Section 5 - start up – Van Air Systems HLSXA-55 User Manual

Page 8

PAGE 8

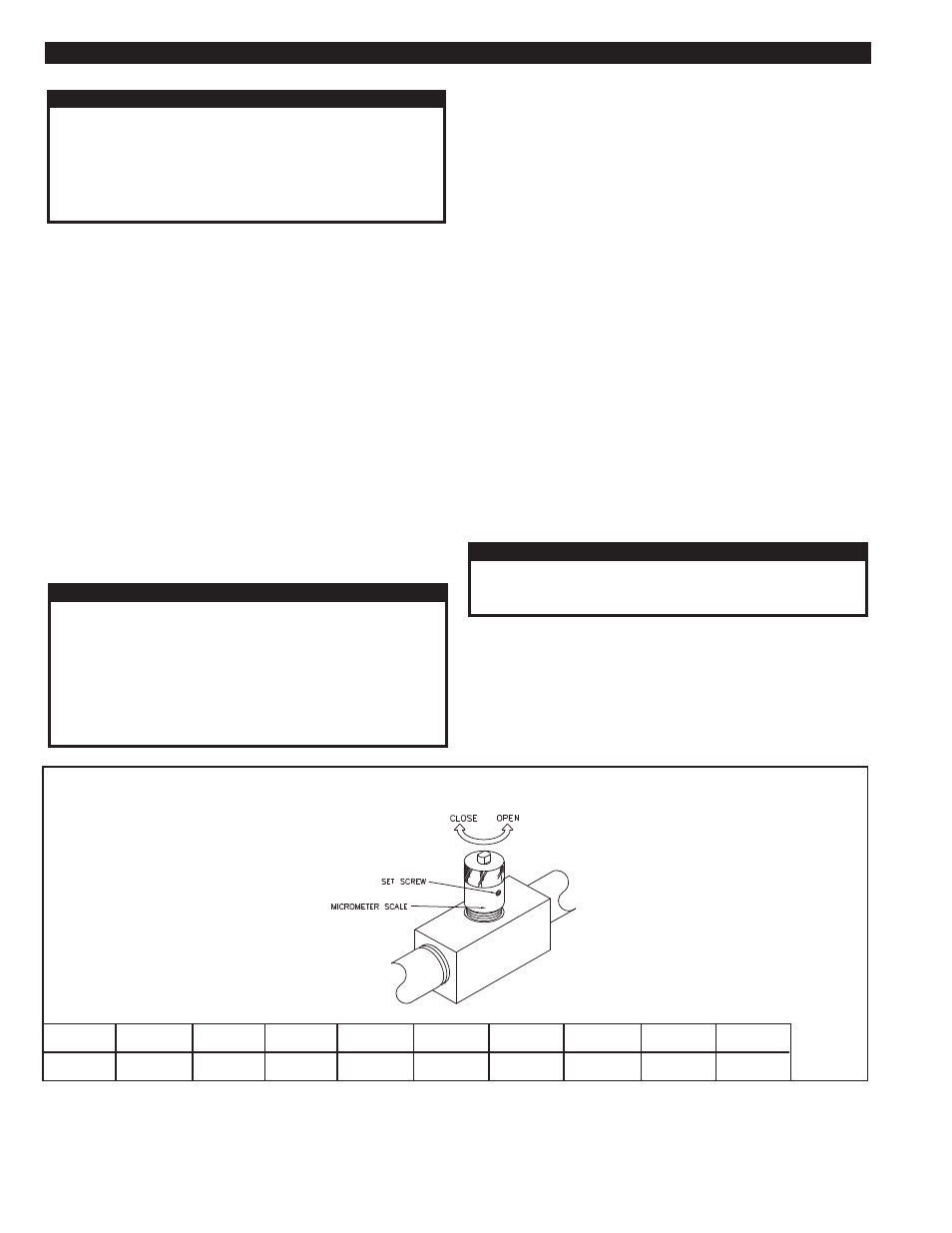

5.2 ADJUSTING THE PURGE FLOW

IMPORTANT

NEVER OPERATE THE DRYER WITH THE PURGE METERING VALVE

CLOSED. IF THE VALVE IS CLOSED, THE REGENERATING TOWER

WILL NOT REPRESSURIZE.

