Tapped chamber vents, Diaphragm replacement, Reassembly after service – SANDPIPER W15 User Manual

Page 4: Warranty, Warning

7/04 520-150-000

Models W09 & W15 Page 4

TAPPED CHAMBER VENTS

The chamber vent at the top of each outer chamber (see Figure 5) is used to

purge any entrapped air that might accumulate in the chamber. Entrapped air

could cause unbalanced cycling or loss of prime. The gate valve with 1/2" NPT

(12.7mm) threads accomodates a hose or pipe, to vent accumulated air and

fluid back to the liquid source. Ends of the hose or pipe must be submerged in

the liquid being pumped. Tying the pump sides together into a common hose

only moves the air from side to side.

When air is purged, pumped product will discharge from the hose. When

this occurs, close the gate valve and continue normal operation. The valves

may be left partially open, but pump performance will decrease. The tapped

chamber vents can also be used to flush the chambers between uses.

DIAPHRAGM REPLACEMENT

Diaphragms are in-line accessible for service, without disturbing the suction

and discharge flanges. To access the diaphragm, remove the eight (8) locking

knobs around the diaphragm chamber. Remove the locking knobs at the

manifold elbow connections. The housing assembly will pull off. Diaphragms

can now be inspected or replaced. Clear all foreign matter from behind the

diaphragm before reassembling.

REASSEMBLY AFTER SERVICE

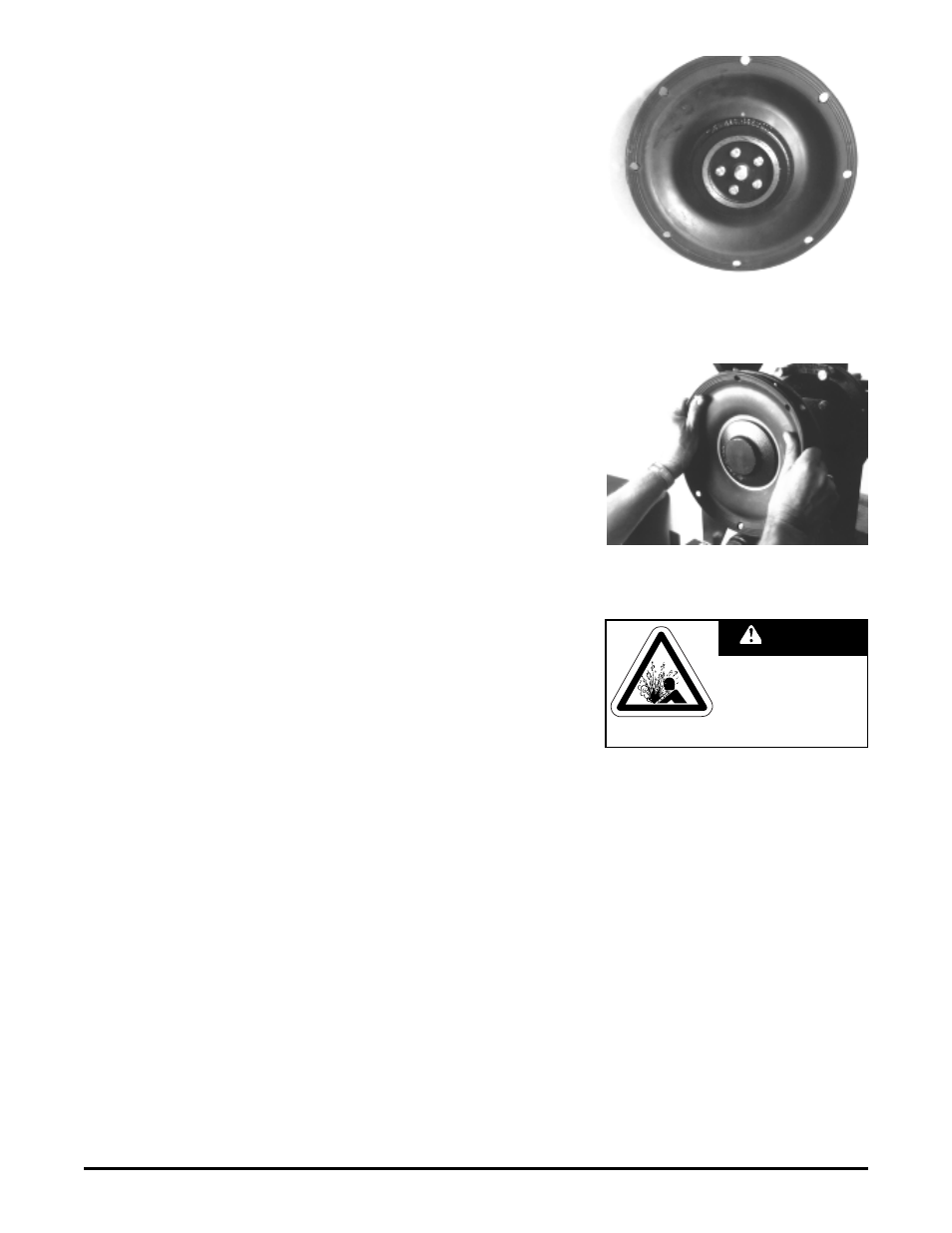

To reassemble the pump, begin with the diaphragm assembly. Stack the

wear pad onto the stud of the outer plate. Next, put the diaphragm on to the

stud, with the natural bulge toward the outer plate. Place the inner plate onto

the stud.

Align the five (5) hexhead capscrews and washers through the inner plate,

diaphragm and wear pad, into the outer plate (See Figure 6). Tighten the

capscrews alternately, side to side and corner to corner, use 242 Loctite and

torque to 190 in/lbs. Place the bumper onto the diaphragm rod.

Once the diaphragm assembly is made, thread the stud (from the outer

plate side) into the diaphragm rod. Use Neverseize

®

or equivalent anti-galling

thread lubricant on threads. Turn the assembly onto the rod until it bottoms out,

and the eight (8) holes around the outside of the diaphragm line up with those

on the outer chamber rim (See Figure 7). Back-off tightening as required for

alignment. Reassemble the other side of the pump in the same way. Tighten all

locking knobs to secure the outer chamber to the inner chamber. Tighten all

knobs alternately, side to side and corner to corner.

WARRANTY

This pump is warranted for a period of five years against defective material

and workmanship. Failure to comply with the recommendations stated in this

manual voids all factory warranty.

©2004 Warren Rupp, Inc. All rights reserved.

®Warren Rupp, SANDPIPER and Tranquilizer are registered tradenames of Warren Rupp, Inc.

®Neverseize is a registered tradename of Loctite

Printed in U.S.A.

Figure 6: Align hexhead capscrews and tighten

Figure 7: Align diaphragm holes with chamber

holes

This pump is pressurized

internally with air pressure

during operation. Always

make certain that all bolting

is in good condition and that

all of the correct bolting is

reinstalled during assembly.

WARNING