0 troubleshooting, 4 maintenance schedule, 1 troubleshooting toolbars – Seed Hawk TOOLBAR 2014 User Manual

Page 28

SEED HAWK

®

2014 TOOLBAR OPERATOR’S MANUAL

SEED HAWK

®

2014 TOOLBAR OPERATOR’S MANUAL

48

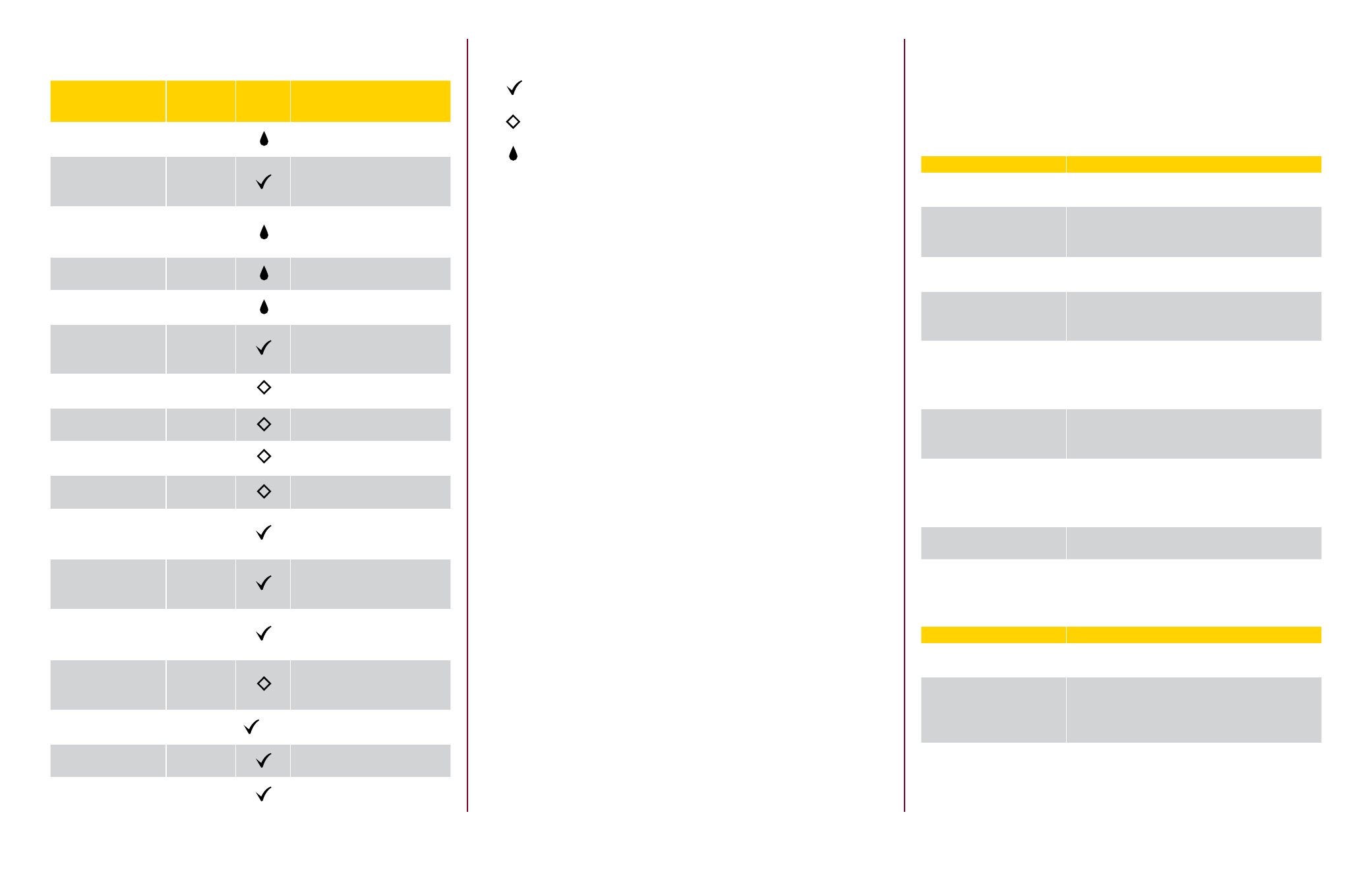

Item

Frequency

(hours)