DO NOT ADJUST THE PURGE METERING VALVE ABOVE OR

BELOW THE RECOMMENDED SETTING FOR THE OPERATING

CONDITIONS OF THIS INSTALLATION. IMPROPER SETTING MAY

CAUSE POOR DRYER PERFORMANCE AND/OR EXCESSIVE USE

OF PROCESS AIR.

The purge flow can be adjusted to suit the operating conditions. The

micrometer type needle valve is used to set the purge flow as required.

Before placing the dryer on stream, check the purge metering valve setting.

It should be set per

FIGURE 5A. The valve is equipped with a set screw

which must be loosened before the valve is adjusted. Adjust the needle

valve to the desired setting. Tighten the set screw to prevent tampering.

START UP

SECTION 5

FIGURE 5A: PURGE METERING VALVE SETTING

5.3 CONDITIONING THE DESICCANT BED

To condition the desiccant bed, the dryer is operated without any outlet

flow, while the towers regenerate with purge air.

Turn on the Power to the dryer.

Observe the dryer for several cycles to make sure that it is operating

properly.

At initial start up or after extended shutdowns (over one month), the

dryer may take 24 to 48 hours of continuous operation for the bed to be

conditioned. Moisture that has accumulated on the desiccant bed should

be removed before the dryer is placed on stream.

Once the moisture indicator on the dryer turns blue, the desiccant bed is

conditioned and ready to be placed on-stream.

5.1 START UP

WARNING

BEFORE STARTING THIS DRYER, FOLLOW THE INSTALLATION

INSTRUCTIONS AND PROCEDURES COMPLETELY. SERIOUS

PERSONAL INJURY CAN RESULT IF INSTRUCTIONS ARE NOT

CAREFULLY AND COMPLETELY FOLLOWED.

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON THIS

DRYER SYSTEM WHILE IT IS PRESSURIZED.

Close the inlet and outlet isolation valves. Open the bypass valve (if

equipped).

Pressurize the system. Once the system is pressurized, slowly open

the inlet isolation valve.

DO NOT open the outlet isolation valve.

Turn

ON the power supply to the dryer. One tower will pressurize. The

other tower will remain depressurized. The purge valve will open and

purge air should be exhausting from the dryer.

Dryer will begin a 10 minute cycle. The dryer will operate for 5 minutes

on each tower.

The dryer is equipped with a purge metering valve. The setting should

be checked before placing the dryer on stream. See

SECTION 5.2.

The desiccant bed should be conditioned per

SECTION 5.3 before

placing the dryer on-stream.

Place the dryer on-stream by opening the outlet isolation valve and

closing the by pass valve (if equipped).

5.4 SETTING THE CONTROL PRESSURE REGULATOR

The control pressure regulator is located near the control box and it is

used to protect the pneumatic actuators on the purge and inlet transfer

valves. This regulator should be set at 100 PSIG.

IMPORTANT

DO NOT OPERATE THIS DRYER WITH THE CONTROL PRESSURE

REGULATOR ABOVE 100 PSIG TO PREVENT DAMAGE TO THE

PNEUMATIC CONTROLS.

5.5 DRYER TIMING ADJUSTMENT

For operation at pressures other than 100 PSIG, the repressurization

time may need to be lengthened to allow for complete repressurization.

Consult factory for timing changes.

PURGE

10 SCFM

80 PSIG

2.6 turns

MODEL

HLSXA55

100 PSIG

2.4 turns

125 PSIG

2.3 turns

150 PSIG

2.2 turns

175 PSIG

2.0 turns

200 PSIG

1.8 turns

225 PSIG

1.6 turns

250 PSIG

1.4 turns