KROHNE ECOFLUX IFS 1000 EN User Manual

Page 5

5

•

Strong electromagnetic fields, avoid in vicinity of flowmeter.

•

Straight inlet run minimum of 5

××

DN and outlet run minimum of 2

××

DN,

(DN = meter size), measured from the electrode axis.

•

Vortex and corkscrew flow: increase length of inlet and outlet runs or install

flow conditioners.

•

Mixing different process liquids: install flowmeter upstream of mixing point or at an

adequate distance downstream (minimum of 30 x DN), otherwise display may be unsteady.

•

Plastic pipes and internally coated metal pipelines: grounding rings required,

see Section 7 ”Grounding”.

•

Insulated pipeline: do not insulate flowmeter.

•

Zero setting not necessary. To check, it should be possible to set ”zero” flow velocity

in the completely filled measuring tube. Shutoff valves should therefore be provided either

downsteam of the flowmeter or upsteam and downstream of the flowmeter.

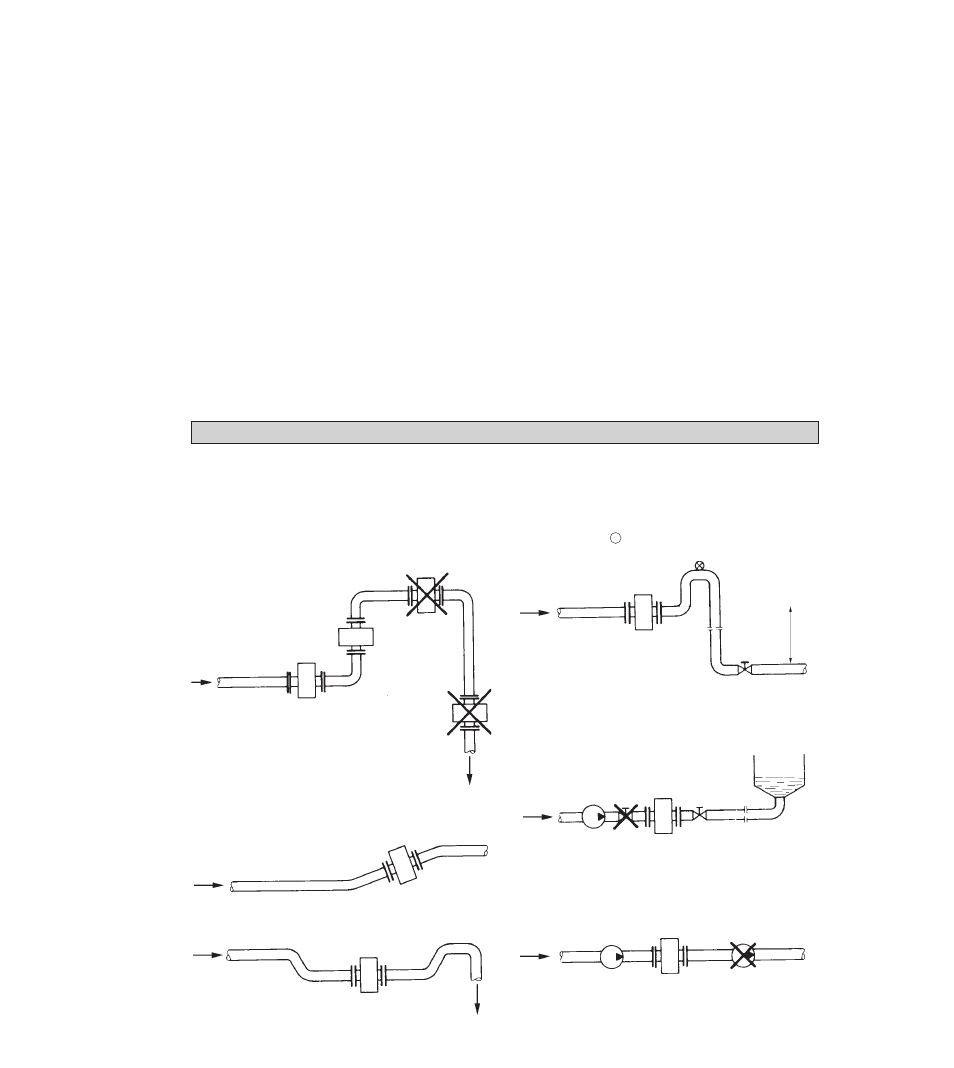

Highest point of pipe run

(Air bubbles collect in measuring

tube - faulty measurements!)

Preferred

locations

Downpipe

”Zero” flow

velocity.

Line drained.

Faulty

measurements!

Horizontal pipe run

Install in slightly ascending pipe section. If not

possible, assure adequate velocity to prevent air,

gas or vapor from collecting in

upper part of flow tube.

Open feed or discharge

Install meter in low section of pipe.

open discharge

Long pipeline

Always install control and shutoff valves

downstream of flowmeter.

Pumps

Never install flowmeter on pump suction side.

> 5m

> 16 ft

2 Suggestions for installation

To avoid measuring errors due to gas/air inclusion or to pipe runing empty please observe the

following:

Downpipe over 5 m (16 ft) length

Install air valve X downstream of

flowmeter.