Technical data – KROHNE OPTIFLUX 2000 EN User Manual

Page 31

TECHNICAL DATA

6

31

OPTIFLUX 2000

www.krohne.com

4/2014 - 4000839504 - HB OPTIFLUX 2000 R04 en

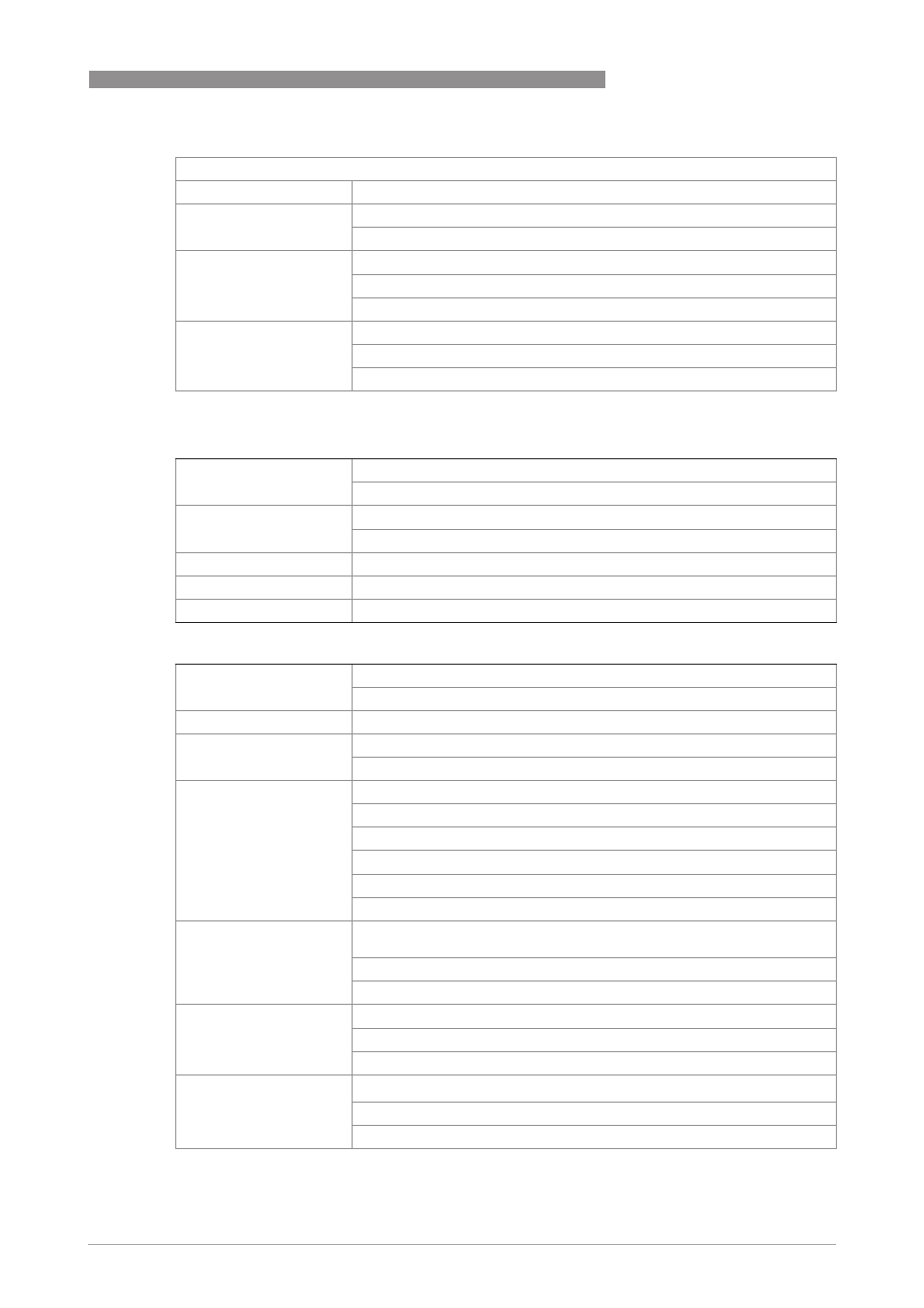

Chemical properties

Chemical properties

Chemical properties

Chemical properties

Physical condition

Electrically conductive liquids

Electrical conductivity

Standard: ≥ 5 µS/cm

Demineralized water: ≥ 20 µS/cm

Permissible gas content

(volume)

IFC 050: ≤ 3%

IFC 100: ≤ 3%

IFC 300: ≤ 5%

Permissible solid content

(volume)

IFC 050: ≤ 10%

IFC 100: ≤ 10%

IFC 300: ≤ 70%

Installation conditions

Installation

Assure that the flow sensor is always fully filled.

For detailed information refer to

Installation

on page 12.

Flow direction

Forward and reverse

Arrow on flow sensor indicates flow direction.

Inlet run

≥ 5 DN

Outlet run

≥ 2 DN

Dimensions and weights

For detailed information refer to

Dimensions and weights

on page 40.

Materials

Sensor housing

Sheet steel

Other materials on request

Measuring tube

Austenitic stainless steel

Flanges

Carbon steel

Other materials on request

Liner

Standard:

Standard:

Standard:

Standard:

DN25...150 / 1...6": polypropylene

DN200...3000 / 8...120": hard rubber

Option:

Option:

Option:

Option:

DN25...150 / 1...6": hard rubber

DN200...1000 / 8...40": polyolefin

Protective coating

On exterior of the meter: flanges, housing, signal converter (compact

version) and / or connection box (field version)

Standard: polyurethane coating

Option: subsoil coating, offshore coating

Connection box

Only for remote versions

Standard: die-cast aluminium

Option: stainless steel

Measuring electrodes

Standard: Hastelloy

®

C

Option: stainless steel, titanium

Other materials on request