KROHNE ECOFLUX IFS 1000 EN User Manual

Page 7

7

5

Installation in the pipeline

•

Installation material, refer to table on page 3.

•

Pipe flanges and operating pressure,

refer to table on page 3.

•

Pipe flange spacing (fitting dimension)

1)

Dimensions including grounding rings

2)

No gasket required between measuring tube and pipe flanges, seal provided

by PFA liner on the flanges

s

Thickness of gasket D2 between grounding rings and pipe flanges, not

included with flowmeter, to be provided by customer. Use Teflon-type gaskets,

deformable under pressure, to DIN 2690/ANSI B 16.21,

8 - 16 N/mm

2

/1160 - 2320 psi.

•

High-temperature pipelines

Where process temperatures exceed 100 °C/212 °F, provide for facilities to

compensate for longitudinal expansion on heat-up of the pipeline.

For short pipelines use resilient gaskets and

for long pipelines install flexible pipe elements (e.g. elbows).

•

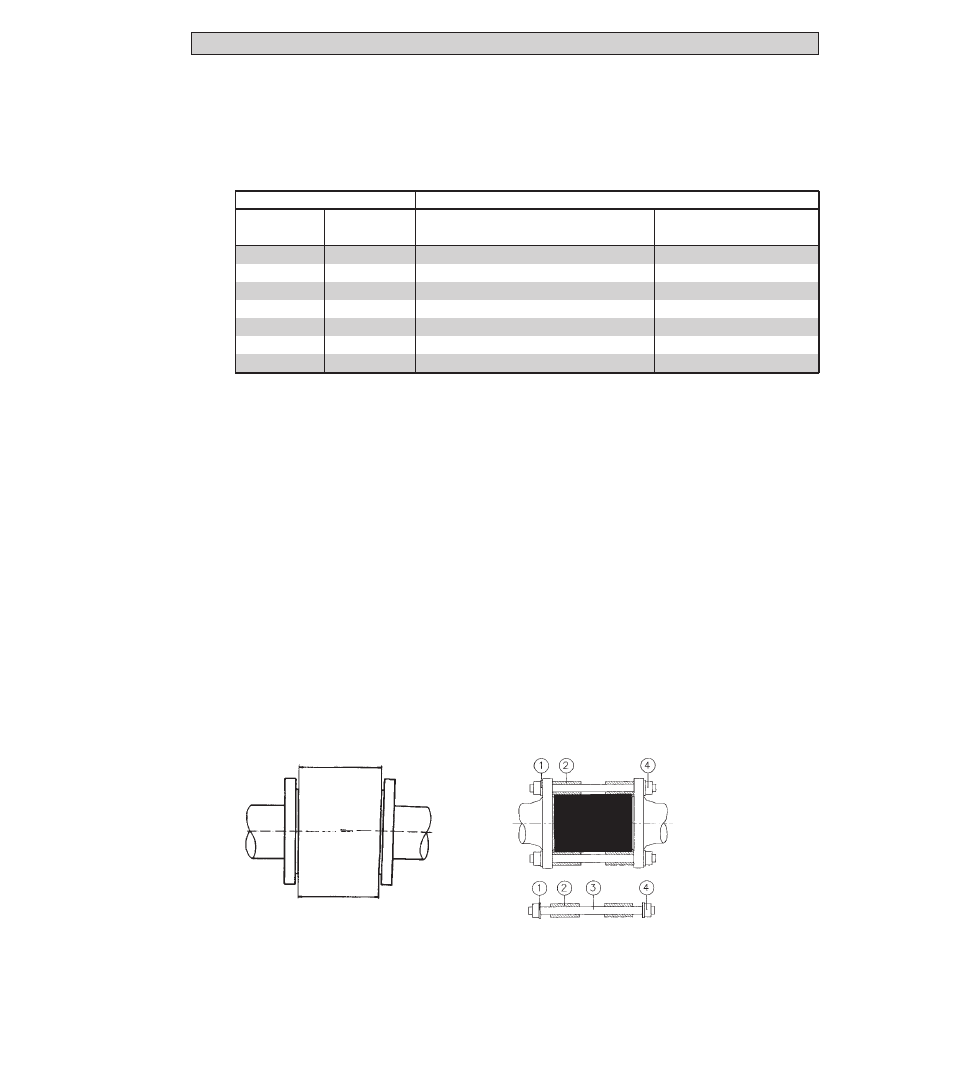

Position of flanges

• Arrangement of centering sleeves

Install flowmeter in line with the pipe

1 washer

axis. Pipe flange faces must be

2 centering sleeve

parallel to each other,

3 stud bolt

max. permissible deviation:

4 hex. nut

L

max

- L

min

≤

0,5 mm

≤

0.02”

L

max

L

min

Nominal size to . . .

Space between pipe flanges

DIN 2501

ANSI

Installation with

Installation without

and JIS

B 16.5

grounding rings 1)

grounding rings 2)

DN 10, 15

3

/

8

”,

1

/

2

”

2 x s + 68 mm

(2 x s + 2.68”)

–

–

DN 25

1

2 x s + 60 mm

(2 x s + 2.38”)

54 mm

(2.13”)

DN

40

1

1

/

2

”

2 x s + 84 mm

(2 x s + 3.31”)

78 mm

(3.07”)

DN

50

2

2 x s + 106 mm

(2 x s + 4.17”)

100 mm

(3.94”)

DN 80

3

2 x s + 156 mm

(2 x s + 6.14“)

150 mm

(5.91”)

DN 100

4

2 x s + 206 mm

(2 x s + 8.11”)

200 mm

(7.87”)

DN 150

6

2 x s + 206 mm

(2 x s + 8.11”)

200 mm

(7.87”)