Installation, Warning caution – Lincoln Electric IM733 LN-15 WIRE FEEDER User Manual

Page 10

A-3

INSTALLATION

LN-15 ACROSS THE ARC MODEL

A-3

WELD CABLE CONNECTIONS

ELECTRIC SHOCK CAN KILL.

• ONLY A QUALIFIED ELECTRICIAN SHOULD

CONNECT THE ELECTRODE LEADS TO THE

LN-15. CONNECTIONS SHOULD BE MADE IN

ACCORDANCE WITH ALL LOCAL AND

NATIONAL ELECTRICAL CODES. FAILURE

TO DO SO MAY RESULT IN BODILY INJURY

OR DEATH.

------------------------------------------------------------------------

The size of the electrode cable and work cable must

be sufficient for the maximum weld current and total

cable length used.

To avoid interference problems with other equipment

and to achieve the best possible operation, route all

cables directly to the work or wire feeder. Avoid

excessive lengths and do not coil excess cable. Be

sure the connection to the work makes tight metal-to-

metal electrical contact. (See Table A.1)

ELECTRODE CONNECTION

Route the electrode cable through the strain relief in

the rear of the case. Connect the electrode cable to

the LN-15 input stud using the mounting hardware

provided. Secure the cable by tightening the strain

relief.

All units are supplied with an optional pigtail for cus-

tomers that prefer to make a taped and bolted con-

nection externally.

WORK CONNECTION

Connect a work lead of sufficient size between the

proper output stud on the power source and the work.

Be sure the connection to the work makes tight metal

to metal electrical contact. Poor work lead connec-

tions can result in poor welding performance.

POWER SOURCE CONNECTION

The LN-15 can be used with any DC welding power

source. A constant voltage power source is recom-

mend; however, the LN-15 can also be used with a

constant current power source as long as the open

circuit voltage is less than 110VDC.

TO PREVENT POSSIBLE DAMAGE TO THE LN-15, DO NOT

CONNECT THE LN-15 TO NON-LINCOLN TIG OR SQUARE

WAVE POWER SOURCES. TIG HIGH FREQUENCY SHOULD

NEVER BE APPLIED TO THE LN-15.

------------------------------------------------------------------------------------------

