Roubleshooting – COSA Xentaur COSA 9610 User Manual

Page 39

INSTALLATION, OPERATION AND MAINTENANCE MANUAL – COSA 9610™

Page 39 of 44

4.4.

T

ROUBLESHOOTING

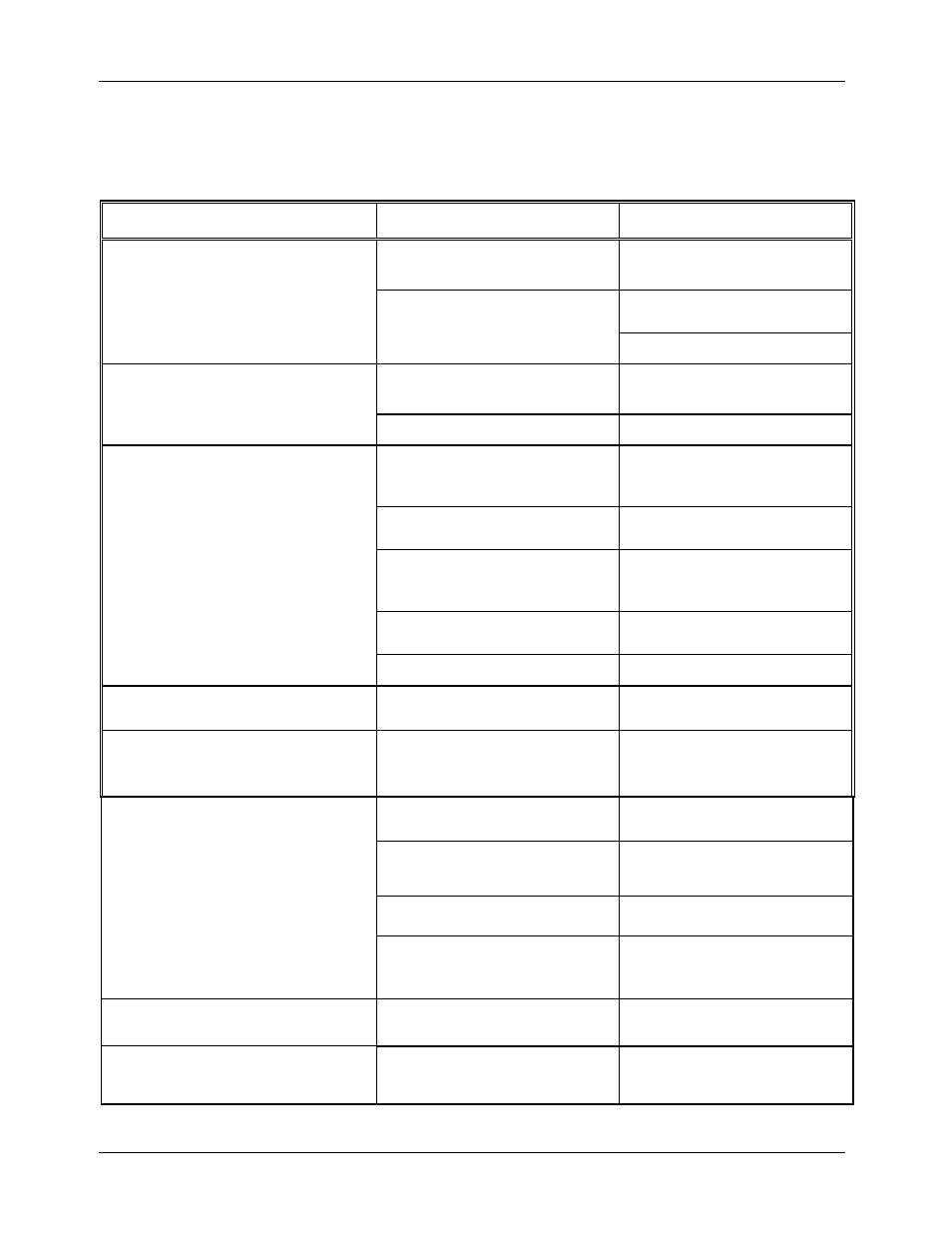

Breakdown -> fault report

Test

Action

No air pressure ->

flow alarm

tube fracture

Replace tube

Measuring

pressure

behind

reducing valve

Open valve for reducing valve

tagged “air supply”

Increase output pressure

No gas pressure -> flow alarm

Tube fracture

Close main valve immediately

and replace pipe

Blockage in gas supply

Check/clean/replace tubing

Oven temperature below 750°C ->

temp low alarm

Check set point on temp.

Controller. Check fuse 1 in TB1

of regulated supply

Reset

Check fuse 4 in TB4 of temp.

controller (display is off)

Replace

Check output voltage temp.

controller (0-5 VDC) to Solid

State Relay

Contact supplier

Check pulsating voltage (0-60

VAC) to oven

Contact supplier

Check oven resistance ± 13 !

Contact supplier

Analyzer becomes slow > 20 seconds

response time

Check system flows and gas

pressures

Clean system and/or adjust to

correct values

Check resistance of cell, when

sample gas is “shut off” it should

be lower than 1000 !

Replace Zirconia cell

No response from analyzer

Response to mV signal on cell

input terminals

Electronic problem. Check

interface board or computer

No mV signal from cell

Replace Zirconia cell

Leak in mixing system

Check for leaks

Response to mV signal on cell

input terminals

Clean systems and/or adjust to

correct values

No mA output signal

Check or the test value is set to

“NO”

Set test value to “NO”

Simulate mA signal wiring.

Check test value on 0%, 25%,

50%, 75% and 100%

Contact supplier