Van Air Systems D8 User Manual

Page 6

PAGE 6

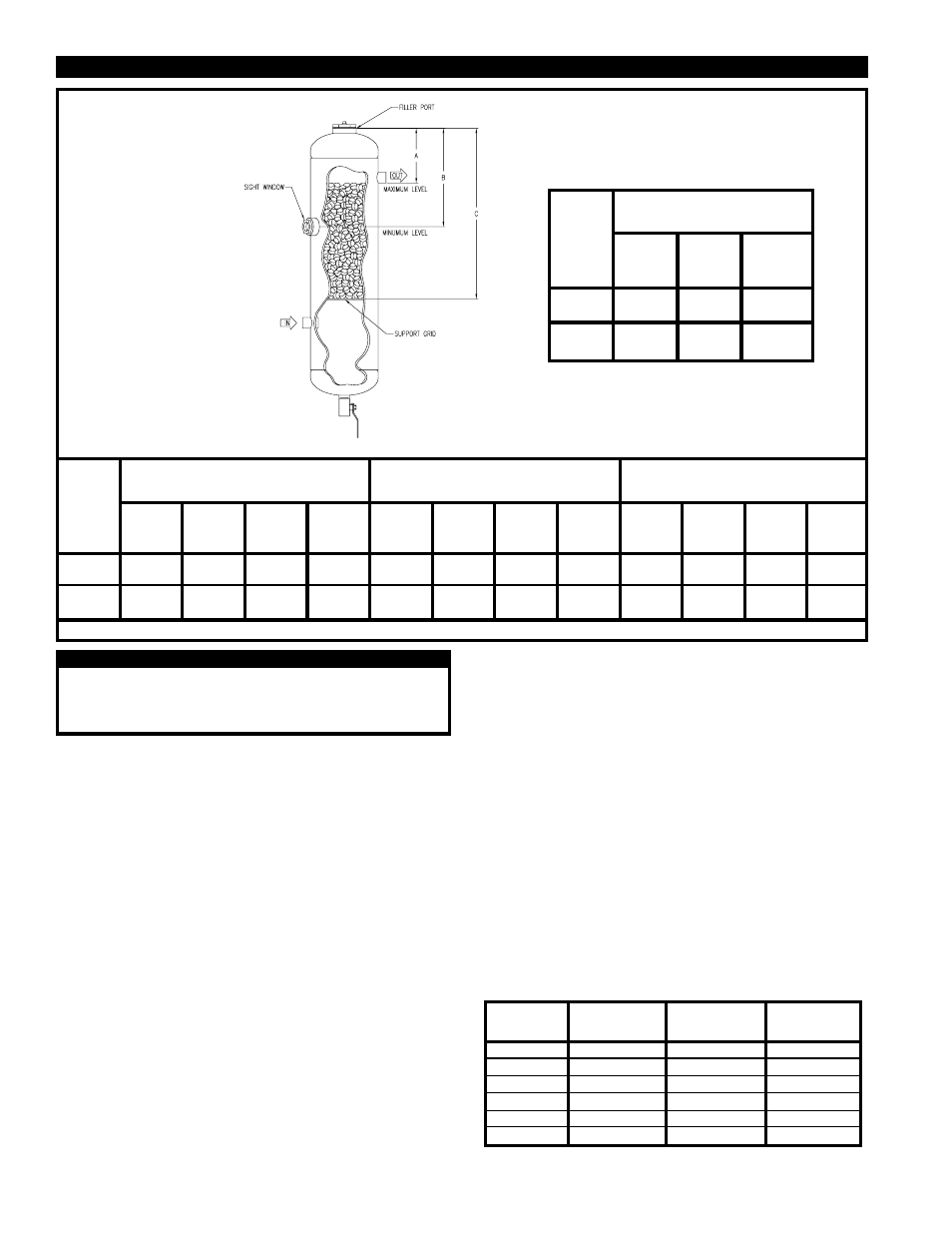

A

MAX.

Level

5-1/4"

(13.33)

6-15/16"

(17.62)

B

MIN.

Level

7-11/16"

(19.53)

12-1/2"

(31.75)

C

Total

Depth

17-11/16"

(44.93)

21-11/16"

(55.09)

BED DIMENSIONS

INCHES (centimeters)

MODEL

D4

D8

SECTION 4

MAINTENANCE

Lbs./In

of bed**

0.55

0.25

2.32

1.05

MIN.

Level

5.53

2.51

21.61

9.80

MAX

Level

6.86

3.11

34.44

15.62

MIN to

MAX

Level

1.33

0.60

12.83

5.82

Lbs./In

of bed**

0.405

0.18

1.70

0.77

MIN.

Level

4.05

1.84

15.84

7.19

MAX

Level

5.02

2.28

25.24

11.45

MIN to

MAX

Level

0.97

0.44

9.40

4.26

Lbs./In

of bed**

0.48

0.22

2.01

0.91

MAX

Level

5.96

2.70

29.84

13.54

MIN to

MAX

Level

1.16

0.53

11.12

5.04

MIN.

Level

4.8

2.18

18.72

8.49

DRY-O-LITE QUANTITY*

POUNDS (kilograms)

MODEL

D4

D8

SP QUANTITY*

POUNDS (kilograms)

10 BF QUANTITY*

POUNDS (kilograms)

* Amounts are pounds (kilograms) required to fill dryer to levels indicated.

** Amounts in italics are kilograms per centimeter of bed depth.

CAUTION

Make sure that the desiccant does not cover the screen on the

outlet pipe.

Do NOT overfill the vessel.

Start up the dryer following the procedures in Section 3.1.

4.4-A BED LEVEL GUIDE

To determine the supply of desiccant in the dryer, insert a

measuring stick through the fill port until it reaches the top of the

desiccant bed; dimensions in FIGURE 5 are calculated from the fill

port to levels indicated on the drawing. (NOTE: Dimensions are

approximate and are intended as a general guide only.)

4.4-B DESICCANT USAGE GUIDE

The chemical and physical characteristics of Van Air desiccant

contribute to its effectiveness and economy.

The DESICCANT CONSUMPTION RATE should be used as a guide

to estimate the usage of desiccant your installation will require. The

formula is based on an annual usage rate of one shift per day, 5 days

per week and 50 weeks per year or 2,000 operating hours per year.

The figure is an average and may vary depending upon your actual

conditions (i.e. 24 hour operation, higher inlet temperature, excessive

liquid water content and/or contaminants.)

DESICCANT CONSUMPTION

(Based upon 1 shift for a one year period @ 100 psig inlet pressure and

75

o

F inlet temperature, 100% RH.)

To use the chart, first determine the SCFM that is being processed

through the dryer. Locate the nearest flow rate listed on the chart

and interpolate as necessary.

The consumption rate is proportional to the moisture loading. Each

20

o

F change in inlet temperature changes the moisture loading by a

factor of nearly 2:1.

The quantity shown in the consumption rate chart is NOT the

quantity that must be added to the dryer at one time. The bed level

should be maintained at least to the minimum level at all times to

ensure optimum drying capabilities. The consumption rate is an

approximation of how much desiccant will be added over a period of

one year.

The desiccant bed should be filled approximately 2 to 3 times a year.

FLOW

SCFM

10

20

40

50

75

100

DRY-O-LITE

LBS/YEAR

13.2

26.4

52.8

66.0

99.0

132.0

SP

LBS/YEAR

66.5

133

266

332.5

498.8

665.0

10 BF

LBS/YEAR

57.6

115.2

230.4

288.0

432.0

576.0

FIGURE 5 BED LEVEL DETAIL