8 routine maintenance – Thermo Fisher Scientific CyberScan TB 1000 Turbidimeter User Manual

Page 11

CyberScan TB1000

8

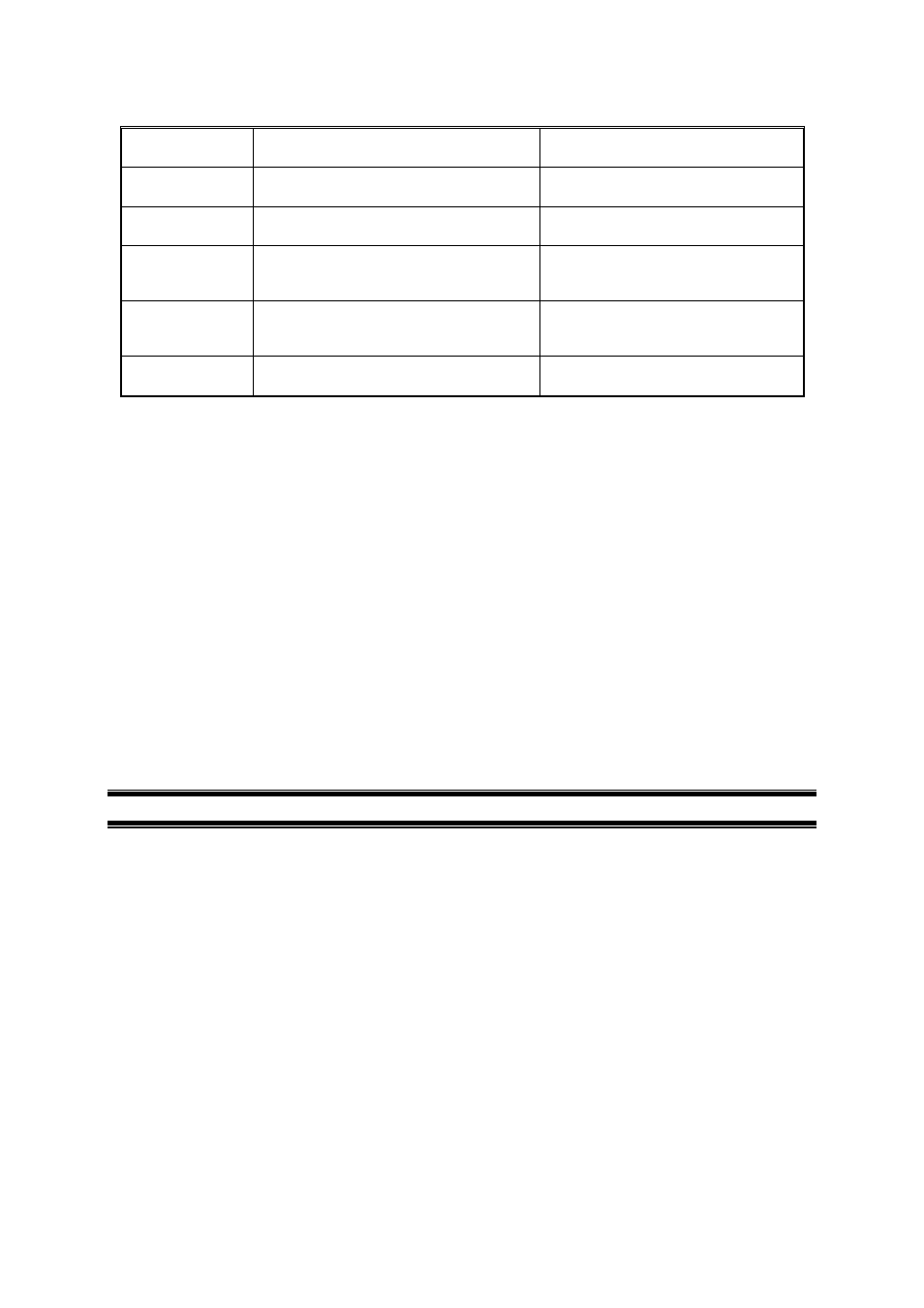

ERROR

MESSAGE

ASSOCIATED MEANING

TYPICAL CAUSE

E-01

Overall light level detected is too low during

calibration

Wrong standard is in the optical well or

lamp failure.

E-02

Overall light level detected is too high

during calibration

Wrong standard is in the optical well.

E-03

Amount of light detected between 0.02

NTU and 10.0 NTU is too small during

calibration

Wrong standard is in the optical well or

bad A/D circuitry.

E-04

Amount of light detected between10.0 NTU

and 1000 NTU is too small during

calibration

Wrong standard is in the optical well or

bad A/D circuitry.

E-05

Amount of light detected is too low during

normal mode

Lamp failure.

If errors 1-4 are noted, turn the instrument off and then back on. Once the instrument is back on, re-calibrate the

instrument. If the error persists, please contact the Eutech Instruments Customer Services Department to rectify

the error. (See Section 9.0)

If error 5 is noted, replace the lamp module with a spare lamp module. If you do not have a spare lamp module,

refer to Section 10.0 for ordering information.

7.3

Factory Default Parameters

The CyberScan TB1000 memory retains all original factory settings. At any time, you can force the instrument to

change back to these default settings. All calibration values and settable parameters (see section 5 & 6) will

change back to their original configurations. This is particularly useful if you feel that your calibration standards

may have been compromised. In this situation you may use the factory default parameters while waiting for new

standards to arrive from Eutech Instruments.

To invoke this option, first turn on the instrument. Next, press CAL key while holding down the ▲ key. The

instrument will continue operating in normal automatic mode with all adjustable parameters reset to factory default

conditions.

8 Routine

Maintenance

The CyberScan TB1000 has been designed for ease of use and simple operation. When not in use, ensure that

the instrument has been turned off and that a clean sample cuvette fitted with a black light shield cap has been

placed in the sample well. This will ensure that a minimal amount of dust and/or debris will be able to settle on

the optics of the instrument.

8.1

Cuvette Cleaning and Care

Proper measurement of the turbidity of a sample requires the use of a cuvette that is free of marks, smudges,

scratches and any bacterial growth. Cleaning the cuvette is accomplished by washing the interior and exterior of

the cuvette in a detergent solution. Once cleaned, the cuvette should be rinsed thoroughly 8 to 10 times with

clean distilled water to eliminate the possibility of detergent build-up and streaking. Cleaned and dried cuvettes

should be stored with the black light shield cap on the cuvette and can be stored in a cuvette rack (see

accessories and replacement parts list). During normal operation you may use any typical glass cleaner along

with a lint free cloth, or tissue, to clean the outside of the cuvettes.

8.2

Lamp Replacement

Periodically the lamp module will require replacement. Figure 1 illustrates the location of the lamp module. An

error message will be illuminated when it is time to replace the lamp (see section 7.2). It is recommended that

one spare lamp for each CyberScan TB1000 meter be kept on hand at all times to ensure continuous use of the

instrument.