Operation, B-25, Machine functionality by weld process – Lincoln Electric IM915 POWER FEED 10M SINGLE WIRE FEEDER User Manual

Page 47

Material

Steel

Steel

Steel

PROCESS

GMAW, CV

GMAW, POWER MODE

FCAW, CV

WELD MODE

5

40

6

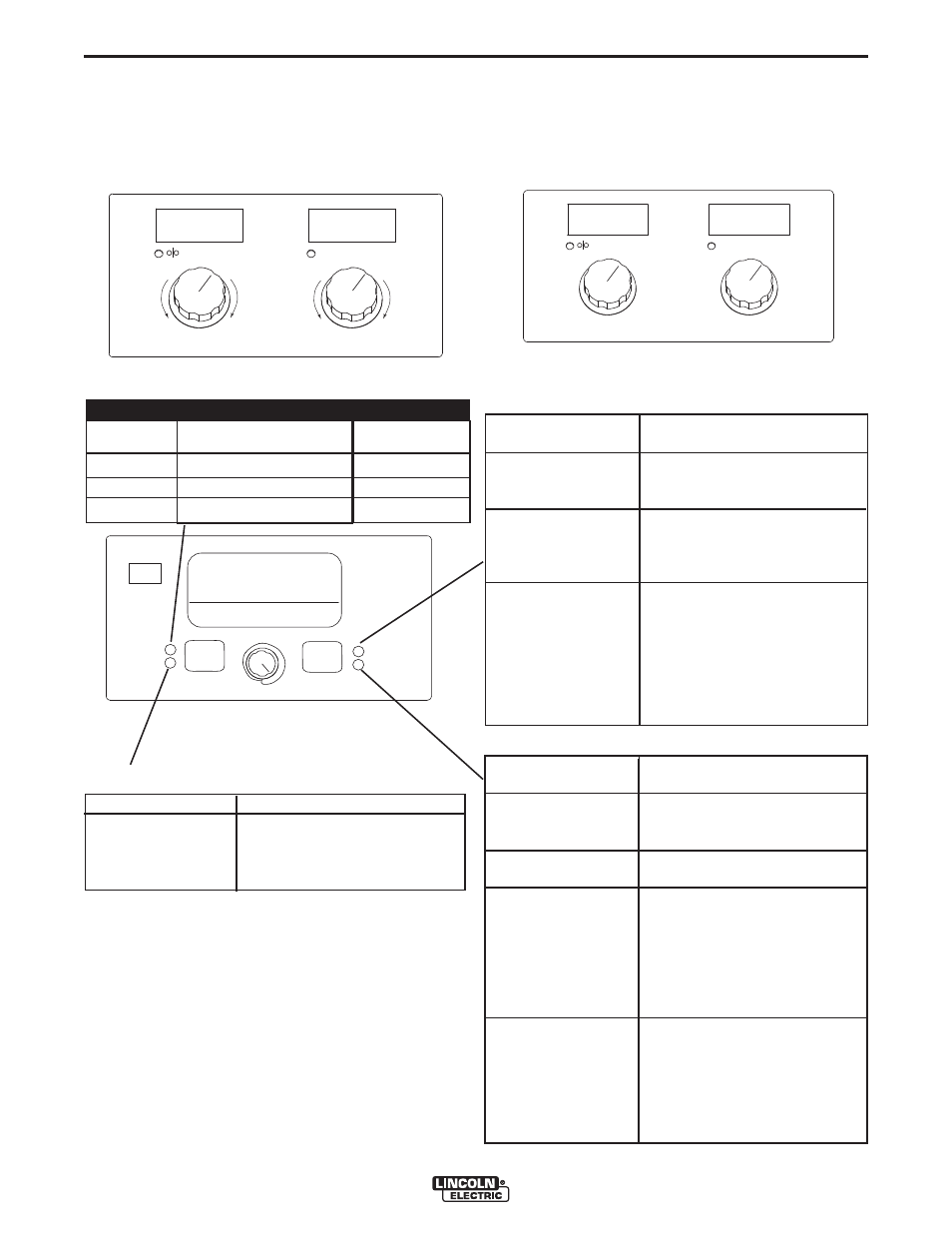

CV NON-SYNERGIC MODES

B-25

OPERATION

B-25

POWER FEED

®

10M SINGLE WIRE FEEDER

DESCRIPTION

Arc Force adjusts the short cir-

cuit current for a soft arc, or for

a forceful, digging arc.

ARC CONTROL

300

25.3

WFS AMPS

VOLTS TRIM

LESS

WFS

MORE

WFS

LESS

VOLTS

MORE

VOLTS

MACHINE FUNCTIONALITY BY WELD PROCESS

CV GMAW/FCAW (NON-SYNERGIC)

Use the following tables to review how the machine functions (output controls, arc control, Start options and weld

options) for the weld modes listed in the top table.

OUTPUT CONTROL KNOBS, WELD MODE 5 & 6

200

2.0

WFS AMPS

VOLTS TRIM

LESS

WFS

MORE

WFS

SHORTER

ARC

LONGER

ARC

OUTPUT CONTROL KNOBS, WELD MODE 40

EFFECT / RANGE

(Soft)-10.0 to

(Crisp)+10.0

EFFECT / RANGE

Preflow Time

0 to 25.0 seconds

Run-In WFS:

Off, 30 to150 in/min.

Start Procedure

0 to 10 seconds

DESCRIPTION

Adjusts the time the gas flows

after the trigger is pulled and

prior to feeding.

Run-In sets the wire feed

speed from the time the trigger

is pulled until an arc is estab-

lished.

The Start Procedure controls the

WFS and Volts for a specified time

at the beginning of the weld.

During the start time, the machine

will ramp up or down from the

Start Procedure to the preset

Welding Procedure.

START OPTIONS

The start Options available in these Non-Synergic CV weld

modes, their adjustment range and function are as follows :

EFFECT / RANGE

Spot Timer:

0 to 120.0 Seconds

Postflow Time

0 to 25.0 seconds

Crater Procedure

(0 TO 10.0 SECONDS)

Burnback:

0 to .25 Seconds

DESCRIPTION

Adjusts the time welding will continue

even if tigger is still pulled. This option

has no effect in 4-Step Trigger Mode.

Adjusts the time that shielding gas

flows after the welding output turns off.

Crater Procedure controls the WFS

and Volts for a specified time at the

end of the weld after the trigger is

released. During the Crater time, the

machine will ramp up or down from the

Weld Procedure to the Crater

Procedure.

The burnback time is the amount of

time that the weld output continues

after the wire stops feeding. It prevents

the wire from sticking in the puddle and

prepares the end of the wire for the

next arc start.

END OPTIONS

START OPTIONS

END OPTIONS

SET

SETUP

IR PORT

STD CV MIG

WAVEFORM CONTROL TECHNOLOGY

5

WELD MODE

ARC CONTROL