Glycol data, Optichill ™ chillers, Performance data – Airedale OptiChill FreeCool 500kW - 1365kW User Manual

Page 32

OPTICHILL

™

Chillers

32

Chillers

Technical Manual : 6530166 V1.6.0 02_2013

Performance Data

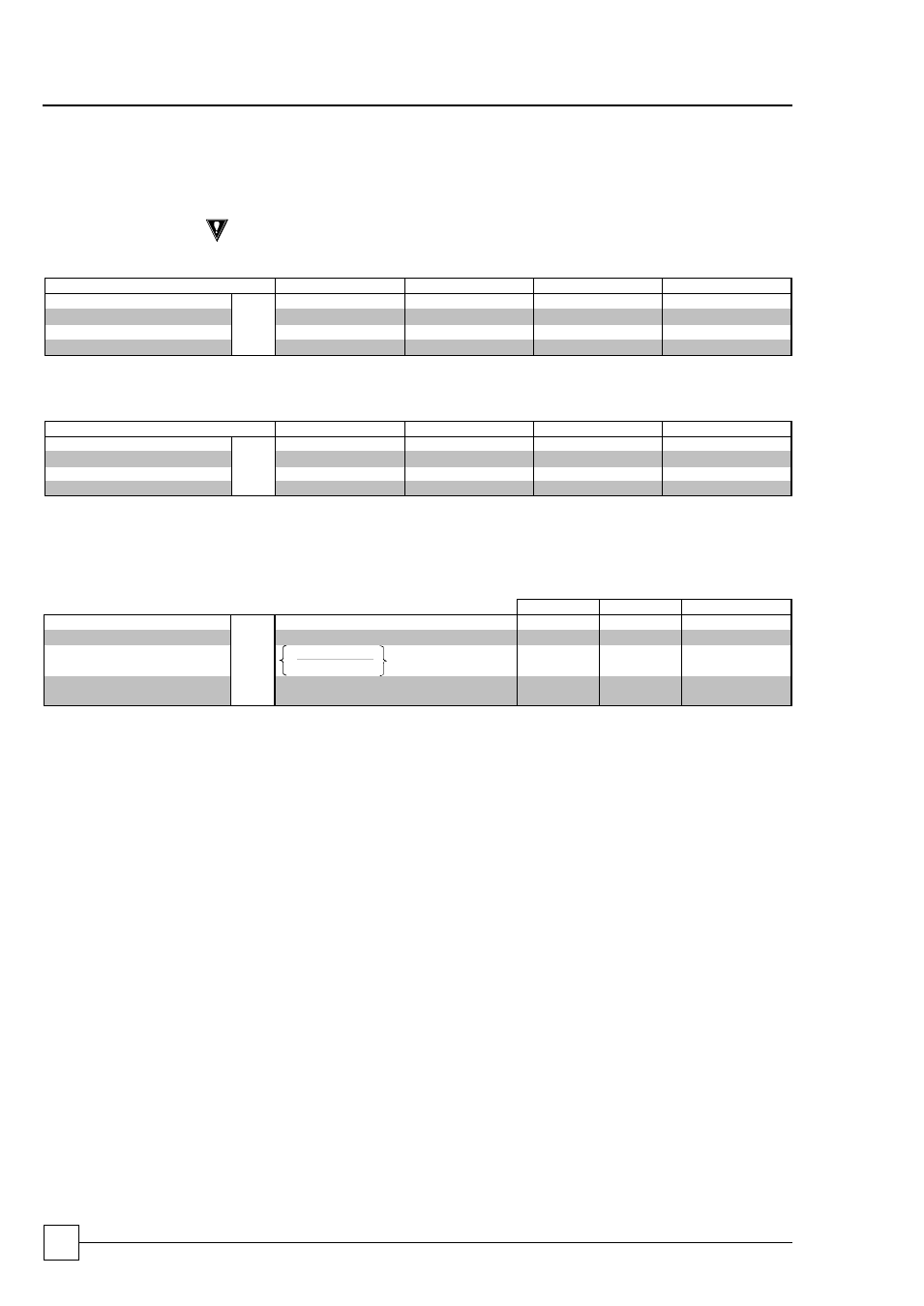

GLYCOL DATA

For a given percentage of glycol in the system there are correction factors that need to

be applied, the following tables can be used as a guide.

CAUTION

The source data must be at 100% Water for the correction factors to be valid.

Ethylene Glycol Nominal Correction Factors

Glycol in System / Freezing Point ºC

10% / -4°C

20% / -9°C

30% / -15°C

40% / -23°C

Output (kW)

x

0.98

0.97

0.95

0.93

Compressor Input (kW)

0.99

0.98

0.96

0.95

Water Flow (l/s)

0.99

1.02

1.04

1.07

Pressure Drop (kPa)

1.05

1.20

1.38

1.57

Propylene Glycol Nominal Correction Factors

Glycol in System / Freezing Point ºC

10% / -2°C

20% / -6°C

30% / -12°C

40% / -20°C

Output (kW)

x

0.97

0.95

0.91

0.88

Compressor Input (kW)

0.99

0.98

0.96

0.95

Water Flow (l/s)

0.98

0.97

0.95

0.95

Pressure Drop (kPa)

1.08

1.17

1.31

1.45

Example

Model Ref.

= OPC800HE+D14

Ambient:

= 35°C

Fluid

= 20% Ethylene Glycol

Inlet Fluid Temp.

= 7°C

Outlet Fluid Temp.

= 12°C (5°C

T)

100% Water

Multiplier Corrected Figure

Output (kW)

=

841.2

x 0.97

=

816.0 kW

Compressor Input (kW)

Input (kW) - TFP {283.1 - {14 x 1.7}} =

259.3

x 0.98

=

254.1 kW

Water Flow (l/s)

Output

40.2

x 1.02

=

40.8 l/s

4.19 x

ΔT

Pressure Drop (kPa)

Plot from curve (refer to

33.1

x 1.20

=

39.7 kPa

Where:

Output

= (kW) Output (kW), refer to

Compressor Input

= (kW) Input (kW) refer to

, on page 28, (-) Minus TFP

TFP

(Total Fan Power)

= (kW) Quantity of Fans to unit x Fan Motor Size, refer to

Water Flow

= (l/s) ALWAYS USE 100% water SHC of 4.19.

ΔT

= (°C) Difference of Entering Water and Leaving Water temperature