Installation, Technical specifications – stt-10 heads & controls, General description – Lincoln Electric IM586 STT-10 Head & Controls User Manual

Page 9

A-1

INSTALLATION

STT-10

A-1

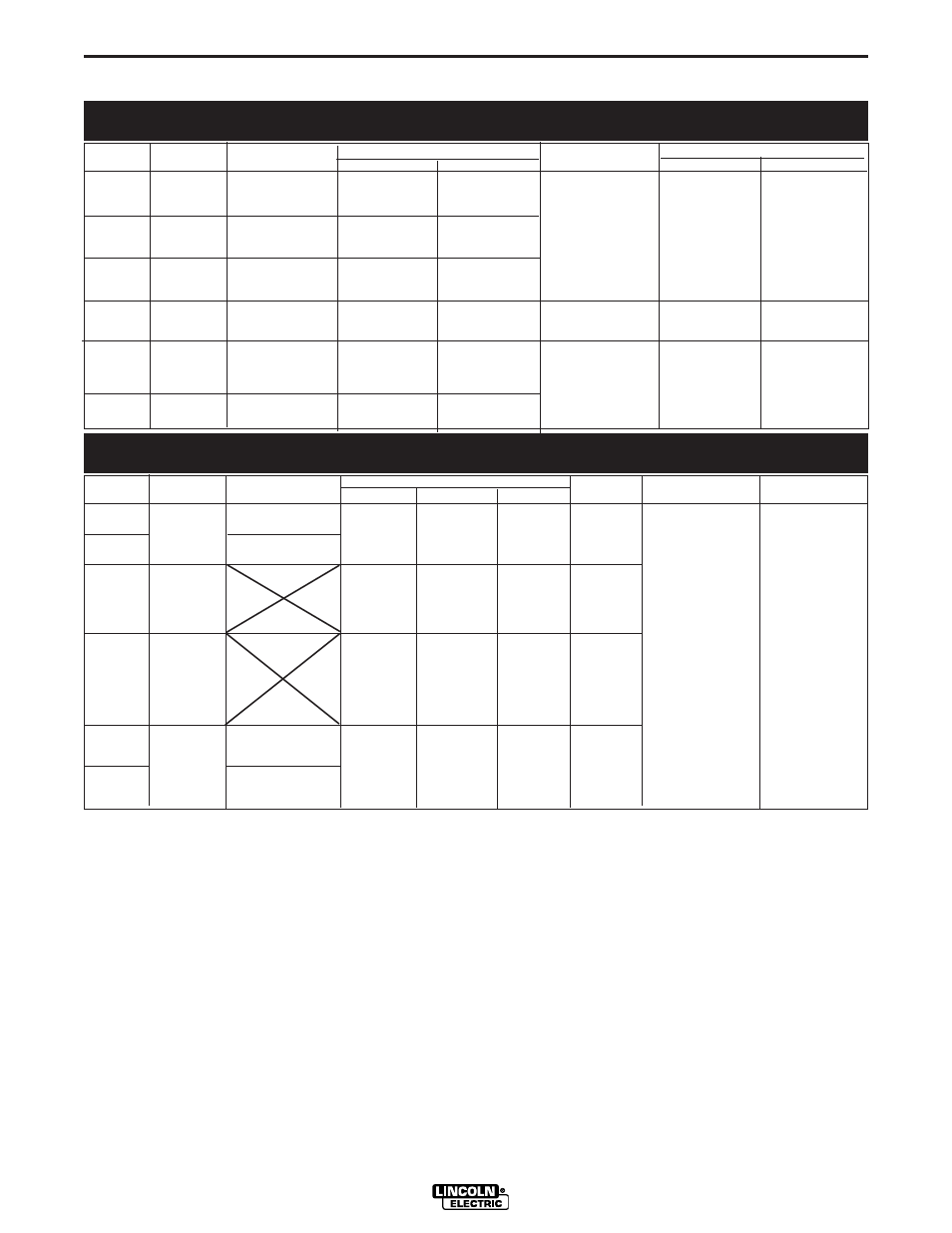

TECHNICAL SPECIFICATIONS – STT-10 Heads & Controls

WIRE DRIVE OR WIRE DRIVE SECTION OF FEEDER

SPEC.#

TYPE

LOW SPEED RATIO HIGH SPEED RATIO

• Excluding Wire Reel

Δ Included with K1568-Series STT-10 Boom Package

*Synergic 7F drives use 4-roll drives with 2 driven rolls(Drive roll kits not common with 10 Series heads)

Wire Size

Wire Size

Speed

Solid

Cored

Speed

Solid

Cored

K1563-1Δ, 10 Series

35-500 IPM

.025 - 3/32 in.

