9 crop residue considerations, 3 twin wing – Seed Hawk TOOLBAR 2014 User Manual

Page 22

SEED HAWK

®

2014 TOOLBAR OPERATOR’S MANUAL

SEED HAWK

®

2014 TOOLBAR OPERATOR’S MANUAL

36

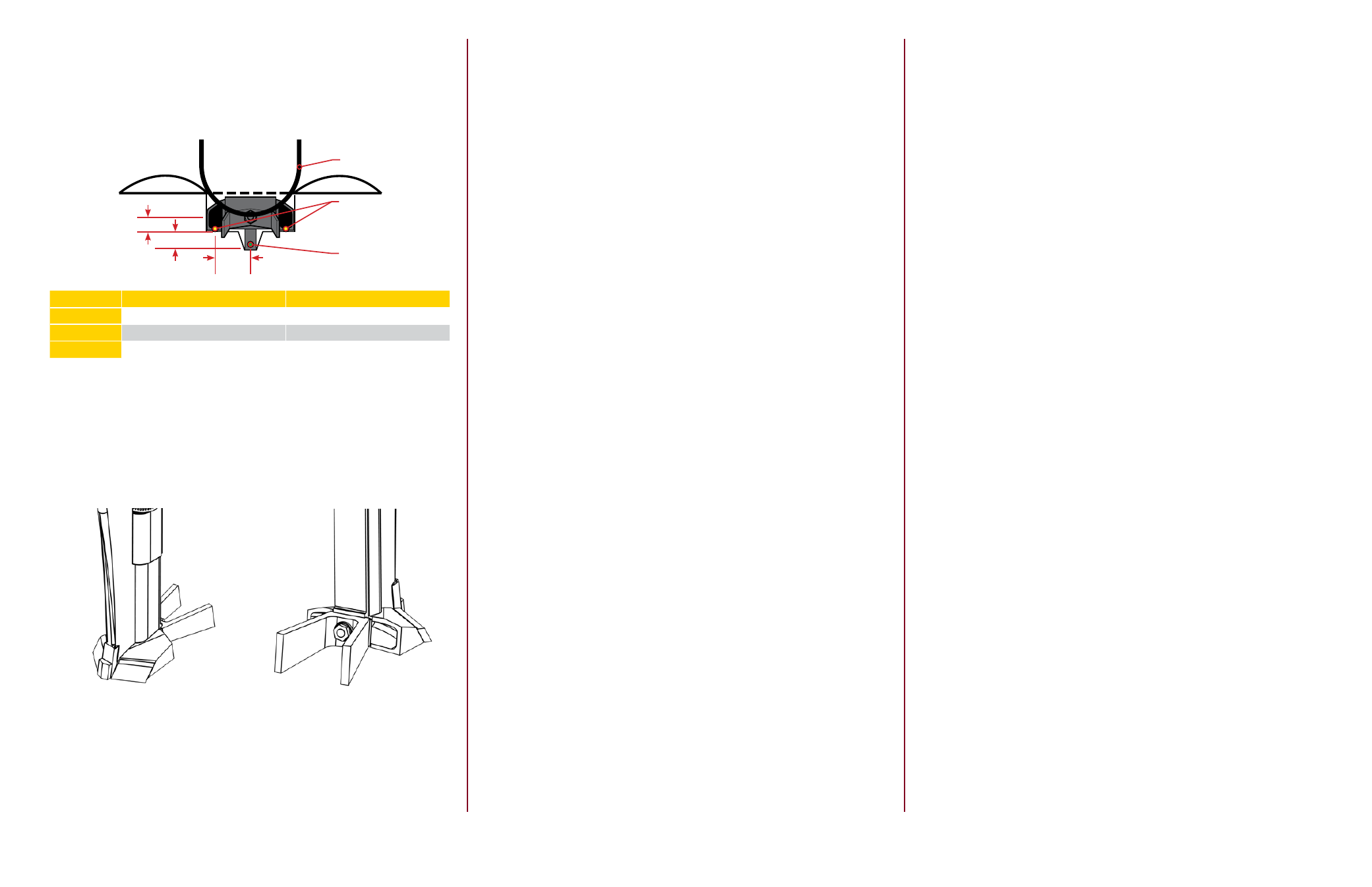

4.8.3 Twin Wing

The Twin Wing Seed™ opener creates a dual row, resulting in higher seedbed

utilization. The furrow, however, maintains the ideal seed and fertilizer placement

as the original single sideband opener.

Most Twin Wing™ openers are on 12 in. spacing. The grower can achieve 9 in.

spacing due to the 3 in. seed separation. With Single Side Band configuration,

10 in. spacing is the narrowest spacing that Seed Hawk offers.

What Twin Wing achieves is two rows of seed ¾ in. above and 1-½ in. to both

sides of the fertilizer band. The 1-½ in. separation to the side of the fertilizer

band is identical separation as the Single Side Band seed opener.

Contact local dealer for instructions on how to convert Single Side Band open-

er to accommodate the Twin Wing™ seed knife.

Seed

Packer Tire

Y

Z

X

Item

Dimension

Description

X

¾ in. (19mm)

Seed Depth

Y

¾ in. (19mm)

Seed to Fertilizer Depth

Z

1-½ in. (38mm)

Seed to Fertilizer Separation

Fertilizer

37

4.9 Crop Residue Considerations

Seeding into fields with heavy residue is challenging, but residue cover is essen-

tial to the success of a zero-till cropping system. Ideally, the straw height from

the previous year will be less than or equal to the width of the Seed Hawk

®

Drill row spacing.

For optimum results, the combine harvester should chop the straw and spread

the straw and chaff evenly across the entire swath width. The fertilizer and seed

knives will catch and drag small amounts of crop residue while seeding. Some

small clumps of straw may be deposited along the seed row making the finished

seed bed appear rough.

IMPORTANT! Avoid harrowing after seeding with the Seed Hawk Drill.

Harrowing after seeding can drastically alter seed depth. Although tempting to

harrow to smooth out straw clumps, these clumps will smooth out over time

and exposure to the weather.

Increased humidity will reduce the ease with which the straw will flow around

the knives. Increased humidity near the soil surface is more common during

the first few years of zero-till. This is due to lower soil porosity and infiltration

rates. With time, the soil porosity and infiltration rates will rise, and the humidi-

ty will decrease.