Configurable parameters, 7 maintenance, 8 troubleshooting – Pyromation Series 442 User Manual

Page 9

Copyright 2006 Pyromation, Inc., All rights reserved.

9 of 11

Phone (260) 484-2580

•

FAX (260) 482-6805 or (800) 837-6805

•

www.pyromation.com

442-D

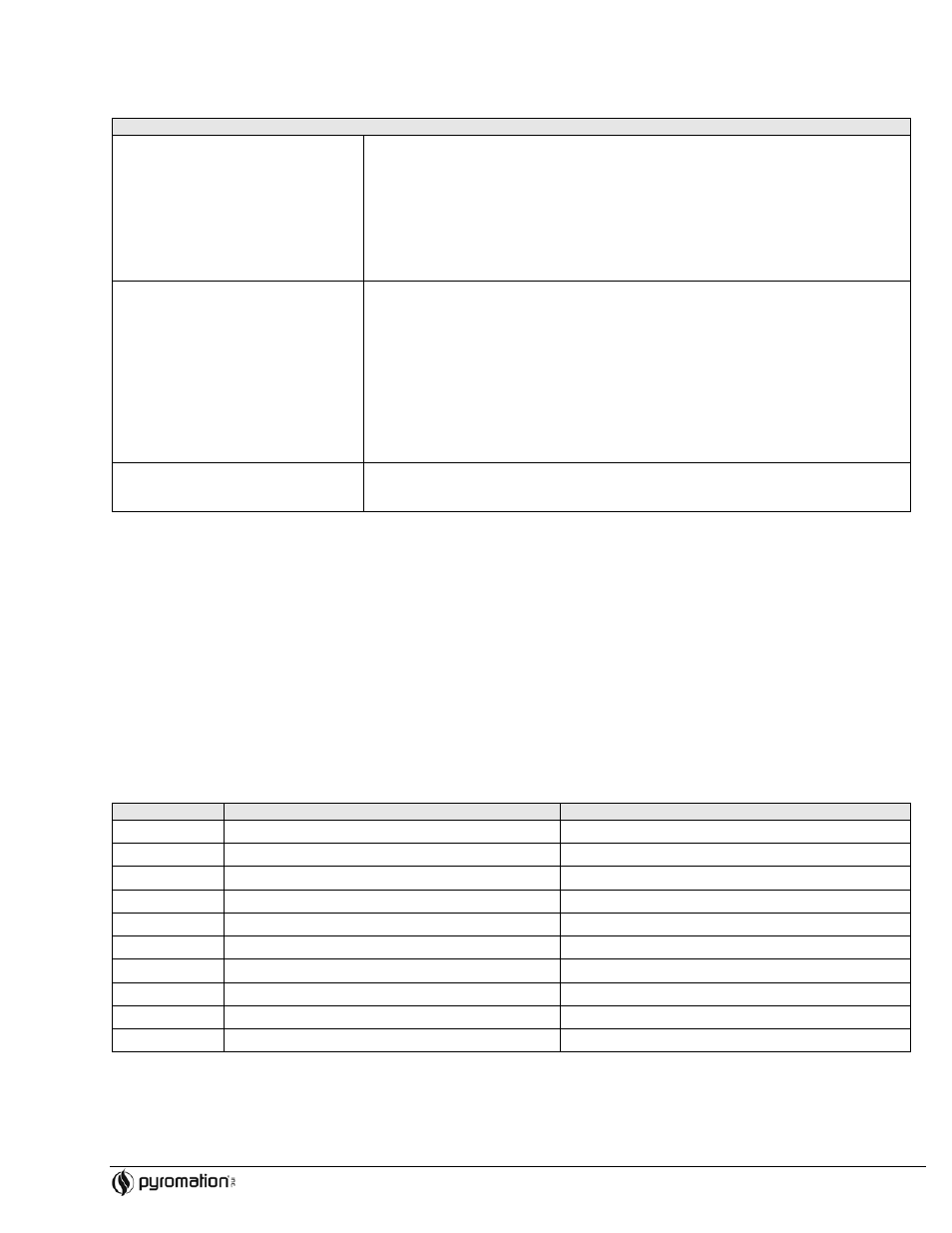

6.7 Configuration using HART

protocol and TransComm

The configuration of the head transmitter can be done using both the HART

protocol and the TransComm software. The following

table shows the structure of the interactive menu led operation of TransComm.

Configurable parameters

Standard settings

• Sensor type

• Connection mode (2, 3 or 4 wire connection)

• Units (°C or °F)

• Measurement range start (depends on sensor)

• Measurement range end (depends on sensor)

• Coefficient X0 to X4 (on sensor type Polynom RTD/TC)

• Temperature-compensation (on sensor type Polynom TC)

Expanded settings

• Cold junction compensation (internal/external on TC connection)

• Temperature external (on TC with cold junction compensation external)

• Compensation resistance (0 to 20)

Ω on 2 wire connection

• Fault condition reaction (

≤ 3.6 mA or ≥ 21.0 mA)

• Output (analog standard/inverse)

• Damping (0 to 8) s

• Offset (-9.9 to +9.9)

°C [-17.8 to +17.8] °F

• TAG (Measurement point identification)

• Identifier (Descriptor)

Service functions

• Simulation (on/off)

For detailed TransComm operating instructions please read the online documentation contained in the software.

6.8 Interactive setting up of the temperature transmitter

Customer specific linearization and sensor matching is done using the TransComm configuration software. The program

calculates the linearization coefficients X0 to X4 that need to be entered into the PC configuration software.

7 MAINTENANCE

The head transmitter is maintenance free.

8 TROUBLESHOOTING

Always start troubleshooting with the checklists below if faults occur after start up or during operation. This takes you directly (via

various queries) to the cause of the problem and the appropriate remedial measures. Note: Due to its design, the device cannot

be repaired. However, it is possible to send the device in for examination.

8.1 Application fault message

Application fault messages are shown in the display of the HART

hand operating module “DXR275/375” once the menu point

“ERROR CODE” has been selected.

Fault code

Cause

Action/cure

0

No fault, Warning

None

10

Hardware fault (unit defective)

Replace head transmitter

11

Sensor short circuit

Check sensor

12

Sensor cable open circuit

Check sensor

13

Reference measurement point defective

None

14

Unit not calibrated

Return head transmitter to manufacturer

106

Up/Download active

None (will be automatically acknowledged)

201

Warning: Measured value too small

Enter other values for measured value range start

202

Warning: Measured value too large

Enter other values for measured range end

203

Unit is reset (to factory default settings)

None