.030 - .120 in

K1563-3

Boom Mount (0.89-12.7 m/m)

(0.6 - 2.4 mm)

(0.8 - 3.0 mm)

K679-1

Synergic 7F* 50 - 770 IPM

.025 - 1/16 in.

.035 - 5/64 in.

Std Drive

Boom Mount (1.27 - 19.5 m/m)

(0.6 - 1.6 mm)

(0.9 - 2.0 mm)

K679-2

Synergic 7F*

---

---

---

80 - 1200 IPM

.025 - .045 in.

.035 - .045 in.

Hi-Speed

Boom Mount

(2.00 - 30.5 M/M)

(0.6 - 1.2 mm)

(0.9 - 1.2 mm)

K1560-1,-2 STT-10

35-500 IPM

.025 - 3/32 in.

.030 - .120 in.

Bench Model (0.89-12.7 m/m)

(0.6 - 2.4 mm)

(0.8 - 3.0 mm)

CONTROLS, HEADS AND COMPLETE UNITS

SPEC.#

TYPE

INPUT POWER

PHYSICAL SIZE•

TEMPERATURE RATING

Dimensions

Height

Width

Depth

Weight

Operating

Storage

K1565-1Δ

40-42 Vac ± 10%

Controls

STT-10

4.0 Amps 50/60 Hz 14.80 “

14.20 “

4.20 “

18.0 Lbs

K1565-2

Controls

40-42 Vac ± 10%

(375.9 mm)

( 360.7mm)

(106.7 mm) (8.2 Kg)

Controls

6.0 Amps 50/60 Hz

K1568-1Δ

10 Series

7.81 “

14.71 “

11.00“

25.0Lbs

Std Drive

Boom Mount

(198.4 mm)

(373.6 mm)

(27.94 mm) (11.3 Kg)

+40°C

+40°C

to

to

K679-1,-2 Synergic 7F*

11.5“

7.16“

8.06“

16.5 Lbs

-20°C

-40°C

Std Drive

Boom Mount

( 285.8mm)

(181.9 mm)

(204.7mm) (7.5 Kg.)

K1560-1

40-42 Vac ± 10%

Std Feeder

4.0 Amps 50/60 Hz

STT-10

20.46 “

14.43 “

30.35 “

65.0 Lbs

K1560-2

Bench Model 40-42 Vac ± 10%

(519.7 mm)

(366.5 mm)

(770.9 mm) (29.5 Kg)

Std Feeder

6.0 Amps 50/60 Hz

GENERAL DESCRIPTION

The STT-10 is a modular line of 42VAC input 4-roll wire

feeders. A single control with dual procedure presettability

of wire feed speed (in IPM or M/min), peak current, and

background current is used with the STT-II power source.

Preset Ranges can be set independently for each procedure

for peak current, background current, and wire feed speed.

The STT-10 models have controls providing keypad or

remote selectability of either of two procedures.

The units offer 4 independently selectable gun trigger

modes for each procedure; cold feed, 2 step and 4-step trig-

ger and spot weld mode.

Also, 4 selectable, presettable timers for each procedure;

preflow, postflow, burnback and spot weld time.

Arc starting can be optimized for each procedure with 5

selectable wire feed acceleration rates, and independent

control of slower run-in procedure.

A gas purge key is provided, as well as cold feed forward

and reverse keys with adjustable forward feed speed setting.

Allot these features are selected with a tactile-feel keypad,

and are set independently using one of two rotating knob

encoders, setting levels are displayed on one of two digital

LED displays.