SHIMPO TT-Series User Manual

Page 5

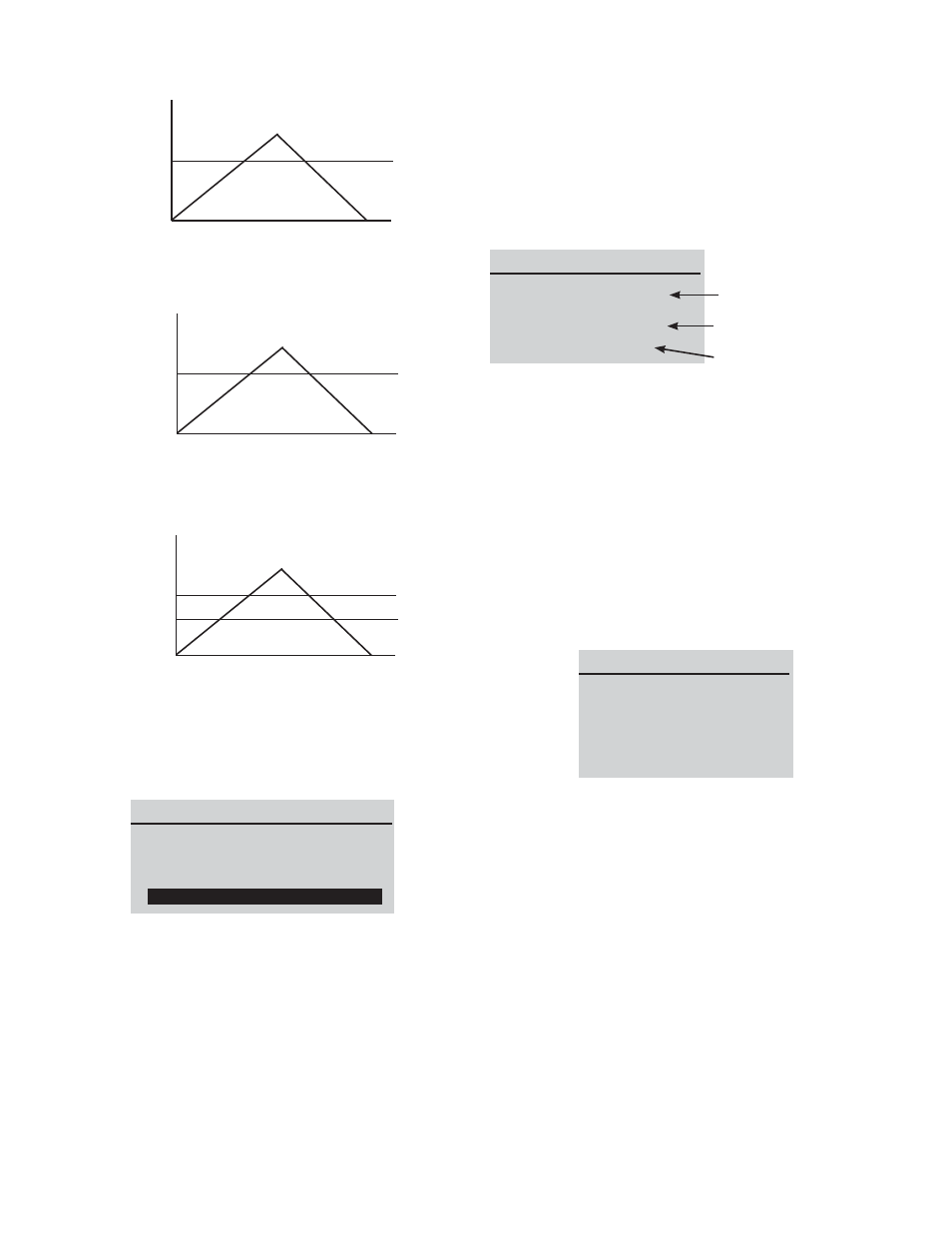

Example: LOWER LEVEL = 0 N.m, UPPER LEVEL = 20 N.m

Figure 6a

Example: LOWER LEVEL = 20 N.m, UPPER LEVEL = 0 N.m

Figure 6b

Example: LOWER LEVEL = 10 N.m, UPPER LEVEL = 20 N.m

Figure 6c

2) MEMORY: The TT offers the ability to view saved records, de-

lete last or delete all records. It can also upload the data if con-

nected to a PC. To access, in the menu list highlight Memory and

press ENTER.

Figure 7: Memory Menu

In the VIEW sub-menu, Press UP and DOWN to scroll through the

list of values. Press and hold to scroll through more quickly.

Select 2) Delete Last and press ENTER. Choose Yes and the

tester will delete the last saved record and return to the Memory

menu. If you selected 3) Delete All and press ENTER, choose Yes

to remove all stored records. The unit will automatically return to

the memory menu after the selection.

To upload all the values to the PC software program, highlight

UPLOAD ALL and press the ENTER key.

3) CALIBRATION: The calibration feature is used by service tech-

nicians for calibrating the tester. Proper equipment is required to

perform this task. Contact Nidec-Shimpo or your dealer for ad-

ditional details.

4) DIAGNOSTIC: This diagnostic feature is used to check status

of the load cell. If you suspect that your load cell transducer has

sustained an overload, it is possible to check the status. Place the

tester horizontally on the flat level surface and select “DIAGNOS-

TIC” in the main menu.

Figure 8: Diagnostic Menu

If the % offset is between 5% - 10 % please contact Nidec-Shimpo

or your supplier to arrange for a proper calibration.

If the % offset is greater than 10% the unit is possibly damaged

and needs repair or replacement.

These values are given as an indication only. The need for calibra-

tion or repair may vary according to the individual characteristics

of the load cell.

5) ABOUT: The ABOUT sub-menu displays the information of

your unit such as Firmware revision, Model, Capacity and Serial

number.

Figure 9: About Menu

MOUNTING: For proper operation and safety, it is necessary to

mount the torque tester with ranges of 25 N-m and higher. Fasten

the integral mounting bracket properly with 4 bolts and nuts to a

secure work surface. Mounting may be vertical or horizontal. For

lower torque ranges, this mounting bracket adapter is available

as an accessory if securing to a work surface is desired. To install

the bracket to the back of the unit, remove the four outer screws

with rubber feet. Disguard the rubber feet. Line up the adapter

plate’s four holes with the four outer threaded inserts on the bot-

tom of the TT. Attach the adapter bracket with the four screws that

were previously removed. Tighten securely. Line up the adapter

plate’s four holes with the four outer threaded inserts on the bot-

tom of the TT.

5

Load

Time

“UPPER” LED on

“OK” LED on

Upper Level

Load

Time

“OK” LED on

“LOWER” LED on

Lower Level

Load

Time

“UPPER” LED on

“LOWER” LED on

Lower Level

Upper Level

“OK” LED on

MEMORY MENU

1) VIEW

2) DELETE LAST

3) DELETE ALL

4) UPLOAD ALL

DIAGNOSTIC

OVERLOAD COUNT: 2

ORG. OFFSET: +0.4%

CUR. OFFSET: +0.4%

A total of overload count

% offset from the

prior calibration

Current % offset

ABOUT

FIRMWARE REV.: 1.00

MODEL: TT

CAPACITY: 10 N.M

S/N: 05130001