Profibus settings, 3 menu c, setup – KROHNE MFC 300 Profibus User Manual

Page 35

PROFIBUS SETTINGS

5

35

MFC 300

www.krohne.com

07/2014 - 4001086802 - AD MFC 300 PROFIBUS R02 en

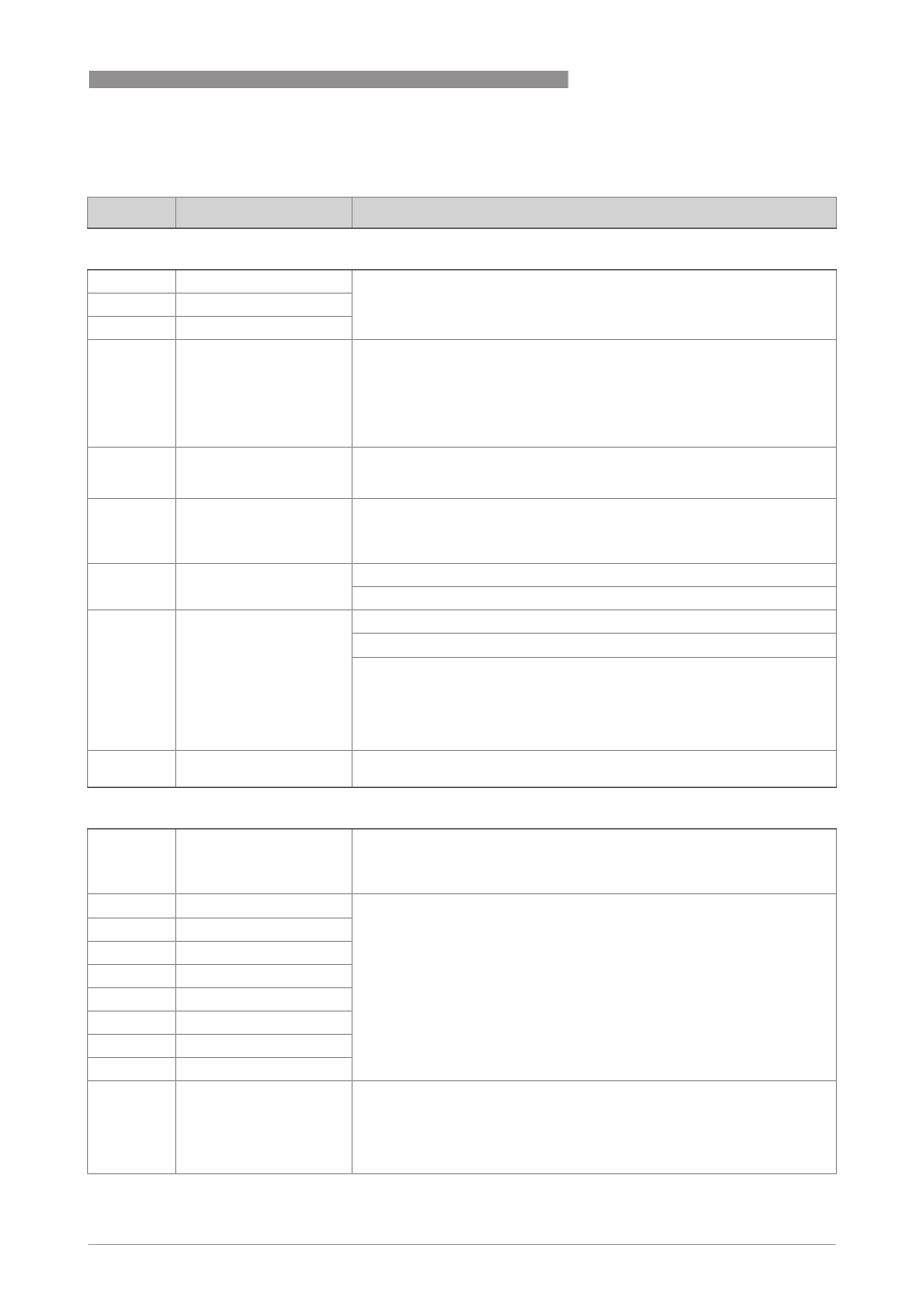

5.3 Menu C, Setup

No.

Function

Settings / descriptions

C4 I/O Totaliser

C4.1

FB4 Totaliser 1

Set function of Totaliser _

_ stands for 1, 2, 3 (= Totaliser 1, 2, 3)

C4.2

FB5 Totaliser 2

C4.3

FB6 Totaliser 3

C4._.1

Totaliser Function

Select:

Absolute Total (counts positive and negative values) /

Incremental Total (counts only the positive values) /

Decremental Total (counts only the negative values) /

Stop Totaliser (totaliser is stopped, no counting) /

All As Positive (neg. input will be multiplied with -1.0) /

All As Negative (pos. values will be multiplied with 1.0)

C4._.2

Measurement

Select:

Volume Flow / Mass Flow / Contentration Total 1 / Contentration Total 2 /

Conc. volume flow 1 / Conc. volume flow 2

C4._.3

Preset Value

Predefines a threshold (using high low limit value of the totaliser affected;

the THRESHOLD bit will be set in the long status information bytes of the

interface if the actual value of the totaliser is outside these limits. This can

be also used for a status output.

C4._.4

Reset Totaliser

The current value of the totaliser can be set to zero.

Select: No / Yes (reset totaliser 1…3)

C4._.5

Error Behaviour

Defines the behaviour of this function block in case of errors.

Select: hold meas. value / ignore error / stop totaliser

hold meas. value:

hold meas. value:

hold meas. value:

hold meas. value: Totalization is continued based on the last incoming value

with good status before the first occurrence of bad status.

ignore error:

ignore error:

ignore error:

ignore error: Totalization is continued using the input values despite the bad

status. The status is ignored.

stop totaliser:

stop totaliser:

stop totaliser:

stop totaliser: Totalization is stopped during occurrence of bad status of

incoming values.

C4._.6

Information

Serial no. of the I/O board, software version no. and production date of the

circuit board will be displayed

C5 I/O PROFIBUS

C5

I/O PROFIBUS

Using the menu functions mentioned below you will be able to control

basically the five analog input blocks of this PROFIBUS device. These eights

menus are identical so they are grouped together and their functions are

described in one go.

C5.1

FB1 Analog Inp.

There are 8 analog input blocks.

_ stands for the 8 analog input blocks: FB1 (_ = 1), FB2 (_ = 2), FB3 (_ = 3),

FB7 (_ = 4), FB8 (_ = 5), FB9 (_ = 6), FB10 (_ = 7), FB11 (_ = 8),

C5.2

FB2 Analog Inp.

C5.3

FB3 Analog Inp.

C5.4

FB7 Analog Inp.

C5.5

FB8 Analog Inp.

C5.6

FB9 Analog Inp.

C5.7

FB10 Analog Inp.

C5.8

FB11 Analog Inp.

C5._.1

Measurement

Select measurement for the analog input blocks:

Mass Flow / Density / Temperature / Concentration 1 / Concentration 2 /

Conc. mass flow 1 / Conc. mass flow 2 / Conc. volume flow 1 / Conc. volume

flow 2 / Sensor Deviation / Sensor Average / Drive Energy / Tube Frequency /

Tube Strain / Inner Cylinder Strain / Flow Velocity / Volume Flow /

Electronics Temperature / Supply