3 field wiring table (4-20 ma output), 4 sensor location, Field wiring table (4-20 ma output) – Detcon DM-200 User Manual

Page 10: Sensor location

Model DM-200

DM-200 Instruction Manual

Rev. 2.0

Page 6 of 40

advisable to calibrate with interference gases. They should be used only as a guide.

2.3 Field Wiring Table (4-20 mA output)

Detcon UniTox™ toxic gas sensor assemblies require two-conductor connections between power supplies and

host electronic controllers. Wiring designators are + (DC), and – (DC). Maximum single conductor resistance

between sensor and controller is 10 ohms. Maximum wire size for termination in the sensor assembly terminal

board is 14 gauge.

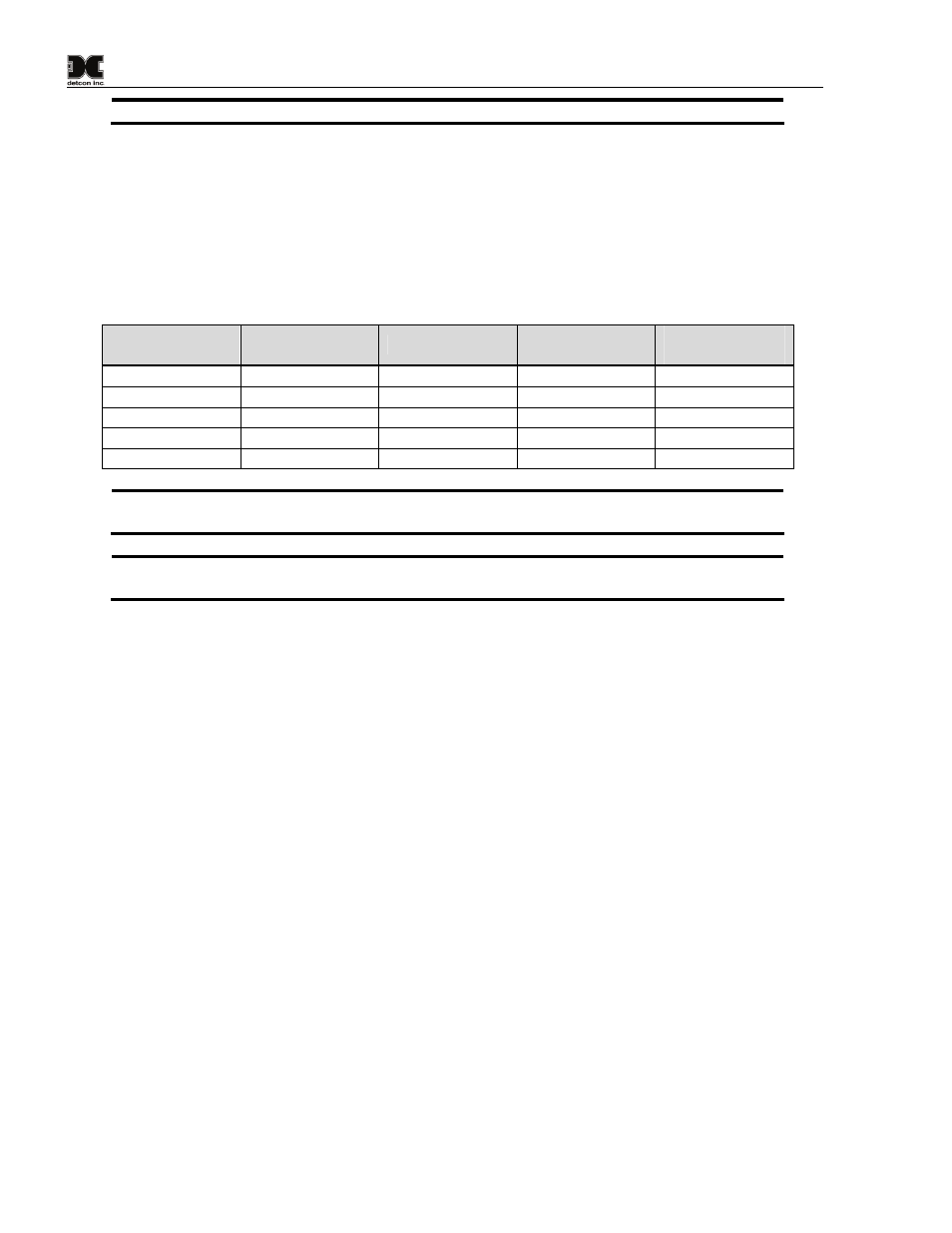

Table 1 Wire Gauge vs. Distance

AWG

Wire Dia.

Meters

Feet

Over-Current

Protection

22 0.723mm 700 2080 3A

20 0.812mm 1120 3350 5A

18 1.024mm

1750

5250

7A

16 1.291mm 2800 8400 10A

14 1.628mm 4480 13,440 20A

NOTE: This wiring table is based on stranded tinned copper wire and is designed to serve as a

reference only.

NOTE: Shielded cable may be required in installations where cable trays or conduit runs

include high voltage lines or other sources of induced interference.

2.4 Sensor Location

Selection of sensor location is critical to the overall safe performance of the product. Five factors play an

important role in selection of sensor locations:

(1) Density of the gas to be detected

(2) Most probable leak sources within the industrial process

(3) Ventilation or prevailing wind conditions

(4) Personnel exposure

(5) Maintenance access

Density - Placement of sensors relative to the density of the target gas is such that sensors for the detection of

heavier than air gases should be located within 2-4 feet of grade as these heavy gases will tend to settle in low

lying areas. For gases lighter than air, sensor placement should be 4-8 feet above grade in open areas or in

pitched areas of enclosed spaces.

Leak Sources - Most probable leak sources within an industrial process include flanges, valves, and tubing

connections of the sealed type where seals may either fail or wear. Other leak sources are best determined by

facility engineers with experience in similar processes.

Ventilation - Normal ventilation or prevailing wind conditions can dictate efficient location of gas sensors in a

manner where the migration of gas clouds is quickly detected.

Personnel Exposure - The undetected migration of gas clouds should not be allowed to approach concentrated

personnel areas such as control rooms, maintenance or warehouse buildings. A more general and applicable

thought toward selecting sensor location is combining leak source and perimeter protection in the best possible

configuration.