Van Air Systems D8 User Manual

Page 2

PAGE 2

SECTION 1

INTRODUCTION

1.0 PURPOSE OF OPERATION

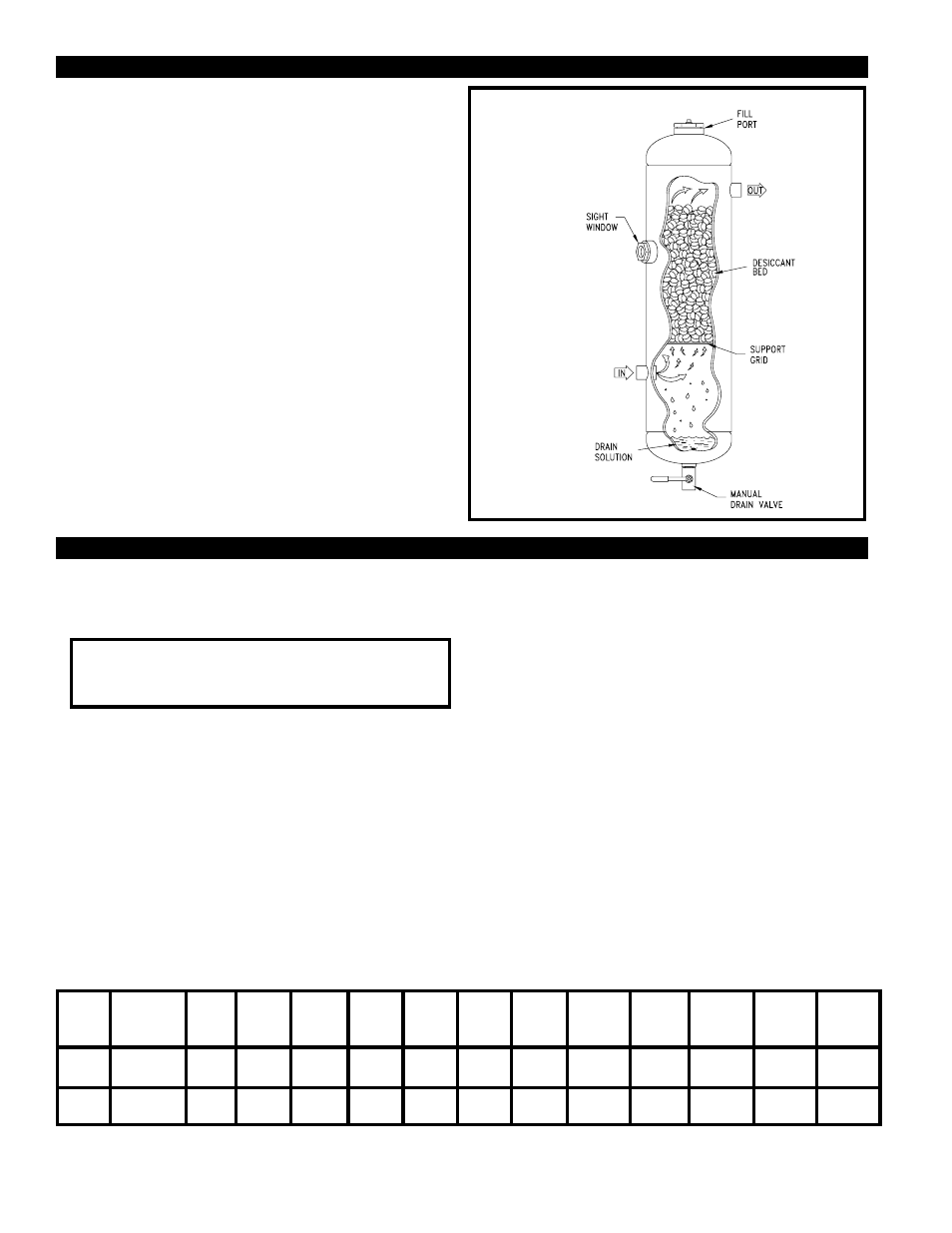

The purpose of installing a Van Air single tower dryer in a

compressed air system is to remove the water vapor (humidity) which

has been drawn into the system at the compressor intake. The Van

Air process dries the air as it flows through the vessel, which is filled

with a special drying agent. The dryer operates automatically. There

are no moving parts and no external source of power is required. If

an automatic drain is installed, a power source is required only to

operate the valve.

