Cleaning the reflectors – Precision Control Systems ExtrudeIR 4069E User Manual

Page 23

Model 4069E ExtrudeIR

TM

Instruction Manual

Dimensions and Specifications

Research, Inc.

Page 19 of 26

CLEANING THE

REFLECTORS

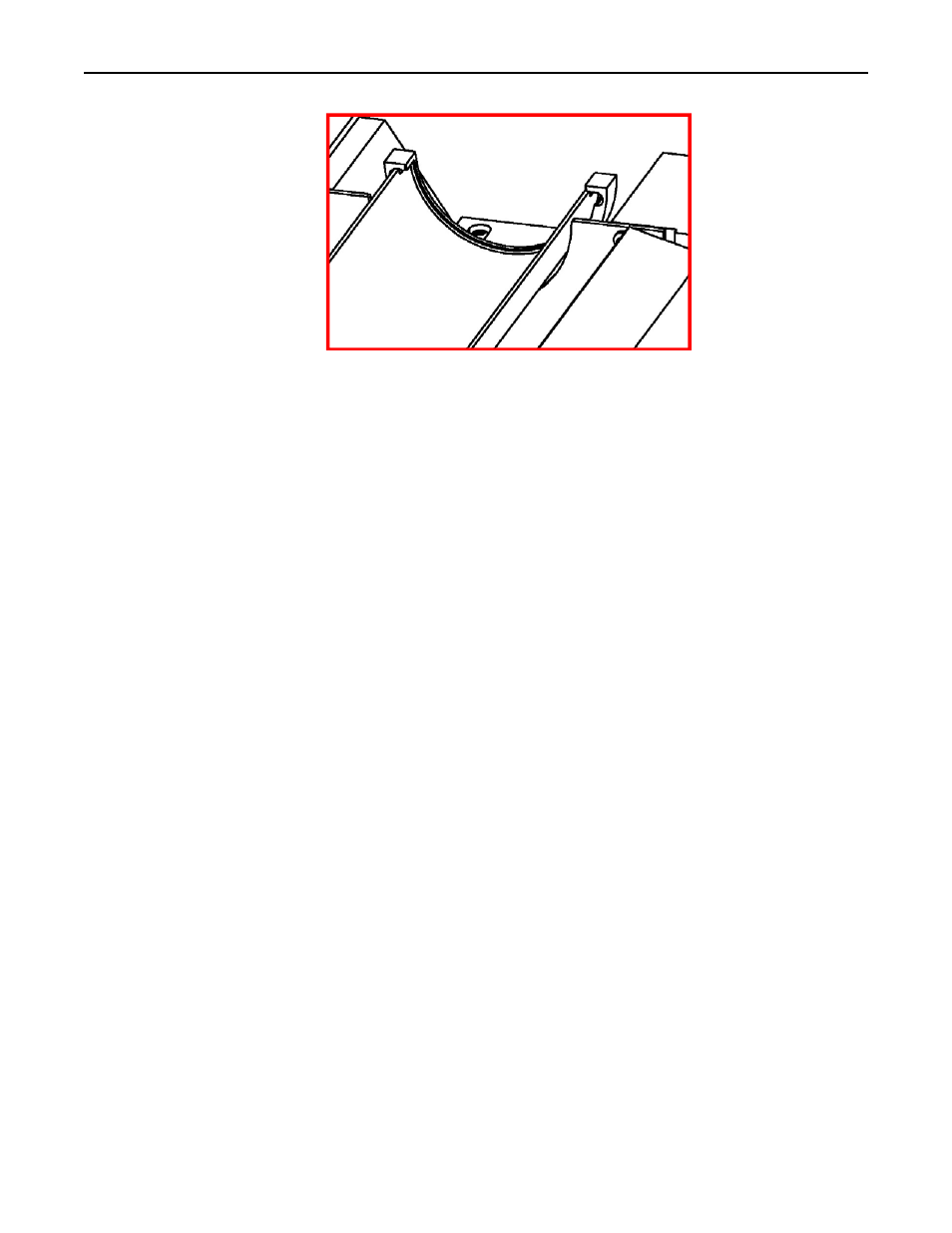

Figure 9

5. If cleaning the liner, use a non-abrasive glass cleaner (i.e. household ammonia

and water or isopropyl alcohol) and a clean, dry, lint-free cloth. After

cleaning, do not touch the outside surface of the liner unless wearing cotton

gloves.

6. Reinsert the edges of the liner into the grooves of the quartz-liner bracket.

7. Reinstall the other bracket and secure with the two bracket screws.

8. Repeat this process for the other half of the liner.

Clean reflectors provide the greatest radiant efficiency. If the reflector surface becomes

contaminated, it reflects less energy. The energy that is not reflected is lost, absorbed

by the reflectors, and removed by the cooling water and air.

The following procedure should be used to clean the Model 4069 reflectors:

1. Remove the lamps and quartz liner as described in Lamp

Removal/Replacement/Installation and Split Quartz Liner Cleaning and

Replacement.

2. Clean the reflectors with a mixture of warm water and common household

ammonia followed by a thorough wipe-down using a clean, water-dampened

flannel cloth.

3. Depending on the type of contamination present on the reflector, a suitable

solvent may be required to remove the contamination. The solvent must be

selected based on its inability to adversely affect the aluminum reflector.

4. Thoroughly wipe the reflector using the warm water/household ammonia

mixture followed by the dampened flannel cloth.

5.

Replace the lamps and quartz liner, as outlined in Lamp

Removal/Replacement/Installation and Section Split Quartz Liner Cleaning

and Replacement.

If necessary, the reflectors may require re-polishing. This is permissible because the

reflector is solid aluminum and can be re-polished many times without damage from

continued erosion. A fine particle polishing compound, such as a chrome, semi-

chrome, or soft metal polishing compound may be used. These types of compounds

can be found at a local automotive or metal-polishing supply house. Follow the

polishing instructions listed on the polishing product.