Opera, Control p, Control p control panel anel anel anel anel – SHIMPO DT-205L-S12 User Manual

Page 2

INSTRUMENTS

INSTRUMENTS

INSTRUMENTS

INSTRUMENTS

INSTRUMENTS

1701 Glenlake Avenue Itasca, IL 60143 · phone: (800) 237-7079 · fax: (630) 924-0342 · www.shimpoinst.com

OPERA

OPERA

OPERA

OPERA

OPERATING PROCEDURES

TING PROCEDURES

TING PROCEDURES

TING PROCEDURES

TING PROCEDURES

Non-Contact Measurement

1. Place a small piece of reflective tape

(included) on the shaft or moving

element (disc, pulley, etc.) whose

speed is to be measured. If the

element's surface is highly reflective

it may need to be painted a darker

color in order to ensure reliable

results. If the distance to the object

is less than 5" (127 mm), reflective tabs (optional) should

be used instead of reflective tape.

2. Aim the tachometer at the reflective tape from a distance

of 5" (127 mm) to 14' (4.3 m).

3. Press and hold the power switch for several seconds

(

when power button is depressed, laser is

active) to observe the display as it changes according

to the speed of the shaft or rotating element (as soon as

the laser hits the reflective tape, the unit will start to

indicate the speed). If the beam is “on target” the RPM

indicator will be flashing.

4. After observation is completed, retain the reading by

releasing the power switch (to turn off laser) before

removing the tachometer from its position. The last

reading is displayed for a period of 5 minutes and can be

extended any number of additional 5 minute increments

by pressing the memory switch.

NOTE: When switching from the contact to the non-contact mode,

the unit RPM will show on the display and also 5 dashes (-----).

Press the power switch to cancel the dashes.

Contact Measurement

For both RPM measurements and non-RPM

measurements, screw the 200L Adapter

(included) into the front of the tachometer.

NOTE: Hand tightening is sufficient; do not

use excessive torque when mounting

RPM Measurement

1. Place rubber cone tip on the shaft of

the 200L adapter. Make certain that

the pin on the shaft is properly

aligned with the slot on the cone’s

sleeve.

2. Bring cone into contact with the

shaft. Apply only enough pressure

to avoid slippage.

3. Press and hold the power switch. During engagement

the display will reflect the proper RPM while the unit RPM

will be flashing above the display digits.

4. Release the power switch prior to removal of tachometer

from rotating object to capture the last reading.

5. After release of the power switch, the last reading (with

a non-flashing RPM unit) will remain on the display and

in memory for 5 minutes, and can be extended any

number of additional 5 minute periods by pressing the

memory switch.

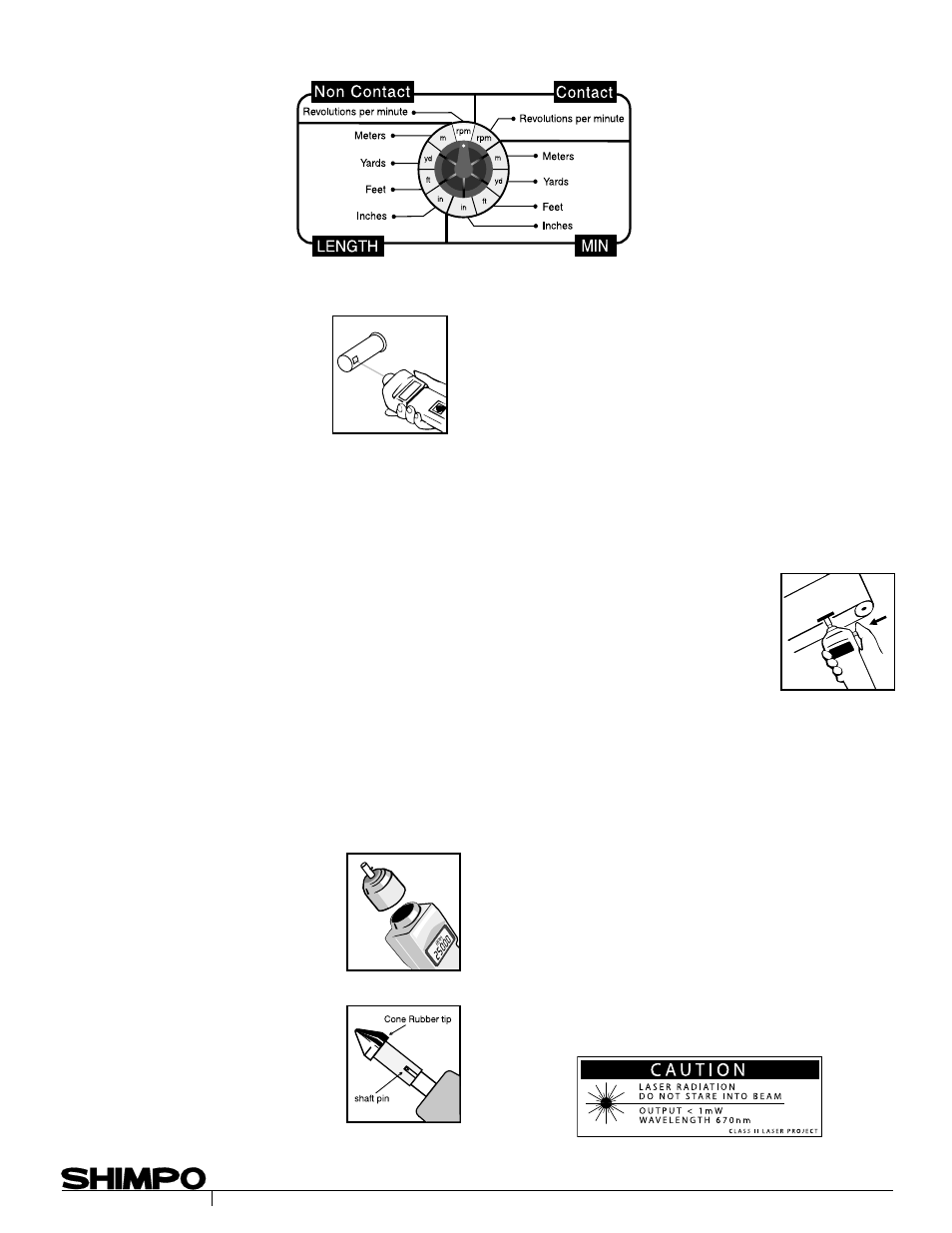

Rate & Length Measurement

1. Attach the master wheel and select the desired function

using the selector switch located just below the LCD

display.

2. Press and hold the power switch;

while the wheel is turning and the

tachometer is measuring the selected

function, the function will be

indicated, and the unit of measure

function will be flashing.

3. Release the power switch before

disengaging the tachometer in order to capture the last

reading.

4. After release of the power switch, the last, maximum,

and minimum readings will be stored in memory for 5

minutes and can be extended any number of additional

5 minute periods by pressing the memory button.

NOTE: The memory will clear in 5 minutes after the release of

the power switch.

For steps 1-4 described above, it was assumed that the selector

switch was in the rate mode region. If the selector switch is

moved from the rate mode to the count mode (length), the

display will show the selected function (m, ft, yd, or in) and also

5 dashes (-----). Press the power switch to cancel the dashes

and start measuring the same way as was described above. Once

in the counting mode, the measurement can be stopped at any

time and the last reading will be retained for 5 minutes. There is

no maximum or minimum reading when in the count (length)

mode.

CONTROL P

CONTROL P

CONTROL P

CONTROL P

CONTROL PANEL

ANEL

ANEL

ANEL

ANEL

2