The wet air enters the centrally located inlet which channels the flow

into the lower portion of the dryer. Liquid water and solid particles are

separated by gravity and fall to the bottom of the vessel.

The process air moves upward through the bed of desiccant tablets

which attract and absorb the moisture from the air before it flows

through the dryer outlet. The tablets dissolve gradually as they

absorb the moisture.

The tablets create a structured bed that does not crush under its own

weight. In the bed of an operating dryer, the lower tablets are

consumed first.

The tablets in the top portion serve as a reserve supply. When the

reserve supply is depleted, the dryer must be refilled to maintain

performance.

The solution, which consists of dissolved desiccant and water, falls

into the claim area at the bottom of the vessel. The dryer must be

drained at least once a shift to remove the accumulated solution.

FIGURE 1 DRYER DETAILS

SECTION 2

INSTALLATION

2.1 LOCATION

The ability of a dryer to provide dry compressed air depends on the

correct location of the unit. Inlet air temperature and pressure are the

keys to selecting the proper location.

IMPORTANT

ALWAYS PROCESS AIR THROUGH THE DRYER AT THE

LOWEST POSSIBLE TEMPERATURE AND THE HIGHEST

PRACTICAL PRESSURE.

2.1-A INLET AIR TEMPERATURE

The dew point of the outlet air is directly related to the inlet air

temperature and the type of desiccant being used. The lower the inlet

temperature, the lower the dew point of the outlet air. Determine the

lowest ambient temperature where the compressed air is used or

where the lines are located. If you are using DRY-O-LITE or 10BF

desiccants, do not exceed 100

o

F inlet air temperature. If you are

using SP desiccant, do not exceed 80

o

F inlet air temperature.

2.1-B AFTERCOOLING

Air discharged by the compressor is extremely hot (from 150

o

F to

350

o

F). An aftercooler, finned tubing or extended run of piping will

usually be necessary to reduce the inlet air temperature to the dryer.

2.1-C OUTDOOR AIR USAGE

If some or all of the air supplied by the Van Air single tower dryer will

be used outdoors, install the dryer outdoors in the coolest possible

FIGURE 2 MAXIMUM CAPACITIES -SCFM (Nm

3

/hr)

MODEL

NO.

D 4

D 8

MAXIMUM

WORKING

PRESSURE

250 PSIG

250 PSIG

200 PSIG

13.8 Bar

18.7

30.1

94

151

100 PSIG

6.9 Bar

10

16

50

80

125 PSIG

8.6 Bar

12.2

19.6

61

98

150 PSIG

10.3 Bar

14.4

23.2

72

116

40 PSIG

2.8 Bar

4.8

7.7

24

38.6

60 PSIG

4.1 Bar

6.5

10.5

33

53

80 PSIG

5.5 Bar

8.3

13.3

41

66

90 PSIG

6.2 Bar

9.1

14.6

46

74

20 PSIG

1.4 Bar

3

4.8

15

24.1

10 PSIG

0.7 Bar

2.2

3.5

11

17.7

5 PSIG

0.3 Bar

1.7

2.7

9

14.5

area. Make sure that the dryer is not exposed to ambient temperatures

below the minimum design temperature stamped on the vessel data

tag. When the dryer will be exposed to the direct rays of the sun,

install a sun shield to protect it (i.e. a roof).

2.1-D INDOOR AIR USAGE

If all of the air from the dryer will be used indoors where temperatures

remain within a fixed range, locate the dryer in the coolest indoor

area. When air equipment or piping is located in an air conditioned

area, install the dryer in the coolest area--usually the air conditioned

area.

2.1-E AIR RECEIVER

The Van Air single tower dryer should be located where it will be

provided with the coolest inlet temperature. If the receiver is located

in an area where the ambient temperature is lower than the outlet air

from the aftercooler, locate the dryer downstream of the receiver to

allow additional cooling of the air before it enters the dryer. (Exception:

In systems where usage creates sudden demands on the air supply,

locate dryer before the receiver to minimize air surges through the

dryer.) If the ambient temperature around the receiver is higher than

the outlet air temperature from the aftercooler, locate the dryer

between the aftercooler and the receiver.

2.1-F SPECIAL EQUIPMENT INSTALLATION

If the Van Air Dryer is being installed on a branch line to protect a

specific piece of air-operated equipment, locate the dryer on the high

pressure side of any pressure regulators.

250 PSIG

17.2 Bar

23.1

37.1

115

185