Connections, Iv — operation, Controls and indicators – KEPCO EL Series Quick Start Guide (Firmware Version 4.00 and higher) User Manual

Page 2: Startup, Table 1. front panel functions, Set setpoint adjustment resolution

2

228-1687 REV 4

071913

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11355 U.S.A. " TEL (718) 461-7000 " FAX (718) 767-1102

http://www.kepcopower.com " email: [email protected]

CAUTION: Refer to the Operator’s manual for optional

slide installation. Failure to use slide and screws

specified will damage the unit and void the warranty.

CONNECTIONS. See Figure 3 for typical test connec-

tions. The Series EL is capable of drawing very high cur-

rents. Connections between the UUT and the Series EL

must be properly sized to carry the maximum current.

Additionally, it is extremely important to ensure all connec-

tions are tight and corrosion free. See Section II, Safety

Warnings. Use low resistance hardware supplied with the

unit for connections to ± LOAD terminals. Regular inspec-

tion of ±LOAD connection tightness is important.

Connect the Series EL to the UUT using cabling

appropriate for the current expected during testing.

CAUTION: Ensure polarity is correct - reversed

polarity will cause immediate and significant damage

to the Series EL and/or the UUT. Contact Kepco if

assistance is needed in selecting the appropriate wire

size, length and physical configuration. Ensure all

connectors are suitable for the current and voltage

expected and that connections are tight. Connections

should be re-checked to ensure continued low-resistance

connections on a regular basis. CAUTION: When

connecting the Series EL to the UUT be very careful

not to accidentally short the UUT output while

connecting the wiring. Best practice is to make the

connection to the UUT Positive (+) output connector

the last connection.

Refer to the EL Operator manual for connections required

for remote control.

IV — OPERATION

Operation is either from the front panel (local) or via com-

puter control (remote). For remote operation, refer to the

EL Operator manual.

CONTROLS AND INDICATORS. Figure 2 shows the

location of front panel components described in Table 1.

STARTUP.

1. After all connections are completed, turn on system by

setting ON/OFF switch to ON.

2. After warming up for about 15 seconds, the unit begins

the power-up self-test.

3. Set the desired Mode (see steps 1 and 2 of “Changing

4. When ready, the LOAD switch-indicator lights green.

The VOLTS display shows the voltage of the source

under test. AMPS and KW displays indicate zero.

SET SETPOINT ADJUSTMENT RESOLUTION.

1. Momentarily press the CONTROL knob a number of

times to select the digit representing the resolution

needed for adjustment during test (selected digit

blinks).

