COSA Xentaur COSA 9610 User Manual

Page 20

INSTALLATION, OPERATION AND MAINTENANCE MANUAL – COSA 9610™

Page 20 of 44

!

Caution

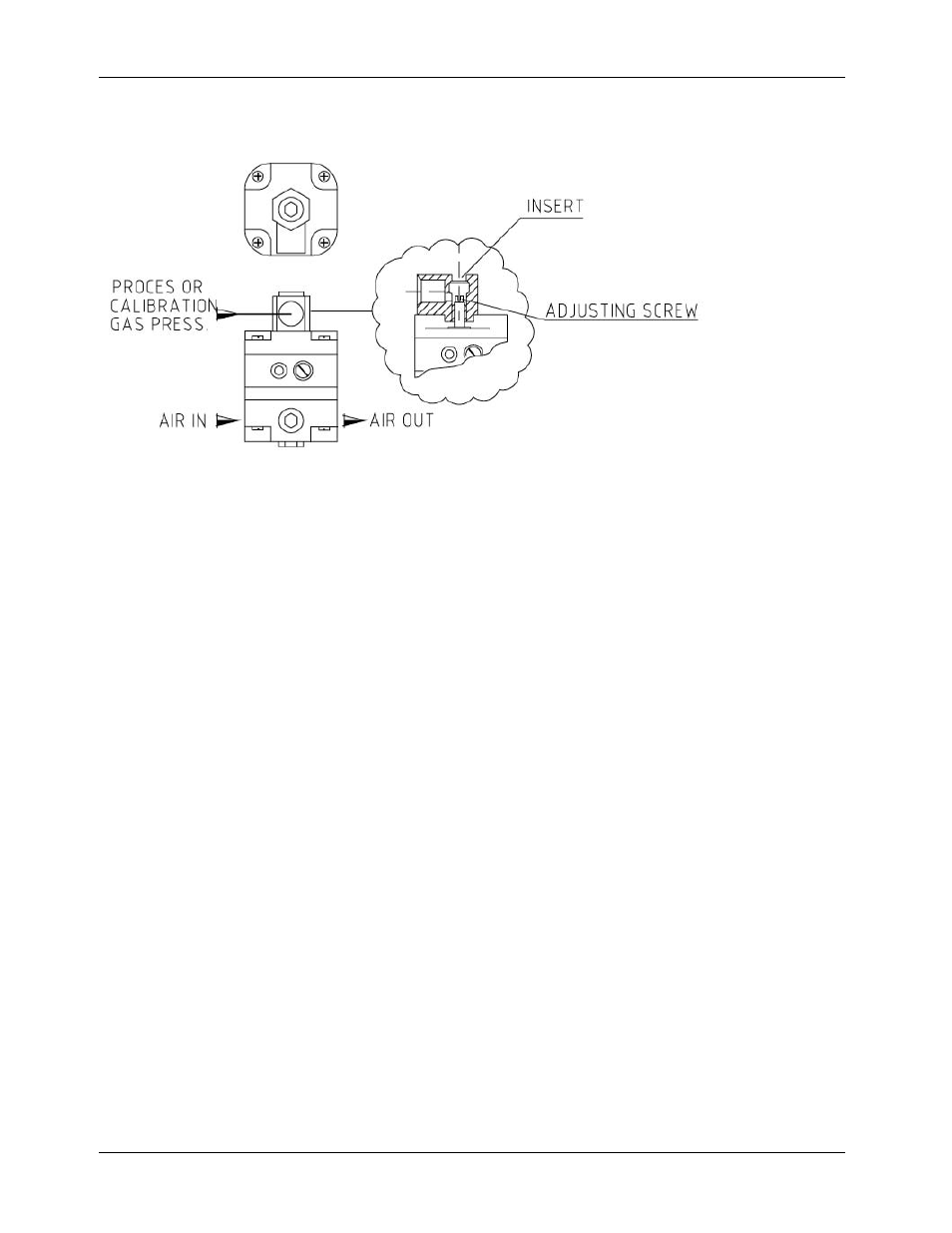

The adjusting screw is located in the gas compartment of the relay. When the insert is

released, gas will escape. Be prepared before the relay is going to be adjusted, e.g. have

the right equipment readily available, so the gas compartment has to be open for only a

minimum of time.

After this adjustment the insert must be fitted again and the offset can be checked. The

offset adjustment can be checked by reading the air and gas pressure indicators. This

operation must be repeated until the desired residual oxygen concentration is reached.

After this the insert is fitted with sealing tape, assembled and then checked for leakage by

means of either a gas leak detector or soap.

It is advisable; to carry out a check on the booster relay adjustment with high Wobbe-

Index calibration gas, directly after setting up the booster set point. Using the on-screen

menu, select 2 Points manual (Dual Range manual for dual range analyzer) validation.

Proceed to the “Wait for cal gas 2 to stable” step (“Wait for cal gas 3 to stable” for dual

range analyzer). When the signals become stable, the display will show the Residual O2

mV-value suitable to this calibration gas. The setting of the booster relay is right when the

mV-value stays below 67 mV. If not, a positive offset should be set with help of the

booster relay, so that relative more air will be added and the mV value will fall.

The required Residual O2 mV-signal should be around 65mV for the highest expected

Wobbe value.