Van Air Systems D8 User Manual

Page 4

PAGE 4

SECTION 2

INSTALLATION

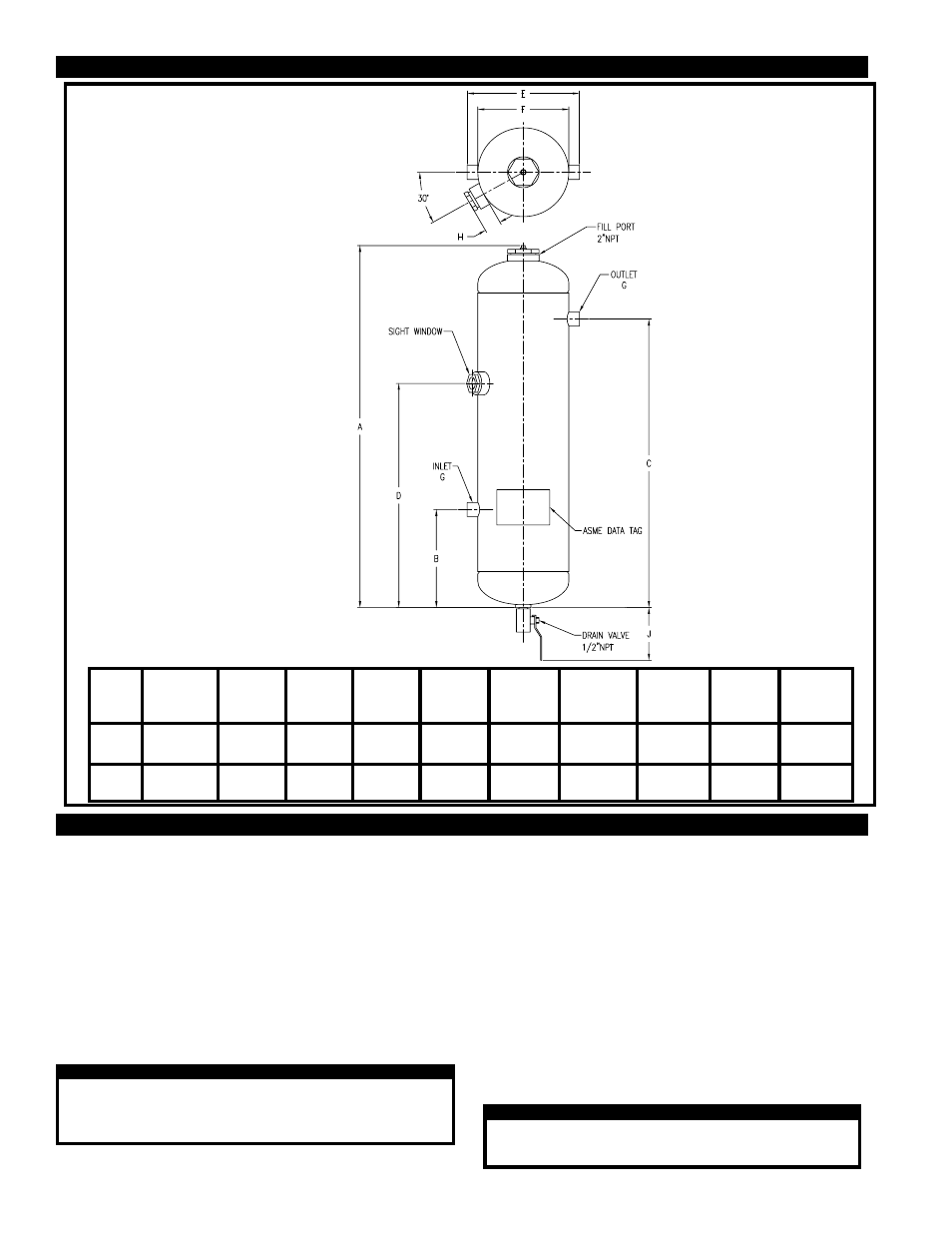

FIGURE 4 DRYER DIMENSIONAL DETAILS

MODEL

NO.

D 4

D 8

APPROX

WEIGHT

w/o

Desiccant

30 LBS

60 LBS

A

27-3/4"

704.9mm

35-1/16"

890.6mm

C

22-7/16"

569.9mm

28"

711.2mm

D

19-5/16"

490.5mm

21-3/4"

552.5mm

E

6-1/2"

165.1mm

10-5/8"

269.9mm

F

4-1/2"

114.3mm

8-5/8"

219.1mm

G

3/4" NPT

3/4" NPT

B

6-15/16"

176.2mm

9-1/2"

241.3mm

H

1-3/8"

34.9mm

1-9/16"

39.7mm

J

5-1/8"

130.2mm

5-1/8"

130.2mm

SECTION 3

OPERATION

3.1 START UP PROCEDURES

Close the inlet isolation valve and open the bypass valve.

Open the outlet isolation valve SLOWLY and allow some air to bleed

through the drain valve; then close the drain valve. When the dryer

reaches normal operating pressure, SLOWLY turn the inlet valve to full

open position; then close the bypass valve.

If the vessel was installed without the bypass or isolation valves,

SLOWLY pressurize the air system. Allow some air to bleed through the

drain valve. Once the vessel starts to pressurize, the drain valve can be

closed.

Close the bypass valve, the dryer is now on stream.

CAUTION

Make sure that the dryer is not subjected to sudden flow

surges. Always open the valves slowly to permit gradual

equalization of pressure between the dryer and the air supply

lines.

3.2 OPERATING THE DRYER

The simple design of the single tower dryer allows for easy

operation.

The dryer requires two procedures to ensure peak performance.

3.2-A DAILY DRAINING

The accumulated solution in the bottom of the dryer should be

drained at least once for every 8 hours of operation. Depending

upon actual operating conditions, the dryer may require draining

on a more frequent basis.

If an automatic ball valve type drain valve was installed on the

dryer, set the time cycle for every 4 to 8 hours. The manual drain

valve must be opened at least once every 4 to 8 hours to drain the

dryer.

CAUTION

If the dryer is not drained regularly, it may become

flooded. Accumulated liquid may enter the air system

and cause damage to downstream equipment.