Operation – Lincoln Electric IM915 POWER FEED 10M SINGLE WIRE FEEDER User Manual

Page 27

B-5

OPERATION

B-5

1. STATUS LED

The status LED indicates system status. Normal

operation is a steady green light.

Note: During normal power-up, the LED may flash

red and/or green as the equipment performs self tests.

LED condition Definition

Steady green System okay. The power source and

wire feeder are communicating nor-

mally.

Blinking green Occurs during a reset and indicates

the power source is identifying each

component in the system. This is nor-

mal for the first 10 seconds after

power-up, or if the system configura-

tion is changed during operation.

Alternating

Non-recoverable system fault. If the

green and red power source or wire feeder status

LED is flashing any combination of

red and green, errors are present in

the system. Read the error code

before the machine is turned off.

Instructions for reading the error code

are detailed in the Service Manual.

Individual code digits are flashed in

red with a long pause between digits.

If more than one code is present, the

codes will be separated by a green

light.

To clear the error, turn the power

source OFF, and then back ON to

reset. See troubleshooting section.

Steady red

Non recoverable hardware fault.

Generally indicates a problem with

the cables connecting the wire feeder

to the power source.

Blinking red

Not applicable.

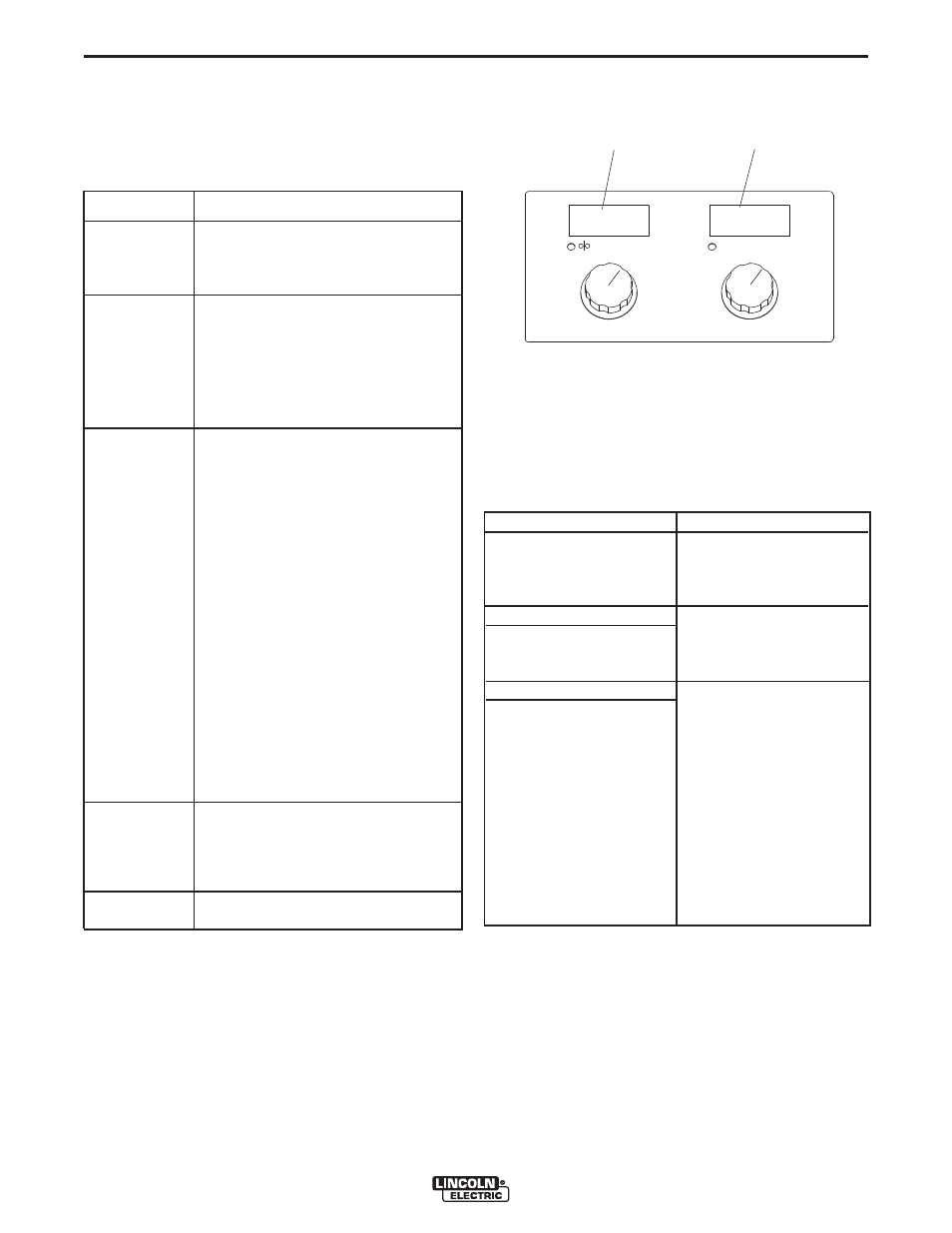

2.

DIGITAL METERS AND OUTPUT

ENCODER KNOBS

(See Figure B.2)

The primary weld procedure settings are controlled

and displayed using digital meters and output encoder

knobs located at the top of the POWER FEED

®

10M

Single Wire Feeder control panel.

POWER FEED

®

10M SINGLE WIRE FEEDER

FIGURE B.2

A. WIRE FEED SPEED/AMMETER DISPLAY

This meter displays either the wire feed speed or cur-

rent value (Amps) depending upon welding process

(Mode) being used and the status of the wire feeder

and power source. Written below the display is "WFS"

and "Amps". An LED light illuminates which value is

being displayed on the meter. The knob below the

meter adjusts the value displayed on the meters.

Prior to Welding

Description

CV Welding Processes Meter displays the preset

WFS value.

CC Welding Processes Meter displays the preset

Amps.

During Welding

An Weld Processes Meter displays displays the

actual average welding

Amps.

After Welding

An Weld Processes The meter holds the actual

current value for 5 sec-

onds. The display blinks to

indicate the POWER

FEED

®

10M Single Wire

Feeder is in the "Hold"

period. If the output is

adjusted while in the

"Hold" period, the POWER

FEED

®

10M Single Wire

Feeder will revert to the

"Prior to welding" display

described above.

Note: If the output knob for the WFS/AMPS is adjust-

ed while the POWER FEED

®

10M Single Wire Feeder

is in the “Hold” period, the POWER FEED

®

10M Single

Wire Feeder will immediately revert to the “Prior to

Welding” display.

The default wire feed speed units are inches/minute and

can be changed to meters/minute by entering the "Set-up

Menu" in this Operation Section. The wire feed speed is

calibrated to within ±2%. Refer to the power source man-

400

263

WFS AMPS

VOLTS TRIM

A

B