Service, Service 6.1 maintenance – KROHNE DK 32 Purge EN User Manual

Page 18

6

SERVICE

18

DK32

www.krohne.com

04/2011 - 4000898801 MA DK32 Air purge set R02 en

Service

6.1 Maintenance

Within the scope of routine maintenance of the system and pipelines, the flowmeter should also

be inspected for signs of fouling, corrosion, mechanical wear and leaks, as well as damage to

the measuring tube and indicator.

We advise that inspections be carried out at least once a year.

The device must be removed from the piping before cleaning.

CAUTION!

Pressurized pipes must be depressurized before removing the device.

In the case of flowmeters used for measuring aggressive or hazardous products, appropriate

safety precautions must be taken with regard to residual liquids in the measuring section.

Always use new gaskets when reinstalling the flowmeter in the pipeline.

CAUTION!

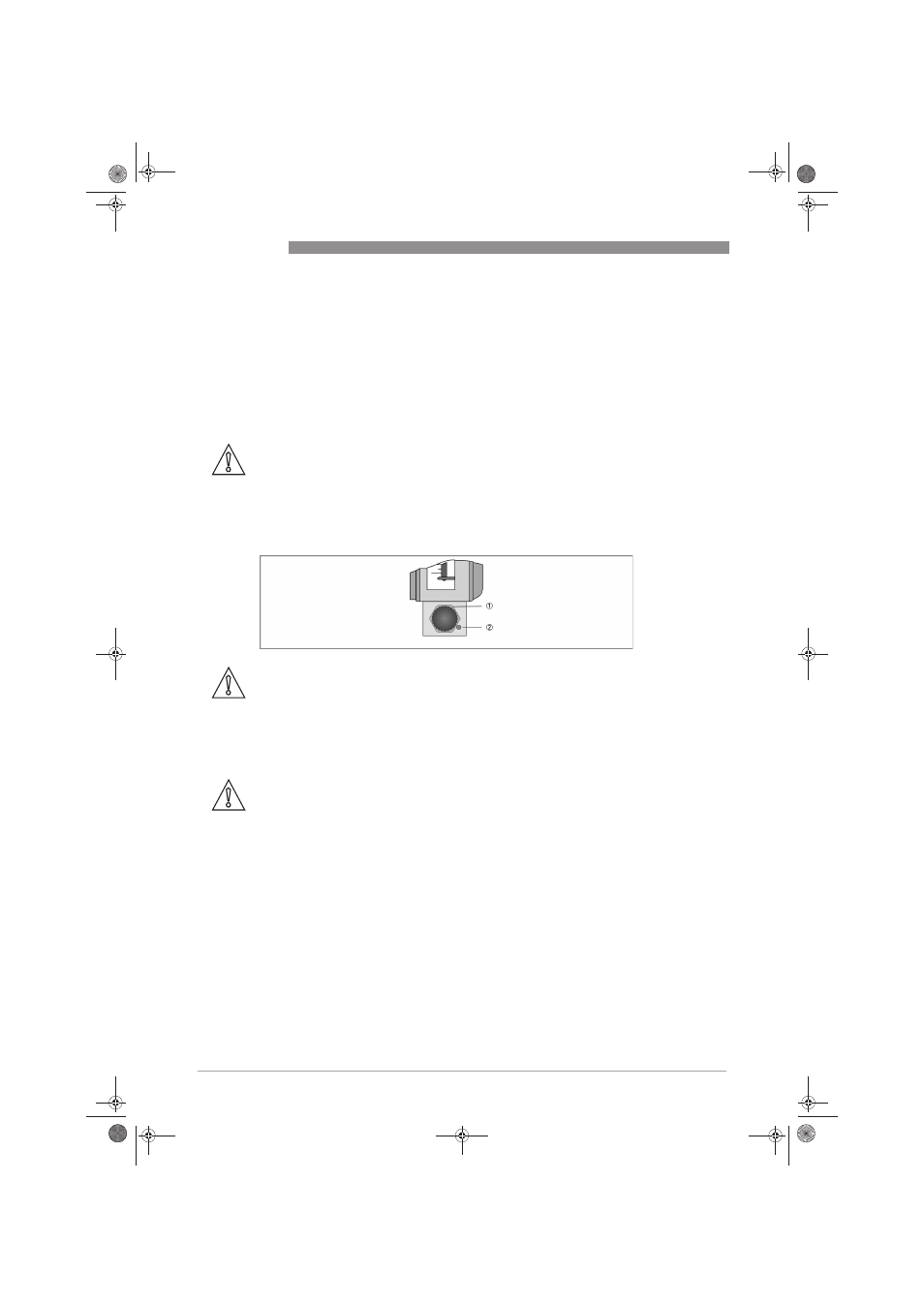

Under certain circumstances the valve packing gland may have to be adjusted during its service

life. This means that the union nut 1 has to be retightened. If necessary, press the retaining pin

2 against its internal spring.

Apply a tightening torque of not more than 5Nm.

CAUTION!

Valves that have not been actuated for a longer period of time may exhibit a higher initial

actuation torque.

MA_DK32_Purge_R02_en_898801_PRT.book Page 18 Wednesday, April 6, 2011 3:01 PM