Operation, Safety precautions, Warning – Lincoln Electric IM915 POWER FEED 10M SINGLE WIRE FEEDER User Manual

Page 23

B-1

OPERATION

B-1

POWER FEED

®

10M SINGLE WIRE FEEDER

WIRE FEEDER

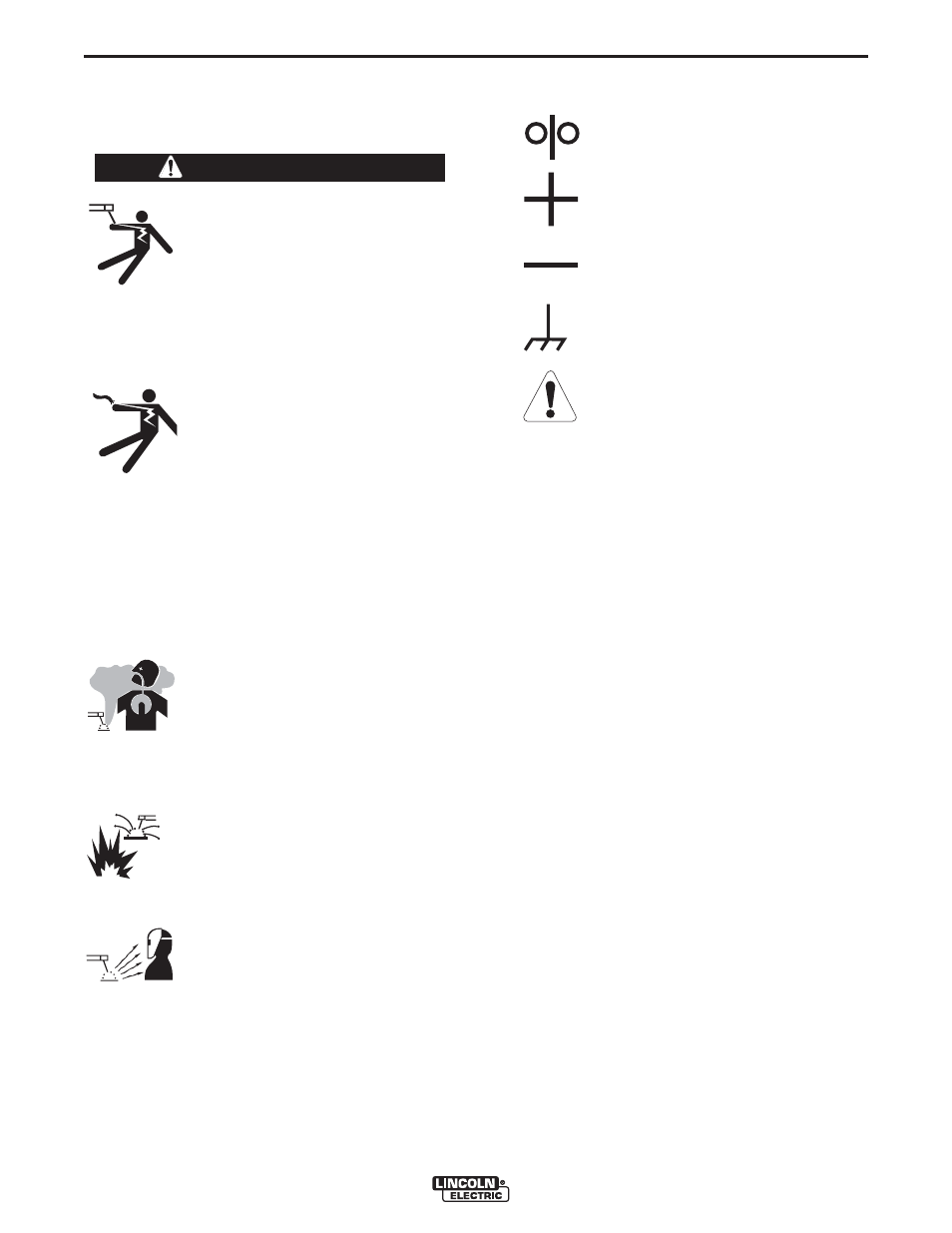

POSITIVE OUTPUT

NEGATIVE OUTPUT

PROTECTIVE

GROUND

WARNING OR

CAUTION

SAFETY PRECAUTIONS

Read this entire section of operating instructions

before operating the machine.

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts

or electrodes with your skin or wet

clothing.

• Insulate yourself from the work and

ground.

• Always wear dry insulating gloves.

• Do not use AC welder if your cloth-

ing, gloves or work area is damp or

if working on, under or inside work-

piece.

Use the following equipment:

-DC manual (stick) welder.

-AC welder with reduced voltage

control.

•

Do not operate with panels

removed.

• Disconnect input power before servicing.

-----------------------------------------------------------------------

READ THIS WARNING, PROTECT YOURSELF &

OTHERS.

FUMES AND GASES can be

dangerous.

• Keep your head out of fumes.

• Use ventilation or exhaust at

the arc,

or both,to keep fumes and gases from

your breathing zone and general area.

WELDING SPARKS can cause fire

or explosion.

• Do not weld near flammable material.

• Do not weld on containers which have

held flammable material.

ARC RAYS can burn.

• Wear eye, ear, and body protection.

ONLY QUALIFIED PERSONS SHOULD INSTALL,

USE OR SERVICE THIS EQUIPMENT. READ AND

FOLLOW THE MANUFACTURER’S INSTRUC-

TIONS, EMPLOYER’S SAFETY PRACTICES AND

MATERIAL SAFETY DATA SHEETS (MSDS) FOR

CONSUMABLES.

-------------------------------------------------------------

WARNING

GRAPHIC SYMBOLS THAT APPEAR ON

THIS MACHINE OR IN THIS MANUAL

DEFINITIONS OF WELDING MODES

NON-SYNERGIC WELDING MODES

• A Non-synergic welding mode requires all welding

process variables to be set by the operator.

SYNERGIC WELDING MODES

• A Synergic welding mode offers the simplicity of

single knob control. The machine will select the cor-

rect voltage and amperage based on the wire feed

speed (WFS) set by the operator.

COMMON WELDING ABBREVIATIONS

WFS - (Wire Feed Speed)

CC - (Constant Current)

CV - (Constant Voltage)

GMAW (MIG) - (Gas Metal Arc Welding)

GMAW-P (MIG) - (Gas Metal Arc Welding)-(Pulse)

GMAW-PP (MIG)-(Gas Metal Arc Welding)-(Pulse-on-Pulse)

GTAW (TIG) - (Gas Tungsten Arc Welding)

SMAW (STICK) - (Shielded Metal Arc Welding)

FCAW (Innershield or Outershield) - (Flux Core Arc Welding)

HF - (High Frequency)

CAG - (Carbon Arc Gouging)