2. For example, if 1A per click of adjustment is desired,

select the most significant digit (MSD), which yields 1

Amp per click. If finer resolution is desired, select a

less significant digit such as 100mA or 10mA per click

(see Figure 1). NOTE: Leading zeroes are sup-

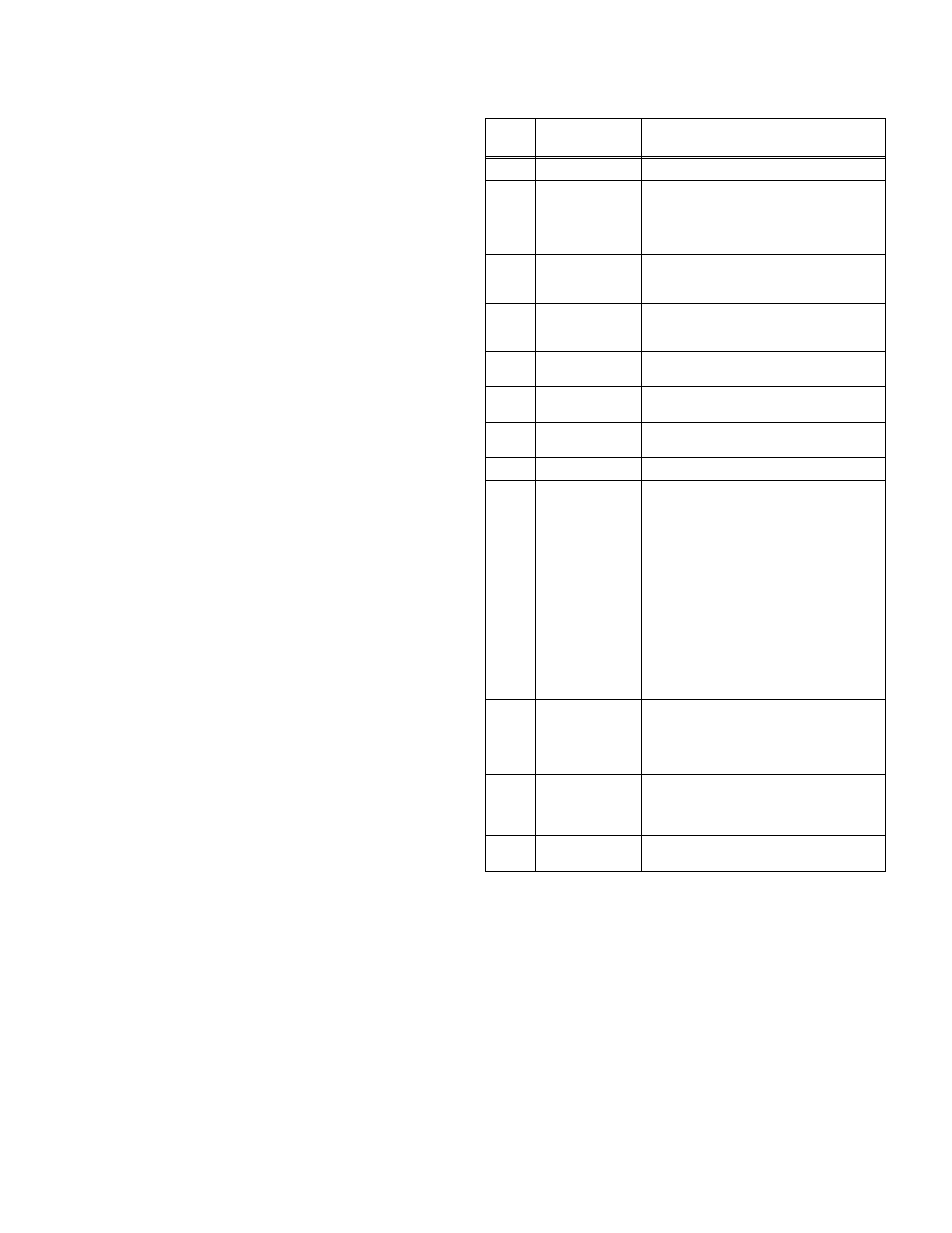

TABLE 1. FRONT PANEL FUNCTIONS

SEE

FIG. 1

COMPONENT

FUNCTION

1

AMPS display

Displays the load test current in Amps

2

CR indicator

On (solid) indicates Constant Resistance

Mode; factory default set to 1000 Ohms. On

(blinking) indicates Constant Conductance

Mode; factory default set to 1mS (0.001

siemens, I/E).

3

CI indicator

On to indicate Constant Current Mode

(factory default setpoint: 0A. After use, the

last used setpoint is retained).

4

CV indicator

On to indicate Constant Voltage Mode

(factory default setpoint: maximum load

voltage).

5

CP indicator

On to indicate Constant Power Mode (factory

default setpoint: 0 kilowatts).

6

Power ON/OFF

switch

Rocker switch: press top half to turn power

on, bottom half to turn power off.

7

LAN indicator

On indicates optional LAN connection is

active.

8

LOCAL indicator

On indicates Local mode is active.

9

CONTROL

rotary control/

pushbutton switch

When LOCAL is active, three functions are

available as follows:

a. Select Mode: Press, hold (at least 3

seconds) and rotate knob to select mode

indicated by the CI, CR, CV and CP

indicators (see Table 2).

b. Set Value: Rotate knob to adjust the level

of the controlled parameter: current, voltage,

resistance, conductance or power (see Table

3). Rotate clockwise to increase,

counterclockwise to decrease. Settings are

stored and will be available at next power-up.

c. Select Digit: Momentarily press knob to

select one digit (blinks). Convenience

function allows adjustment of one digit at a

time.

10

LOAD

pushbutton

switch/indicator

Indicator lights to show load status: green

(ready to operate), amber (load is engaged)

or blinking red (fault condition exists). Press

switch to engage/disengage load or clear

fault indication.

11

KW display

Displays the power (Amps x Volts) being

dissipated by the load in kilowatts. Also

momentarily indicates resistance (in Ohms)

or conductance (in Siemens) setting.

12

VOLTS display

Displays test voltage from UUT applied to the

load in Volts.