WARNING

CAUTION

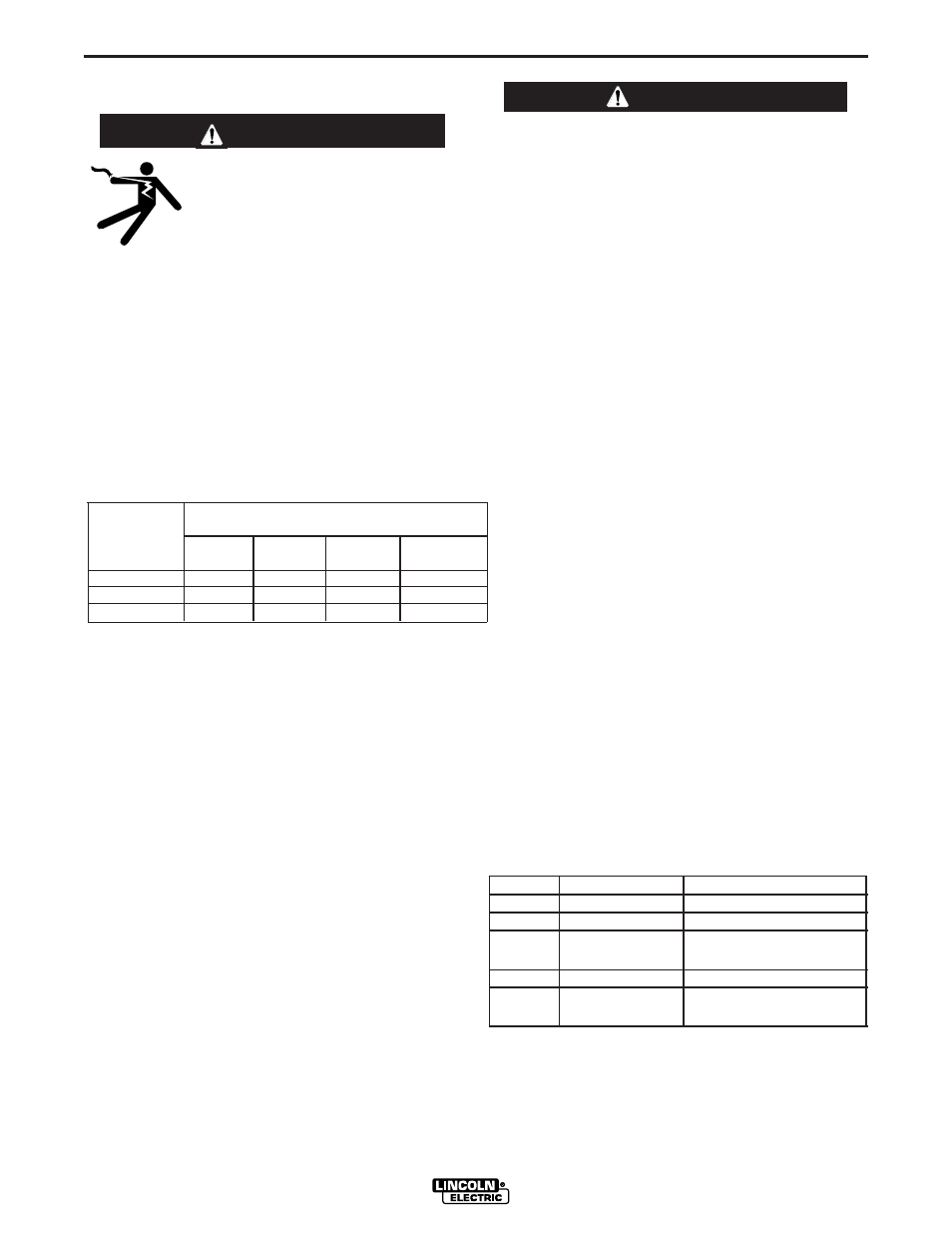

Weld Current

Total Cable Length

60% Duty

(electrode cable + work cable)

Cycle 50 - 100' 100 - 150' 150 - 200' 200 - 250'

(15-30 m) (30 - 46m) (46 - 61m) (61m - 76m)

200 Amps

2 AWG

2 AWG 1 AWG

1/0

300 Amps

1 AWG

1 AWG 1/0

2/0

400 Amps

2/0

2/0

3/0

3/0

TABLE A.1

GUN AND CABLE ASSEMBLIES

A variety of Lincoln 10' (3.0m) or 15' (4.6m) gun and

cable assemblies are available for use with the LN-15,

including the Magnum™ models for GMAW, K126 or

K115 models for Innershield®.

The LN-15 comes factory equipped with a K1500-2

gun connection kit, designed for guns having a

Tweco™ #2-#4 connector. Many other guns can easi-

ly be used with the LN-15 with other K1500 series gun

connection kits.

Gun Cable Connection to the Feeder

Lay the cable out straight. Insert the connector on the

welding conductor cable into the brass bushing on the

front of the wire drive unit. Keep the all mating sur-

faces clean. Make sure it is fully seated and tighten

the thumb screw.

Connect the control cable plug into the 5 pin recepta-

cle on the front panel of the wire feeder.

ELECTRODE POLARITY

The LN-15 automatically adjusts for positive and neg-

ative polarity. When welding with negative polarity

procedures, the voltmeter will display a "-" sign; exam-

ple "-23.6" Volts.

CONTROL CABLE CONNECTIONS

Across the Arc LN-15 models do not use a control

cable.

Table A.2 Trigger Connector J1 (5 Pin)

PIN

Lead #

Function

A

556

Trigger

B

-

Not used

C

554

Trigger/ 83%

Procedure ground

D

555

83% Procedure

E

554

Trigger/ 83%

Procedure ground