Service

Notes

Castor Wheel Plate

grease fittings

12

Daily

2 fittings: 1-top, 1-bottom

Castor Wheel

Plate gap

100

1/8” (3mm) max

tighten castor bolt if max

exceeded

Wheel Hubs

main frame

100

100 hrs or annually re-pack

bearings or 2 pumps grease

Wheel Hubs wing

100

100 hrs or annually

Wheel Hubs

packer wheel

100

100 hrs or annually

Seed/Fertilizer

Knives & related

components

10/100

10 hrs or inspect daily, and,

100 hrs or before seeding

Liquid Fertilizer (opt)

main filter screens

100

100 hrs or before seeding, or

between chemical changes

Liquid Fertilizer (opt)

basket filter(s)

50

50 hrs or before seeding, or

between chemical changes

Liquid Fertilizer (opt)

system flush

100

100 hrs or before seeding, or

between chemical changes

Liquid Fertilizer (opt)

nozzle bodies

100

100 hrs or before seeding, or

between chemical changes

Wings down

(if configured)

100

At end of seeding season, or

when stored for long periods

of time

Ball Lock Valves

open

100

At end of seeding season, or

when stored for long periods

of time

Dump Line

open - drain in pail

100

At end of seeding season, or

when stored for long periods

of time

Dump Line

open - drain in pail

100

At end of seeding season, or

when stored for long periods

of time

Hydraulic Cylinders

cylinder seals

10 /

A/R

10 hrs or daily; inspect &

replace as required (A/R)

Tires

air pressure

10

10 hrs or daily; inflate to

proper pressure

Opener Pivot Points

100

Annually re-torque

6.4 Maintenance Schedule

A/R

Replace as

Required

A/R

Check

Clean

Lube

49

7.1 Troubleshooting Toolbars

7.0 Troubleshooting

Probable Cause

Solution

Incomplete engagement of

hydraulic quick couplers.

Inspect quick couplers to ensure complete en-

gagement.

Lock valves for shanks are

set in closed position.

Ensure that both lock valves, one at the manifold

and one at the tractor quick coupler, are set to

the open position.

No electrical power to

shank solenoid valve.

Check for broken wire in harness to solenoid

coil.

No electrical power to

shank pressure adjustment

motor.

Check for broken wire to shank pressure adjust-

ment motor.

Tractor hydraulic selector

valve not holding pressure.

Disconnect coupler at Circuit #1. If pressure is

now adjustable, repair the tractor selector valve

(make sure the lever is in working position not

float).

Solenoid coil

malfunctioning.

Activate solenoid valve manual override. If the

shank pressure responds properly, replace the

coil also check for power going to coil.

Shank solenoid valve

cartridge contaminated.

Remove solenoid valve cartridge per repair in-

structions in the maintenance section of this Op-

erator’s Manual, inspect to make sure all o-rings

are not damaged, then clean and replace.

Shank pressure gauge

malfunctioning.

Remove and replace pressure gauge if not re-

sponding to increase and decrease of pressure.

Cannot Adjust Shank Pressure

Shanks do not maintain trip/packing pressure on hilly

terrain

Probable Cause

Solution

The “IN” pressure gauge

indicates less than 1200 psi.

Inspect quick couplers to ensure complete en-

gagement.

Excessive field operating

speed.

Reduce field operating speed. Note: Trip/packing

pressure may be momentarily increased by acti-

vating hydraulic Circuit #1 while passing through

a shallow dip in the terrain.

Intermittent electrical

power supply to shank

solenoid coil.

Ensure all electrical connections are fully engaged

and no open electrical circuits to coil.