400…41,000

545…6540

B111-160

6 in .

12

304 .8

6 in . Grooved End

200…2500

6800…86,000

1090…13,626

B111-180

8 in .

12

304 .8

8 in . Grooved End

350…3500

12,000…120,000

1363…19,076

B111-200

10 in .

12

304 .8

10 in . Grooved End

500…5000

17,000…171,000

2725…27,252

Page 10

July 2014